Automotive Industry CNC Services in california

High-Quality CNC Services for the Automotive Industry

Precision machining, tooling, and component production to support high-performance automotive manufacturing.

Supporting Automotive Manufacturing in California Since 1998

Our experience in the manufacturing industry dates back to 1998, working with clients such as Hyundai, Toyota, and manufacturing subsidiaries as manufacturers of vehicle accessories and complements, as well as high-demand agricultural implements.

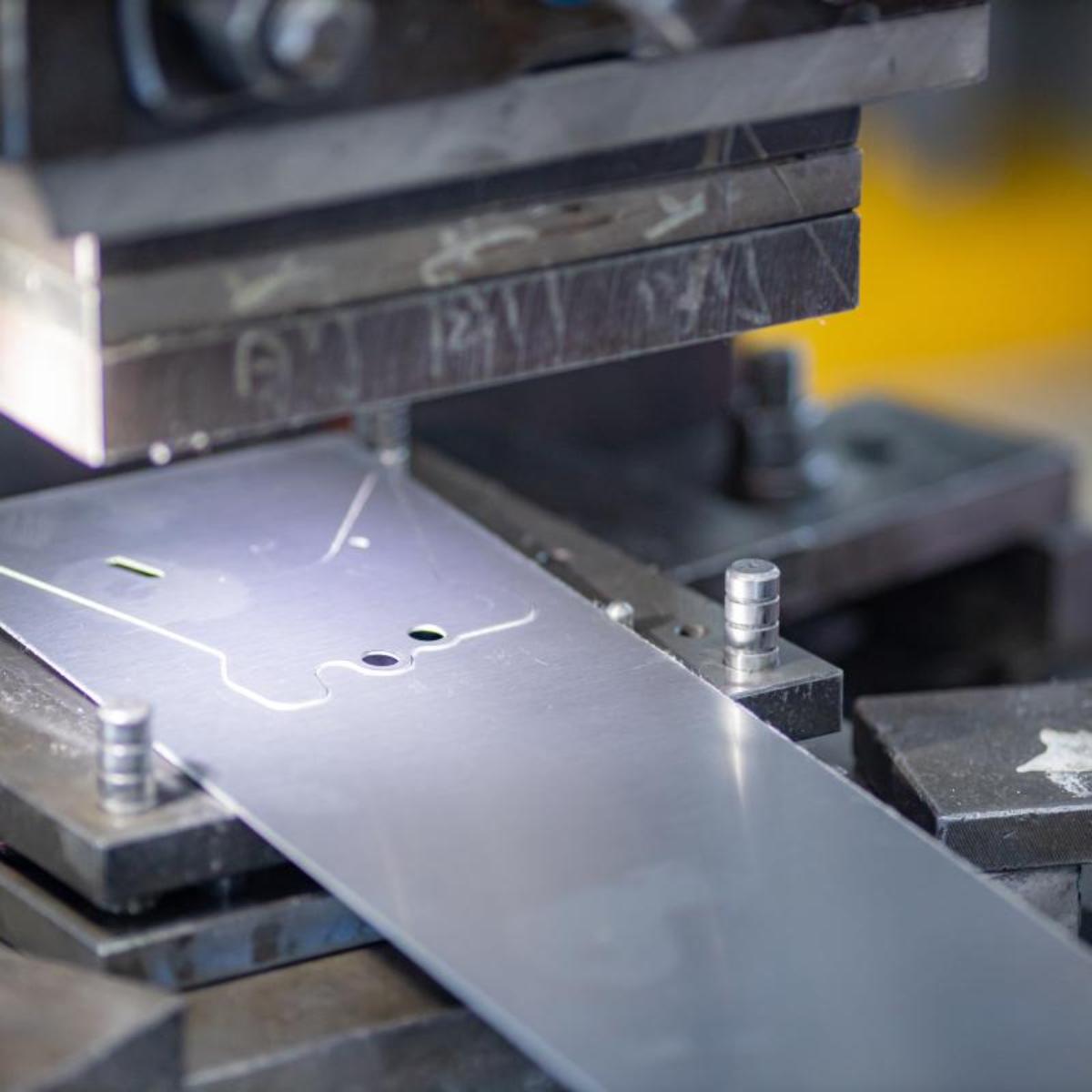

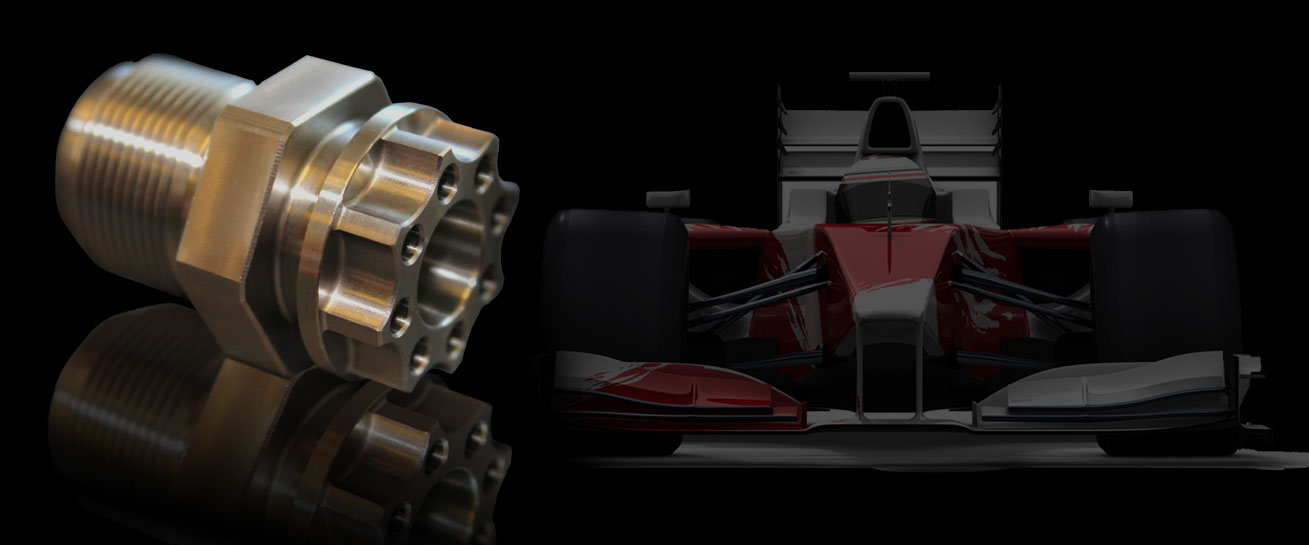

We have worked closely with this industry in the manufacture of process tooling, using high-alloy tool steels such as punches, molds, and stamping dies, as well as machine-grade steels for preforming molds.

We collaborate directly with automotive manufacturers to enhance tooling accuracy, reduce downtime, and support continuous improvement in production lines.

Tooling & Production Equipment for the Automotive Sector

We also have experience in laser cutting and medium- to high-demand machining for agricultural and industrial implements.

We are an expert engineering team supporting various branches of industry in design, technical support, process improvement, and continuous improvement, as well as in orchestrating the external products and services necessary for integrating the services required by our customers.

