CNC Machining Center

Precision Machining Services

High Quality CNC Machining services

Fiesco Precision delivers high-quality CNC machining with accuracy, speed, and cost efficiency. From prototypes to large-scale production, we ensure your parts are made right the first time.

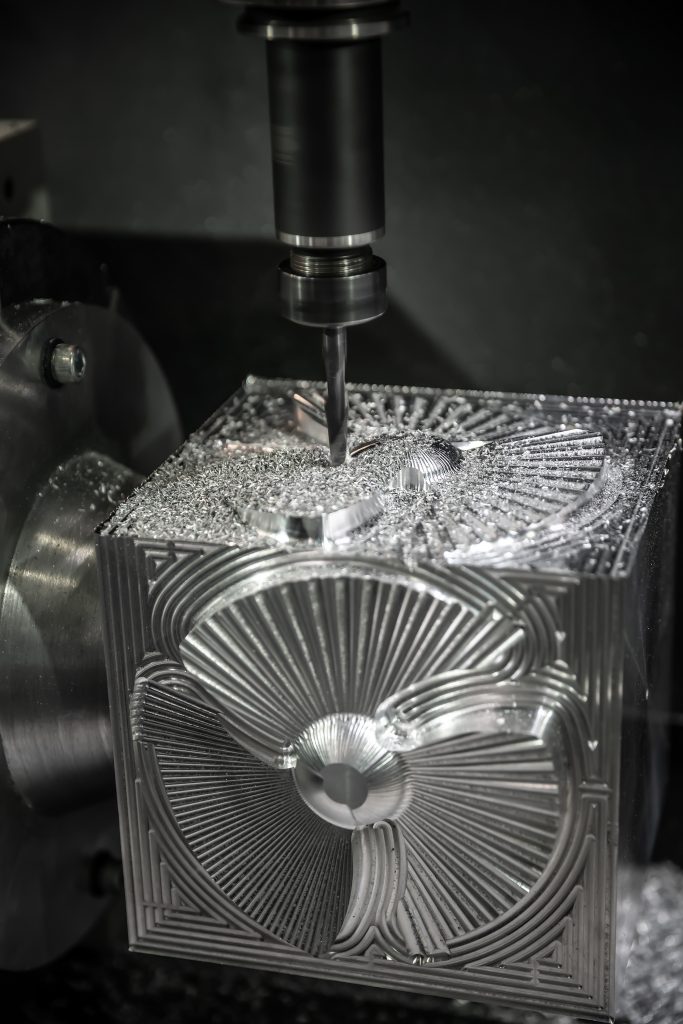

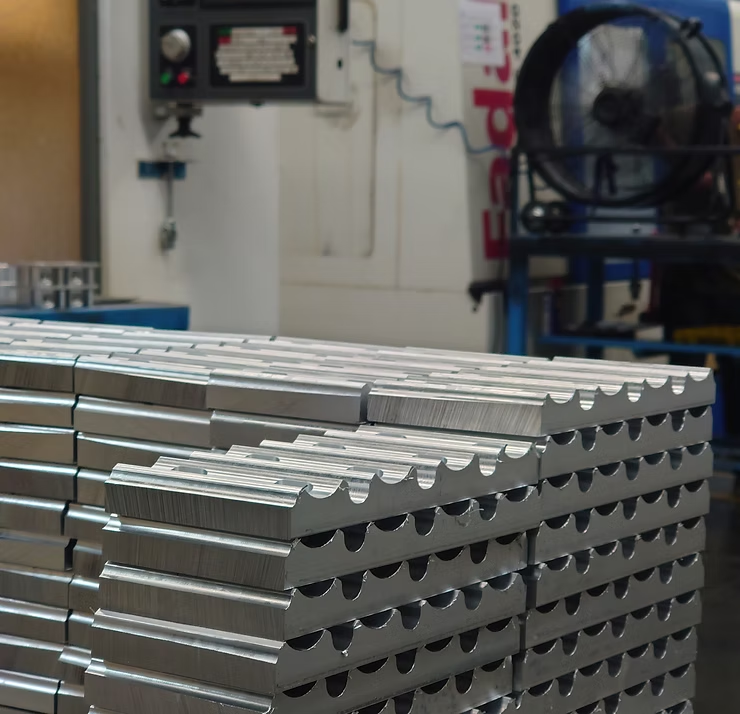

CNC Milling

Our CNC machining centers allow us to machine flat surfaces, cavities, 3D contours, and complex parts with high repeatability and dimensional accuracy.

