Soldadura

Soluciones de Soldadura avanzada

Soluciones Avanzadas de Soldadura y Fabricación CNC

En FIESCO, cerramos la brecha entre la soldadura de alta resistencia y la precisión CNC. Nuestro enfoque integrado garantiza que cada ensamble soldado comience con componentes mecanizados por CNC para garantizar un ajuste perfecto (fit-up), reduciendo el estrés interno y asegurando la integridad estructural del producto final.

Servicio de soldadura

Contamos con una amplia capacidad instalada y un estricto control de procesos para todo tipo de soldadura, bajo normas nacionales e internacionales. Operamos bajo un sistema de gestión de calidad para asegurar que sus requerimientos se cumplan a tiempo y según las especificaciones técnicas.

Nuestro experimentado equipo de ingeniería está listo para asesorarle sin costo, resolviendo dudas técnicas y trabajando en conjunto para garantizar la calidad del producto—desde los primeros artículos (FAIs) hasta la producción total.

Solicite su cotización hoy mismo y optimice su producción con nuestros servicios profesionales de soldadura.

| Tipo de Soldadura | Descripción | Aplicación Típica | Espesor Recomendado |

|---|---|---|---|

| MIG (GMAW) | Proceso semiautomático de alta productividad | Estructuras, ensambles generales, producción media a alta | 0.8 – 6.0 mm |

| TIG (GTAW) | Soldadura de alta precisión con excelente acabado | Piezas visibles, componentes de precisión, tolerancias críticas | 0.5 – 4.0 mm |

| Punto (Resistencia) | Unión de material por presión sin metal de aportación | Láminas traslapadas, ensamble rápido | 0.5 – 3.0 mm por lámina |

| Láser | Soldadura de alta energía con distorsión térmica mínima | Piezas de alto valor y alta estética | 0.3 – 3.0 mm |

| Arco Manual (SMAW) | Proceso de soldadura manual versátil | Reparaciones y estructuras simples | 2.0 – 10 mm |

- Acero al carbono

- Acero Inoxidable

- Aluminio

- Bronce y cobre

- Aleaciones (aceros para herramientas, Inconel, etc.)

High-Precision Welding Services

We deliver high-precision welding solutions that support demanding industrial operations, combining advanced joining technology, CNC-integrated fixtures, and strict quality control to ensure consistent structural integrity.

Our welding processes are designed to achieve high-strength bonds, clean seams, and reliable dimensional accuracy across a wide range of production requirements, from CNC-machined prototypes to full-scale industrial manufacturing.

Why Choose Fiesco for Welding services?

- CNC-Integrated Precision

- Advanced Technology

- Multi-Material Expertise

- Strict Quality Control

- Prototype to Production

- Strategic Nearshoring

Welding services from mexico to The United States

Full-Service Welding Solutions From Baja California to the United States

Operating from Baja California, we provide high-precision welding solutions that support U.S. manufacturers with high-strength joints, CNC-accurate fixturing, and fast turnaround times.

Our welding and fabrication processes are designed to meet the most demanding industrial requirements while maintaining cost efficiency and consistent structural integrity across every assembly.

Through our binational operating model, U.S. companies benefit from reliable cross-border manufacturing, close communication, and engineering support that ensures precise results from CNC-integrated prototyping to full-scale production.