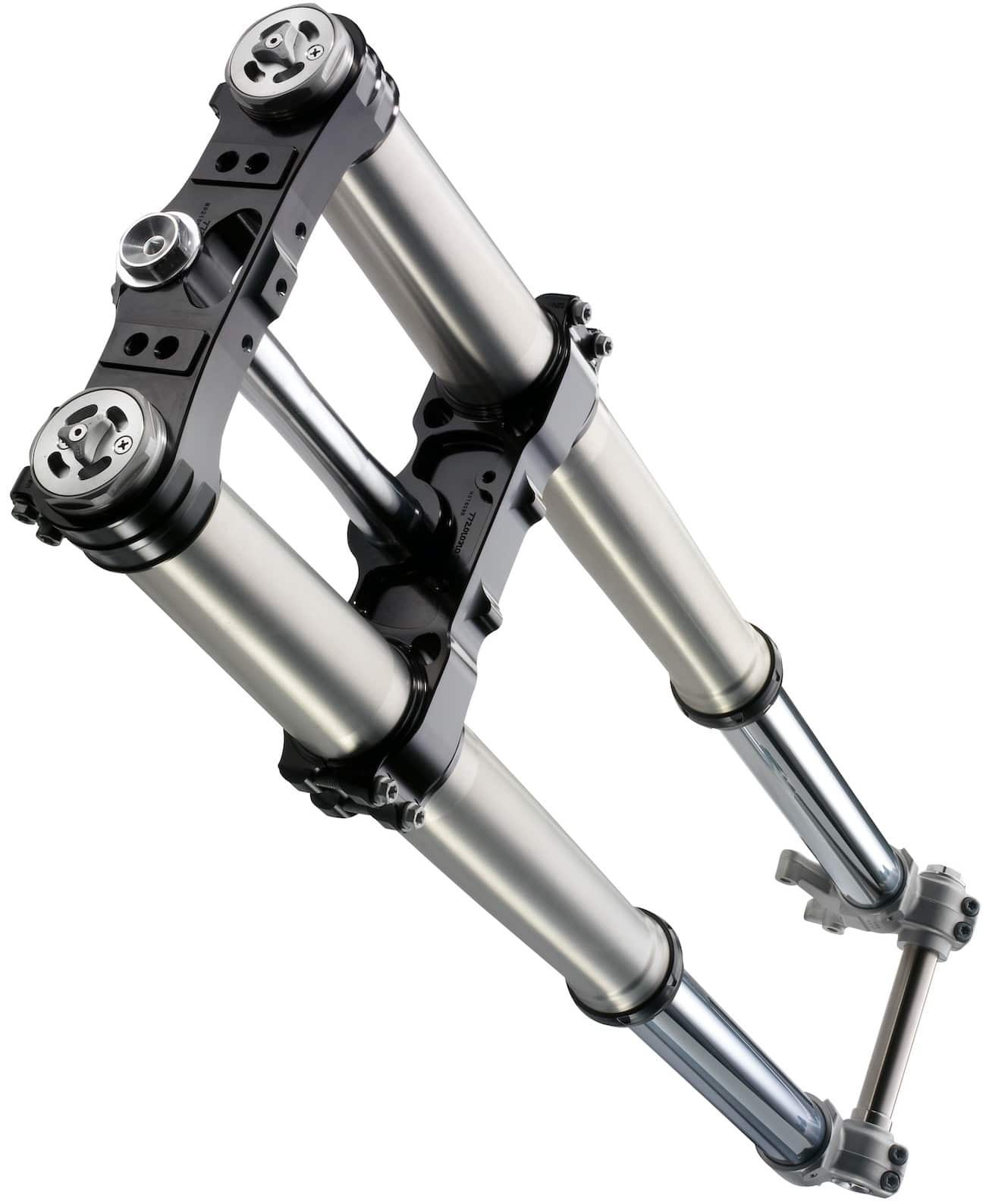

We also manufacture machine parts such as gears, racks, cylinders, hydraulic and pneumatic components, worm gears, conveyors, and lifting equipment for assembly operations.

Quality is at the heart of everything we do at Fiesco Precision

Capabilities for Large and Complex Components

Automotive production often requires oversized or long components, and Fiesco Precision is equipped for both machining and laser cutting of parts up to 18 meters in length.

This capability supports manufacturers that require long structural elements, automation components, conveyors, or specialized assemblies used in large-scale production systems.