Four- and five-axis machining enables us to work multiple faces in a single setup, improving precision and reducing rework. From functional prototypes to full-scale production runs, we meet the highest industrial quality standards.

3-Day Prototypes & Small Batch Runs

- Fast deliveries starting in 3 days

- Quick and flexible response

Standard Production

- Consistent scheduled deliveries

- Reliable and flexible lead times

- Carbon steel, alloy steel

- Stainless steel, aluminum

- Titanium

- Copper

- Brass

- Nylon

- Delrin (POM)

- UHMW

- PTFE (Teflon)

- Polycarbonate

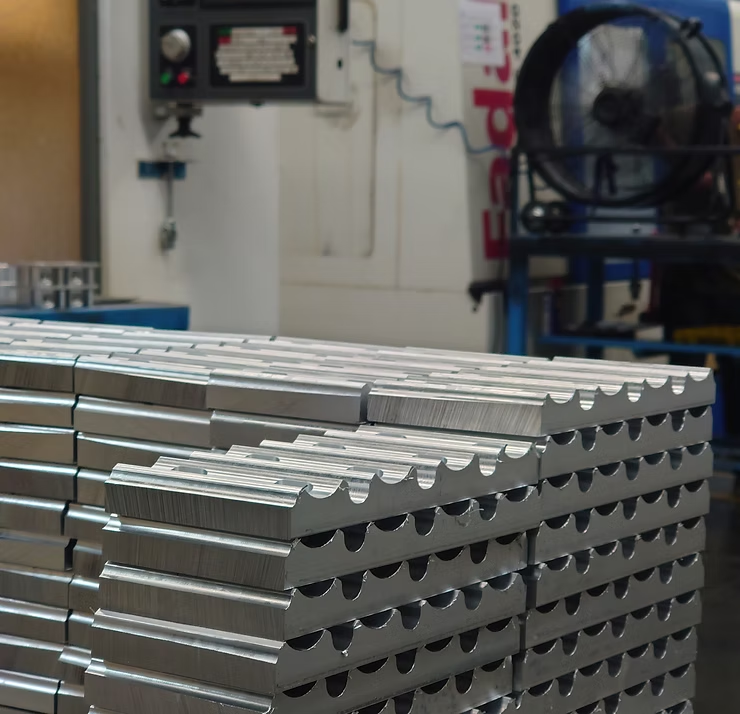

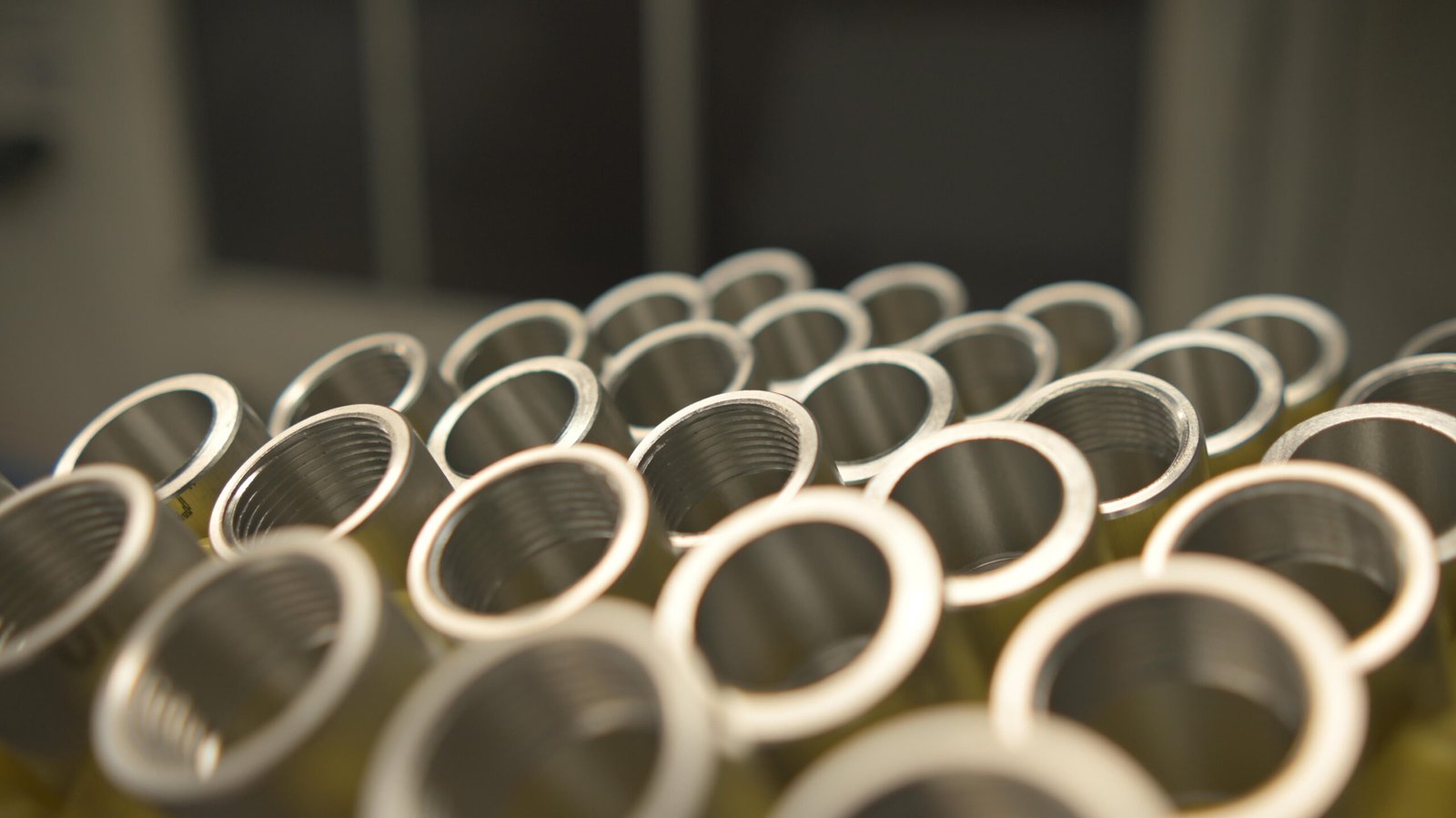

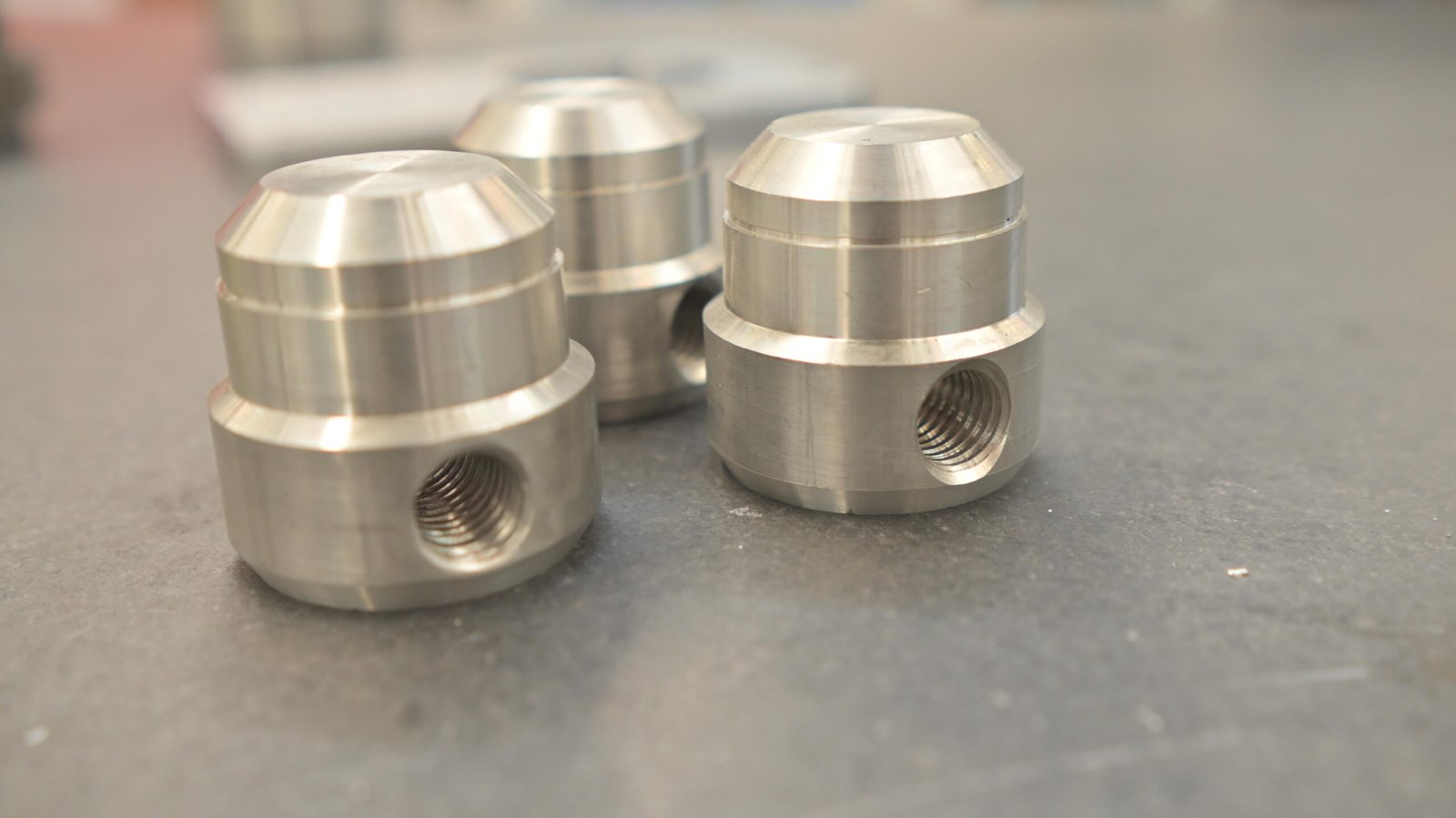

CNC Lathes

With our CNC lathes, we manufacture cylindrical, conical, threaded, and high-complexity components. The integration of additional axes and live tooling allows us to perform combined turning and milling operations, optimizing production times.

