Annealing Heat Treatment

Controlled Annealing Processes for Improved Ductility and Machinability

Make Your Metal More Ductile, Stress-Free, and Ready for Precision Work

Whether you’re forming complex parts or machining to tight tolerances, metal that’s too hard or brittle can crack, warp, or underperform. That’s where annealing makes the difference. At Fiesco Precision, we use precision-controlled annealing processes to give your materials the flexibility, softness, and structural consistency needed for downstream operations and long-term performance.

What Is Annealing?

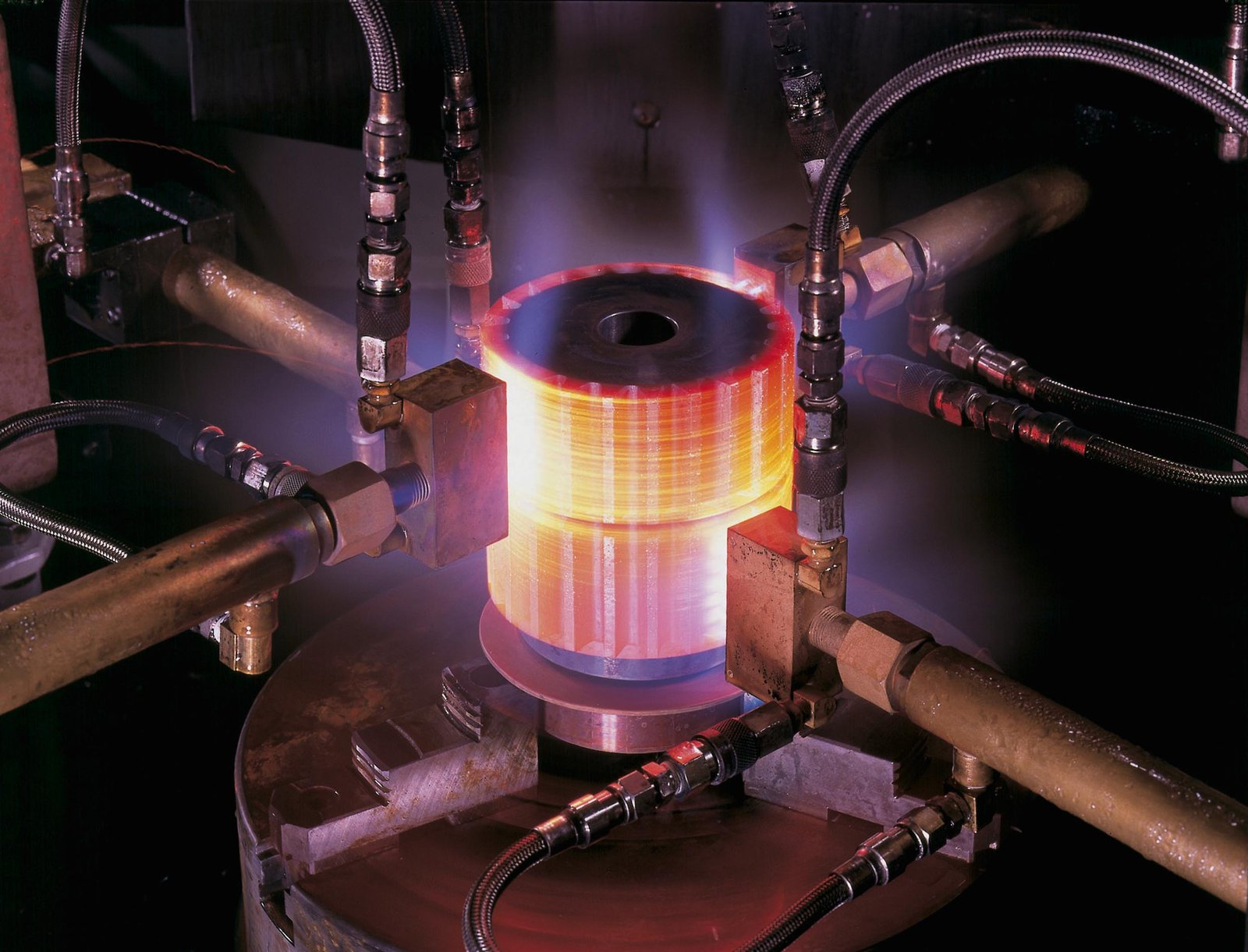

Annealing is a heat treatment process designed to soften metals, improve ductility, and relieve internal stress. It involves heating the metal to a specific temperature, maintaining it (soak time), and then cooling it slowly in a controlled environment.

This transformation alters the microstructure of the material—typically restoring it to its original grain structure or even improving it—making it easier to cut, bend, weld, or form.

Benefits of Annealing

✔️ Increased ductility and softness

✔️ Improved machinability

✔️ Stress-free material for forming and welding

✔️ Better dimensional stability

✔️ Grain refinement and improved structure

Where Annealing Adds Value

Annealing is commonly used across a variety of industries and components, including:

- Aerospace – Sheet metal, housings, and precision brackets

- Automotive – Exhaust systems, gears, and suspension parts

- Medical – Surgical tool blanks, supports, and stainless steel tubing

- Electronics – Copper and aluminum contacts or shielding

- Industrial Fabrication – Pipes, flanges, weldments, and custom tooling

Get a Quote today

Get a fast, accurate quote tailored to your project needs.

Fiesco Precision’s Annealing Process

We follow a meticulous, quality-driven approach tailored to your part’s material and geometry:

- Material Assessment

We analyze your material type, prior processing, and intended use. - Controlled Heating

The part is gradually heated to its target temperature, eliminating thermal shock. - Soak Time

We hold the part at the ideal temperature to allow full recrystallization. - Slow Furnace Cooling

The part cools slowly in the furnace to prevent distortion or new stress formation. - Final Review & Reporting

All parts are reviewed to confirm dimensional integrity and structural goals.

Why Annealing Matters in Manufacturing

Without annealing, materials like steel, aluminum, copper, and brass can become too hard, brittle, or distorted from prior operations such as:

- Cold working

- Casting

- Welding

- Rolling or forming

- Machining

Annealing resets the internal structure of the metal, unlocking the qualities that help you build better, faster, and with less rework.

Request Your Annealing Heat Treatment Quote Today

Let us know your material, required finish type, thickness, and quantity—our team will provide a tailored quote fast.

Use Softer, Smarter Metals

Annealing isn’t just about softening a part. It’s about unlocking its full potential—ensuring it responds predictably to forming, machining, or final use.

If you’re dealing with hard-to-cut metals, inconsistent forming results, or cracking issues, annealing is the step that brings everything back in line.

At Fiesco Precision, we help you produce metal components that perform reliably—because reliability starts at the core.

Let’s talk about your annealing needs and build better from the inside out.