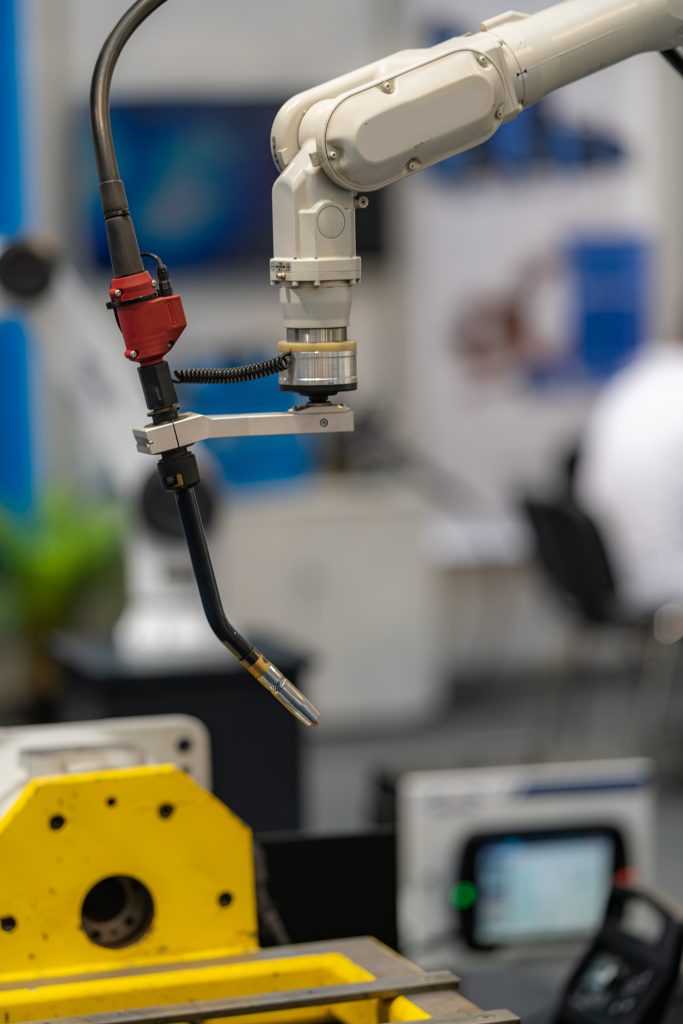

Explore Our Advanced Welding Technology

At FIESCO, we operate state-of-the-art welding systems designed to handle complex assembly requirements with accuracy and efficiency. Our advanced equipment, integrated with CNC-machined fixtures, allows us to process a wide range of materials, deliver high-strength clean seams, and support both custom prototypes and high-volume production runs.

Through this technology, we meet diverse industry requirements while ensuring consistent structural quality, fast turnaround times, and reliable on-time delivery to our U.S. partners.

Fiesco Precision

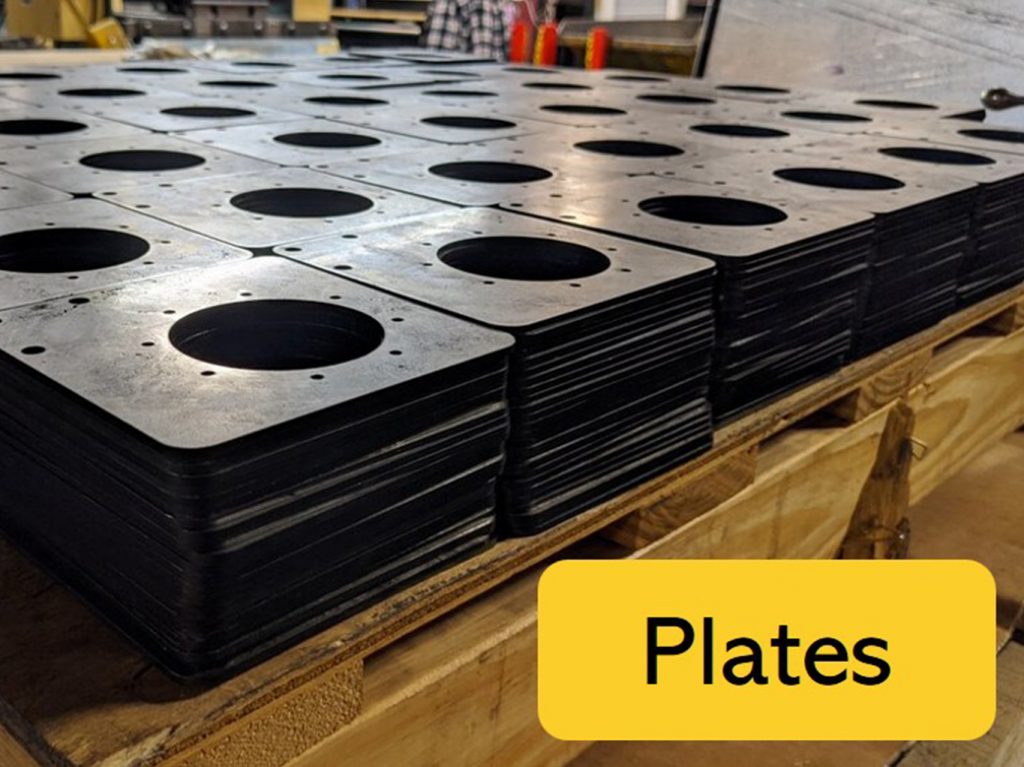

Material Selection & Cost Optimization

Choosing the right material is critical for both performance and cost efficiency.

At Fiesco Precision, our engineering team works with clients to evaluate design requirements, industry standards, and budget considerations to recommend the most effective material options.

This ensures durability, functionality, and cost control across every project.

Smarter Choices, Better Results

Through detailed analysis and supplier integration, we identify materials that balance strength, machinability, and price.

By optimizing both the selection and usage of raw materials, we help reduce waste, control production costs, and keep your projects within budget without compromising on quality.

Let’s Bring Your Vision to Life With High-Precision CNC Welding

Need clean, accurate cuts delivered fast? Fiesco Precision provides reliable laser cutting solutions designed to meet your exact specifications, timelines, and production requirements.