We focus on meeting our clients’ requirements on time and to specification. Machining in 2, 3, and 4 axes, with repeatability ideal for serial production and full CAD/CAM integration.

3-Day Prototypes & Small Batch Runs

- Deliveries starting in 3 days

- Fast and flexible response

Standard Production

- Consistent scheduled deliveries

- Reliable and flexible lead times

Metals

- Carbon steel, alloy steel

- Stainless steel, aluminum, titanium

- Titanium, copper

- Copper

- Brass

Plastics & Composites

- Nylon

- Delrin (POM)

- UHMW

- PTFE (Teflon)

- Polycarbonate

Conventional Machining

At FIESCO, we provide specialized conventional machining services focused on the fabrication, repair, and adjustment of metal components for industrial applications.

We combine technical expertise, robust machinery, and skilled labor to deliver reliable solutions whenever speed, precision, and flexibility are required.

We are an ideal partner for single parts, urgent prototypes, and industrial maintenance work, as well as for special components that demand immediate attention and strict compliance with technical specifications.

Prototypes & Small Batch Runs

- Deliveries starting in 2 days

- Fast response for urgent jobs

- Flexible adjustments and repairs

Standard Production

- Consistent, scheduled deliveries

- Reliable on-time performance

- Ongoing support based on customer requirements

Wire EDM

At Fiesco, we provide wire EDM services ideal for producing complex geometries, fine profiles, and parts with high dimensional accuracy, even in hardened or high-hardness materials.

Our clients include the tooling and die, automotive, aerospace, medical, electronics, and metalworking industries, where tight tolerances and high-quality finishes are essential.

Request your quote today and achieve high-precision cuts for complex components.

