Electroless Nickel Plating

Electroless Nickel Plating Services

Uniform Protection. Zero Compromise.

Precision parts deserve a finish that’s even, corrosion-resistant, and dependable—especially when they feature complex shapes or tight tolerances. At Fiesco, our Electroless Nickel (EN) plating offers a superior surface treatment that ensures your components don’t just look good—they last longer, resist wear, and meet your industry’s most exacting standards.

Whether you’re in aerospace, automotive, medical, or electronics, our EN process delivers unbeatable performance, even in high-friction or high-heat applications.

What Is Electroless Nickel Plating?

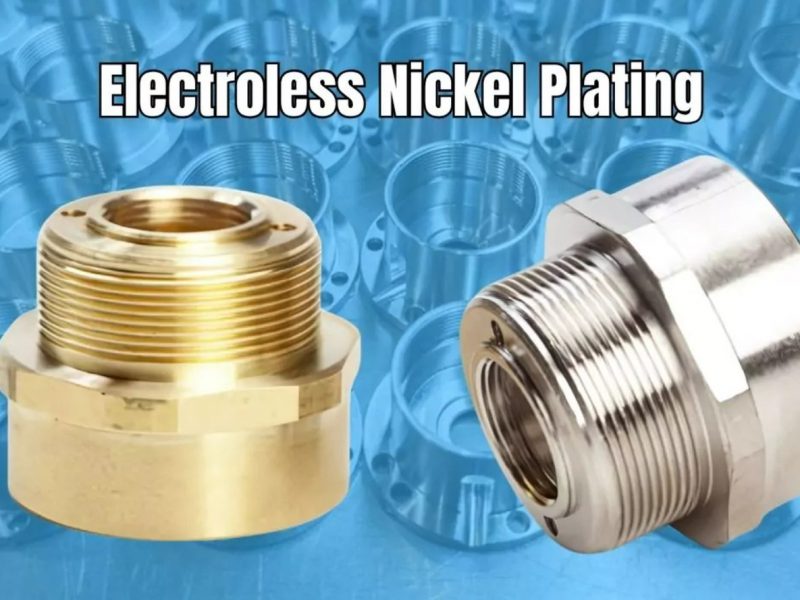

Unlike traditional electroplating, electroless nickel doesn’t require electricity to coat a surface. Instead, it uses a chemical reduction process to deposit a uniform layer of nickel-phosphorus alloy on a substrate.

This chemical method provides a consistent thickness, even on internal diameters, threads, sharp edges, and complex geometries—making it a go-to solution for high-precision applications.

Key Benefits of Electroless Nickel

Fiesco’s EN plating offers a range of functional and performance advantages:

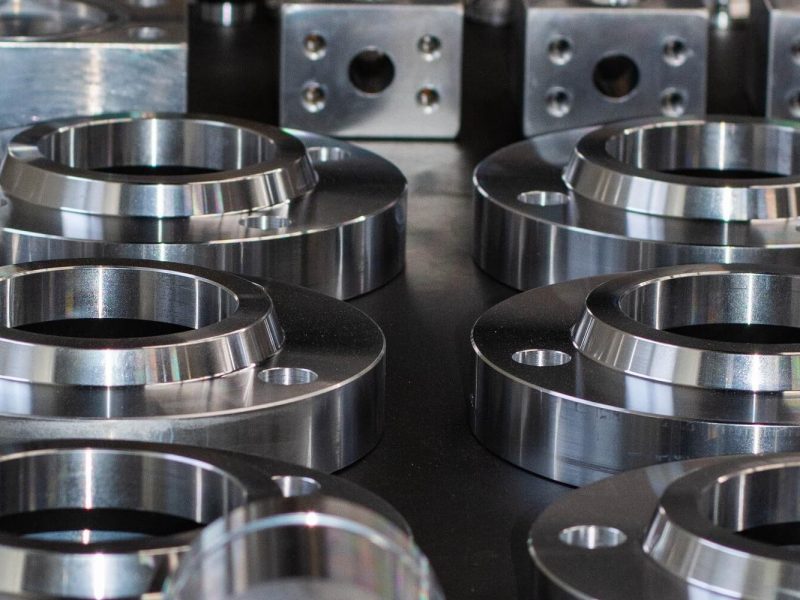

✅ Uniform thickness on all part surfaces

✅ Superior corrosion resistance, especially in harsh environments

✅ Hard, wear-resistant finish (up to 70+ Rc with heat treatment)

✅ Improved lubricity for sliding components

✅ Excellent solderability and electrical conductivity

✅ Compatible with aluminum, steel, copper, brass, and more

Where It Shines: Industry Applications

Electroless nickel is used in industries that demand reliability and protection at the microscopic level:

- Automotive – Pistons, transmission components, fuel injectors

- Aerospace – Flight instruments, actuators, housings

- Electronics – Connectors, circuit boards, contacts

- Medical Devices – Surgical tools, implants, housings

- Mold & Die – Injection molds, stamping dies, wear surfaces

From high-volume production to precision prototyping, Fiesco delivers EN finishes that withstand time, stress, and corrosion.

Get a Quote today

Get a fast, accurate quote tailored to your project needs.

Our Process: Chemical Precision

Fiesco’s plating line uses a strict, multi-stage process that ensures consistent quality and maximum performance:

- Surface Preparation

Thorough cleaning and etching to remove contaminants. - Activation & Catalyst Application

Prepares the metal surface for ideal chemical bonding. - Nickel Deposition

Immersion in a heated, pH-controlled solution containing nickel salts and reducing agents. - Optional Heat Treatment

Enhances hardness and wear resistance for critical components. - Inspection & Certification

Every part is checked for thickness, adhesion, and surface quality.

We tailor the process to your desired phosphorus content—low (2–5%), medium (6–9%), or high (10–13%)—depending on whether your priority is wear resistance, corrosion protection, or solderability.

Why Choose Fiesco?

- Engineered to spec – Perfect for critical tolerance applications

- In-house machining + finishing – One-stop fabrication and plating

- Fast turnaround – For urgent production or replacement needs

- Servicing Mexico and the U.S. – Especially Baja California, Querétaro, and border zones

- Certification available for aerospace, automotive, or electronics standards

At Fiesco, we combine technical expertise, full-service manufacturing, and unbeatable attention to detail to ensure your components exceed expectations.

Level-Up Your Surface Performance

When failure isn’t an option, and precision matters most, electroless nickel plating from Fiesco gives you a critical edge. Protect your parts, extend their life, and maintain performance—without compromising fit or function.

Contact us today to request a quote or material compatibility consultation.