Applications include:

Long-bed machining for structural automotive components

Laser cutting for extended profiles and formed parts

Precision components for material handling and automated movement systems

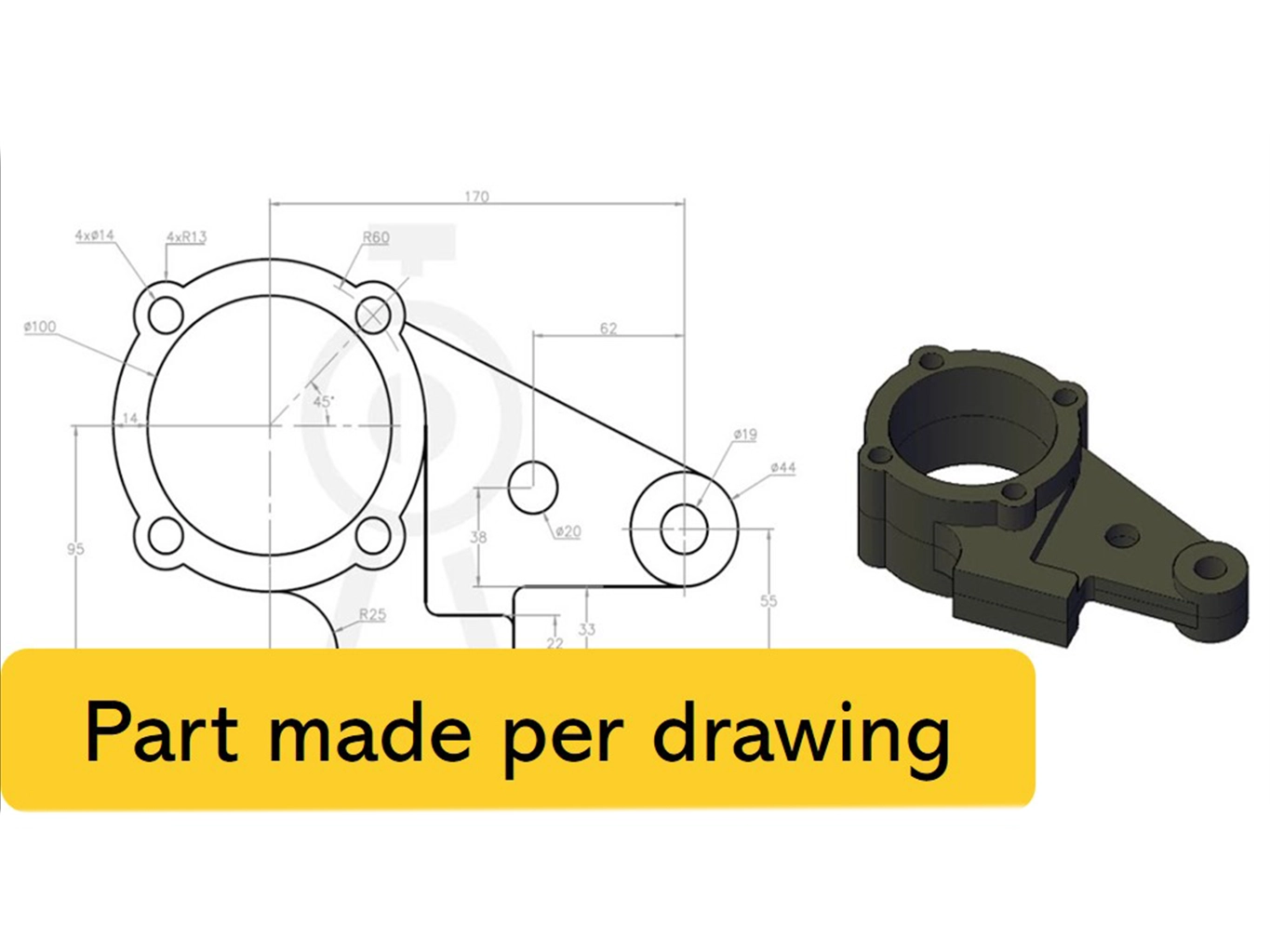

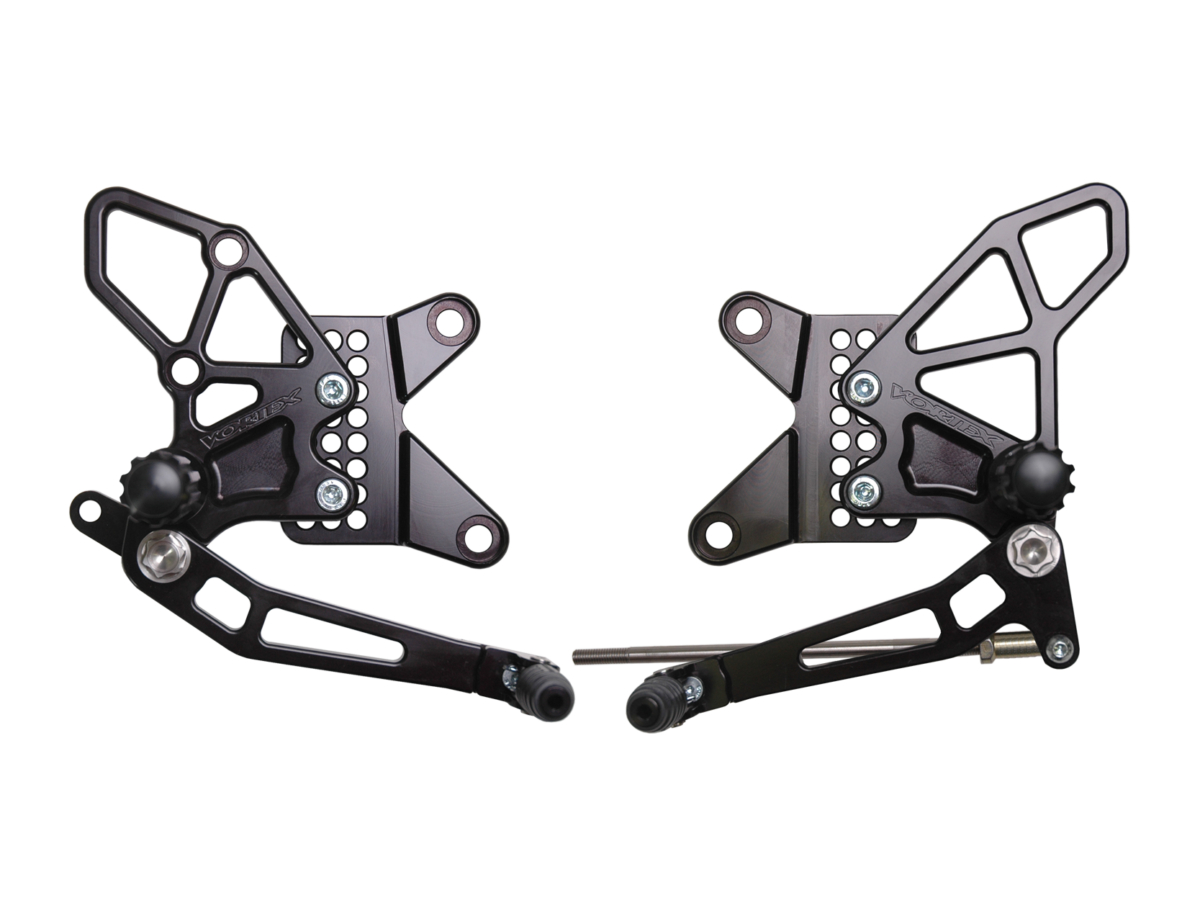

Automotive Customized Parts

Materials We Work With

We work with tool steels, machinery steels, high-strength alloys, aluminum, and engineering plastics required for automotive-grade durability. These materials allow us to produce components that withstand mechanical stress, long production cycles, and demanding environmental conditions.

Our approach ensures each component meets dimensional accuracy, wear resistance, and structural integrity requirements.

Engineering Collaboration for Automotive Processes

Our engineering team partners with automotive manufacturers to refine tooling, improve equipment performance, and support efficient assembly processes.

We provide technical solutions for spare parts, process improvements, and system optimization, helping plants increase output and maintain consistent performance.

This collaborative approach ensures compatibility, precision, and long-term operational reliability.

Reliable Automotive CNC Manufacturing in California

Get high-precision tooling, components, and production equipment engineered to support the demanding needs of the automotive industry.