4-Day Delivery for Prototypes and Small Batches

Standard Production with Scheduled, Consistent Deliveries

| Capability | Range |

|---|---|

| X–Y Travel | 300 – 800 mm |

| Z Travel (Cut Height) | 150 – 400 mm |

| Wire Diameter | 0.1 – 0.3 mm |

| Tolerance | ±0.002 mm |

| Surface Finish | Ra 0.2 – 1 µm |

| Taper Angle | Up to ±30° |

Processable Materials: Carbon steel, stainless steel, hardened steels, tool steels, aluminum, copper, titanium, and tungsten carbide. ⚠️

Surface Grinding

At Fiesco, we provide professional surface grinding services using both conventional and CNC equipment, ensuring high quality, repeatability, and maximum dimensional accuracy in every project.

Our process is ideal for industries that require perfectly leveled surfaces, such as automotive, aerospace, metalworking, tooling and dies, heavy manufacturing, and industrial machinery.

3-Day Delivery for Prototypes and Small Batches

Standard Production with Scheduled Deliveries

| Specification | Range |

|---|---|

| Table Length | 500 mm – 6,000 mm |

| Table Width | 200 mm – 1,500 mm |

| Maximum Load | Up to 10,000 kg |

| Precision | ±0.001 mm |

| Control Type | Manual and CNC |

Centerless Grinding

We offer high-precision centerless grinding services using modern equipment, ensuring consistent dimensional control and the capacity to handle high-volume production.

Request your quote today and optimize your processes with our industrial centerless grinding solutions.

3-Day Delivery for Prototypes and Small Batches

Standard Production with Scheduled, Consistent Deliveries

| Specification | Range |

|---|---|

| Part Diameter | 0.5 mm – 150 mm |

| Part Length | Unlimited (through-feed) |

| Dimensional Tolerance | ±0.001 mm |

| Surface Finish | Ra 0.2 – 0.8 µm |

| Grinding Speed | High, continuous process |

| Operating Modes | Through-feed, in-feed, end-feed |

Sinker EDM (Ram EDM)

We provide high-precision sinker EDM services using advanced machinery, specialized electrodes, and strict dimensional control.

Our clients include tooling and die, automotive, aerospace, medical, and electronics industries, where fine finishes, tight tolerances, and repeatability are critical.

Request your quote today and produce complex geometries with our industrial sinker EDM solutions.

4-Day Delivery for Prototypes and Small Batches

Standard Production with Scheduled, Consistent Deliveries

| Specification | Range |

|---|---|

| X–Y Travel | 300 – 1,000 mm |

| Z Travel | 200 – 600 mm |

| Maximum Part Weight | Up to 3,000 kg |

| Tolerance | ±0.002 mm |

| Surface Finish | Ra 0.2 – 1.5 µm |

| Electrode Type | Graphite / Copper |

Processable Materials: Carbon steel, stainless steel, hardened steels, tool steels, aluminum, copper, titanium, and tungsten carbide.

⚠️ Note: The material must be electrically conductive.

High-Precision CNC Services for California Manufacturers

Our CNC machining services are tailored for industries requiring complex, accurate, and repeatable parts. With our experienced engineering team and top-tier equipment, we offer solutions that go from design to large-batch production with consistent quality.

Advantages of CNC Machining

Our CNC machining cutting process ensures maximum raw material utilization and optimized production times.

Usage of programmed numerical codes, with high precision, bring consistent and accurate results for every order.

