Zinc Plating

Zinc Plating for Industrial-Grade Protection

Extend the Life of Your Metal Parts with Corrosion-Resistant Coatings

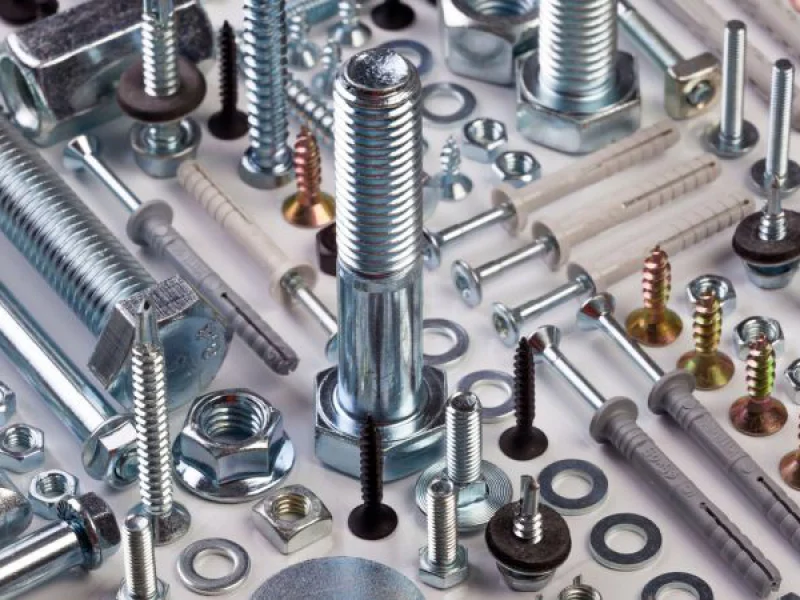

Rust and corrosion are the silent killers of productivity. Whether you’re manufacturing fasteners, brackets, or automotive components, exposure to moisture and air can ruin your parts—and your reputation.

That’s why Fiesco Precision offers high-quality zinc plating services that provide a strong, affordable shield against corrosion. Trusted by manufacturers across Mexico and the USA, our zinc finishes help you lower replacement costs, boost product life, and meet regulatory standards.

What Is Zinc Plating?

Zinc plating is the process of electrochemically applying a thin layer of zinc onto the surface of a metal component—typically steel or iron. This sacrificial coating slows down corrosion by acting as the first line of defense against oxidation and harsh environments.

Unlike other coatings, zinc not only shields the metal but also offers self-healing properties that continue to protect even after scratches or dents.

Why Choose Zinc Plating?

Here’s why engineers and manufacturers choose zinc-plated parts again and again:

✔️ Corrosion Protection (especially in humid or coastal environments)

✔️ Improved Appearance – Clean, bright, or matte finish options

✔️ Increased Longevity of metal components

✔️ Excellent Paint & Adhesive Base

✔️ Cost-Effective for high-volume parts

✔️ RoHS-Compliant Options available upon request

Ideal for High-Demand Industries

Zinc plating is a popular finish in industries where durability, cost-efficiency, and appearance matter:

- Automotive – Bolts, brackets, clamps, and panels

- Construction – Structural supports, anchors, and fittings

- Consumer Products – Appliances, hand tools, hardware

- Electronics – Shielded enclosures, fasteners

- Agriculture & Food Processing – Machinery, cages, and conveyor parts

Get a Quote today

Get a fast, accurate quote tailored to your project needs.

Our Zinc Plating Process

At Fiesco, precision isn’t just in our name—it’s in every step of our plating line.

- Thorough Cleaning & Degreasing

To ensure proper adhesion and eliminate contaminants. - Acid Pickling

Removes surface oxides for optimal electroplating performance. - Zinc Electroplating

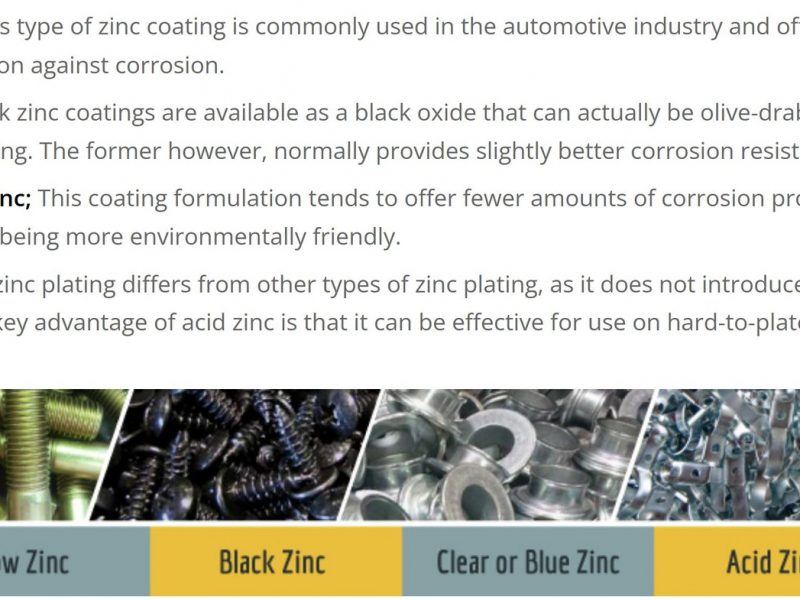

We apply a consistent zinc layer using controlled current and time settings. - Optional Passivation/Chromating

Enhances corrosion resistance and adds a color tone (clear, yellow, black).

Drying & Inspection

Every part is visually inspected and tested for coating integrity and thickness.

Built for Performance, Ready for Volume

From low-volume runs to mass production, Fiesco Precision is your zinc plating partner of choice.

We guarantee:

- Reliable turnarounds for urgent production schedules

- Uniform finishes, even on complex geometries

- Batch traceability and consistent thickness control

Compliance with ASTM, ISO, and RoHS standards when required

Ready to protect your investment?

Contact Fiesco today to learn more about our zinc plating services and request a custom quote.

Use Softer, Smarter Metals

Annealing isn’t just about softening a part. It’s about unlocking its full potential—ensuring it responds predictably to forming, machining, or final use.

If you’re dealing with hard-to-cut metals, inconsistent forming results, or cracking issues, annealing is the step that brings everything back in line.

At Fiesco Precision, we help you produce metal components that perform reliably—because reliability starts at the core.

Let’s talk about your annealing needs and build better from the inside out.