Nickel Plating

Nickel Plating Services

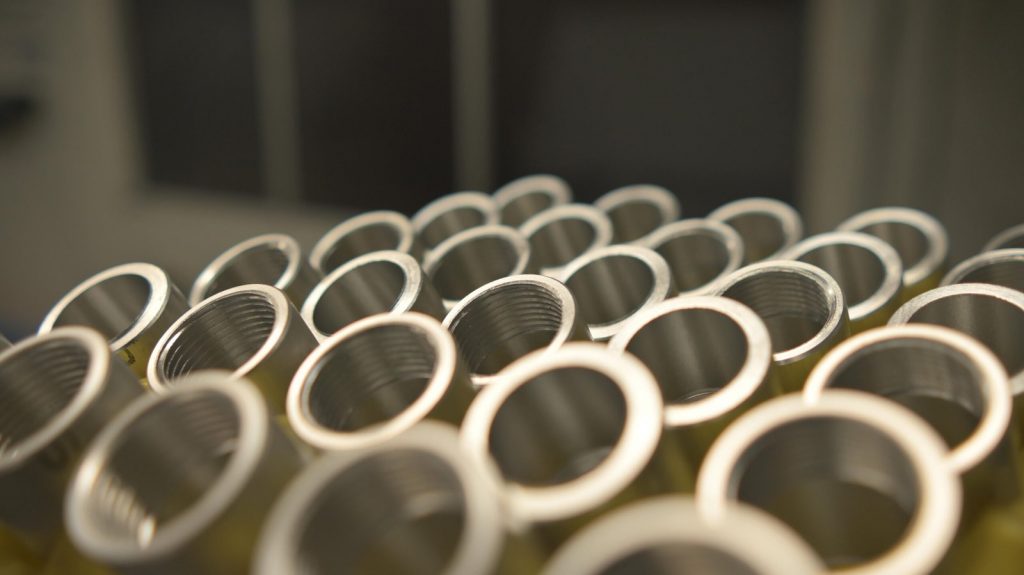

Enhanced Protection with a Polished Finish

When your components require reliable corrosion resistance, aesthetic appeal, and improved durability, Nickel Plating is a proven solution. At Fiesco, we specialize in precision nickel plating for metal parts across a wide range of industries—offering consistent coverage, high-quality adhesion, and long-lasting performance.

From electronics to automotive, our process ensures your parts are protected, functional, and ready for the demands of your market.

difference. At Fiesco Precision, we use precision-controlled annealing processes to give your materials the flexibility, softness, and structural consistency needed for downstream operations and long-term performance.

What Is Nickel Plating?

Nickel plating is a surface finishing process that involves depositing a thin layer of nickel onto a metal object. This is done using electrochemical or electroless methods, depending on the part geometry, material, and desired properties.

The result is a smooth, bright, and corrosion-resistant layer that not only protects the base material but also enhances its appearance and wear life.

Advantages of Nickel Plating

Choosing Fiesco for your nickel plating needs gives you access to:

✅ Excellent corrosion resistance against moisture, chemicals, and wear

✅ High hardness to reduce surface damage

✅ Improved electrical conductivity

✅ Increased surface lubricity

✅ Smooth, mirror-like or matte finish (customizable)

✅ Compatibility with various base metals: steel, brass, copper, aluminum, etc.

Where Nickel Plating Shines

This finish is widely used across industries requiring both aesthetics and function:

- Automotive & Transport: Pistons, engine parts, fasteners

- Electronics: Connectors, sensors, terminals

- Appliances: Handles, knobs, frames

- Medical Devices: Surgical tools, housings

- Aerospace: Structural components, fittings

- Consumer Goods: Jewelry, eyewear, hardware

Whether you need a decorative finish or a functional protective layer, nickel plating is a versatile option that adds value to every part.

Get a Quote today

Get a fast, accurate quote tailored to your project needs.

Our Nickel Plating Process

At Fiesco, our state-of-the-art facilities ensure tight process control, reliable turnaround, and repeatable results:

- Degreasing & Cleaning

Removes oils, dirt, and residues to ensure proper bonding. - Pickling / Etching

Prepares the surface for even deposition. - Nickel Deposition

Using an electrolytic bath, nickel is evenly applied to all exposed surfaces. - Rinsing & Drying

Ensures cleanliness and finish integrity. - Optional Post-Treatment

Includes passivation, sealing, or heat treatment depending on part requirements.

We can offer both bright nickel (for decorative or reflective surfaces) and satin/matte nickel (for subtle, non-glare finishes). Thickness and hardness are tailored to your specific application.

Why Fiesco?

- Precision Process: Controlled environment and certified plating chemistry

- Full-Service Fabrication: Combine nickel plating with our CNC machining, laser cutting, or welding

- Fast Turnaround: For urgent builds or large-volume runs

- Serving Mexico & USA: Ideal for industries in Baja California, Querétaro, Arizona, and Texas

- Documentation Available: We provide full traceability and finish certifications when required

We’re not just another finishing shop—we’re a manufacturing partner who understands your timelines, tolerances, and performance goals.