Capacity & Material Capabilities

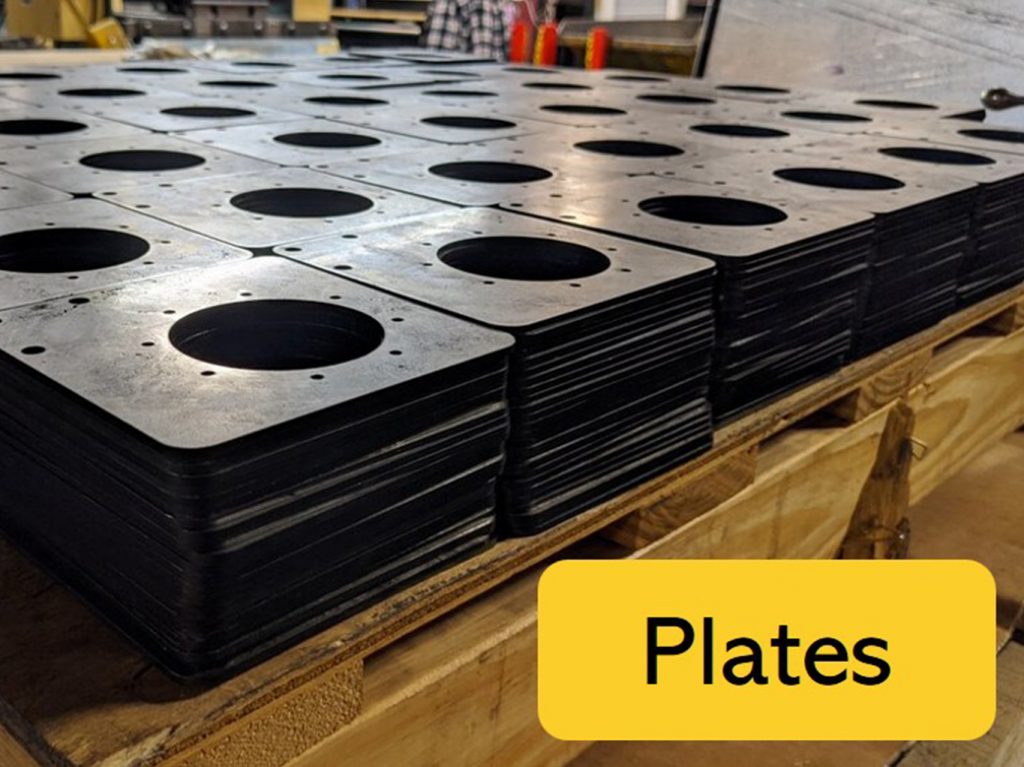

Plates of

Min 16“ x 20”

Max 20” x 50”

Our CNC capabilities include:

- MILL – Precision milling for parts with tight tolerances

- LATHE – High-speed turning services for cylindrical components

- LARGE PARTS – Machining of oversized components with strict precision

- MARKING – Part engraving and traceability markings

- LABELING – Industrial labeling integrated into the production line

- WELDING – High-quality welds for assembly and fabrication

- ASSEMBLY – Final mechanical assembly to streamline production

We proudly serve industries throughout Southern California, including San Diego, Riverside, Los Angeles, and surrounding areas.

Comprehensive CNC Machining Solutions

We deliver precision CNC machining solutions that support demanding industrial operations, combining advanced manufacturing capabilities, strict quality control, and engineering expertise.

Our processes are designed to ensure dimensional accuracy, repeatability, and reliable performance across a wide range of production requirements, from prototyping to series manufacturing.

Why choose Fiesco?

- Tight tolerances maintained

- Fast and reliable turnaround

- Scalable production capacity

- Engineering-driven processes

- Consistent, repeatable quality

- Binational operational support

CNC Manufacturing services from mexico to The United States

Full-Service Sheet Metal Work From Baja California to the United States

We provide industrial manufacturing and CNC machining services from Mexico, supporting U.S. companies with cost-effective production, fast lead times, and reliable cross-border operations.

Our binational model allows U.S. buyers to access high-quality manufacturing while maintaining close communication, engineering support, and consistent delivery standards.

Explore Our Specialized CNC Machining Equipment

At Fiesco Precision, we operate a wide range of CNC machining centers equipped to handle complex projects with accuracy and speed. Our advanced machinery allows us to produce prototypes, custom parts, and high-volume orders while maintaining consistent precision and reliability.

With this technology, we can meet diverse industry requirements and deliver parts on time, every time.

Fiesco Precision

Material Selection & Cost Optimization

Choosing the right material is critical for both performance and cost efficiency.

At Fiesco Precision, our engineering team works with clients to evaluate design requirements, industry standards, and budget considerations to recommend the most effective material options.

This ensures durability, functionality, and cost control across every project.

Smarter Choices, Better Results

Through detailed analysis and supplier integration, we identify materials that balance strength, machinability, and price.

By optimizing both the selection and usage of raw materials, we help reduce waste, control production costs, and keep your projects within budget without compromising on quality.

Our CNC Machining Inventory

6 FADAL 4020

2 FADAL 2216

4 FADAL 3016

2 FADAL 2016

1 FADAL 5020

Other Integrated Services

Let’s bring your vision to life with high-precision CNC Machining.

Need precision parts, fast and reliable? Fiesco Precision delivers on-time CNC machining solutions tailored to your specs and budget.