Case Hardening Heat Treatment

High-PrecisionCase Hardening Services for Maximum Surface Strength

A Tough Core With a Rock-Hard Exterior

When you need parts that are impact-resistant on the inside but abrasion-resistant on the outside, case hardening is your go-to solution. It’s a dual-performance heat treatment that gives your components a wear-resistant shell and a ductile core, making them ideal for high-load, high-friction environments.

At Fiesco Precision, we perform case hardening with absolute control and repeatability—because your parts can’t afford to fail.

What Is Case Hardening?

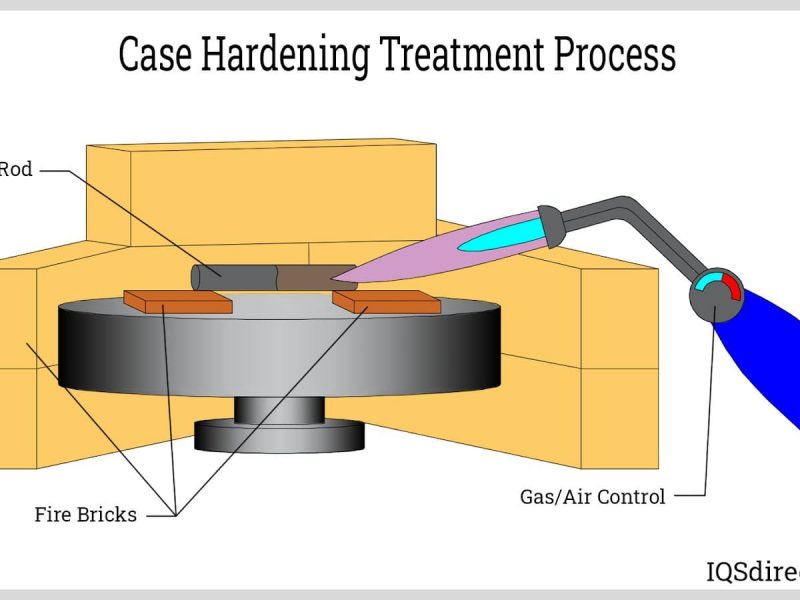

Case hardening is a thermochemical process that hardens only the outer layer (case) of a metal component while maintaining a tough, ductile core. It’s commonly used on low-carbon steels that would otherwise be too soft to handle friction and wear.

We offer various types of case hardening, including:

- Carburizing

- Carbonitriding

- Nitriding (as a subtype)

Each method is selected based on part geometry, application, and desired hardness depth.

Key Benefits of Case Hardening

- Superior wear resistance on the surface

- Strong, ductile interior to resist shock

- Longer component lifespan

- Reduced need for lubrication or replacement

- Improved fatigue strength under dynamic loads

Ideal Applications

Case hardening is perfect for components exposed to sliding contact, shock loads, and repeated motion, such as:

- Gear teeth

- Shafts

- Sprockets

- Pins and bushings

- Clutch parts

- Cam followers

Get a Quote today

Get a fast, accurate quote tailored to your project needs.

Why Choose Fiesco for Case Hardening?

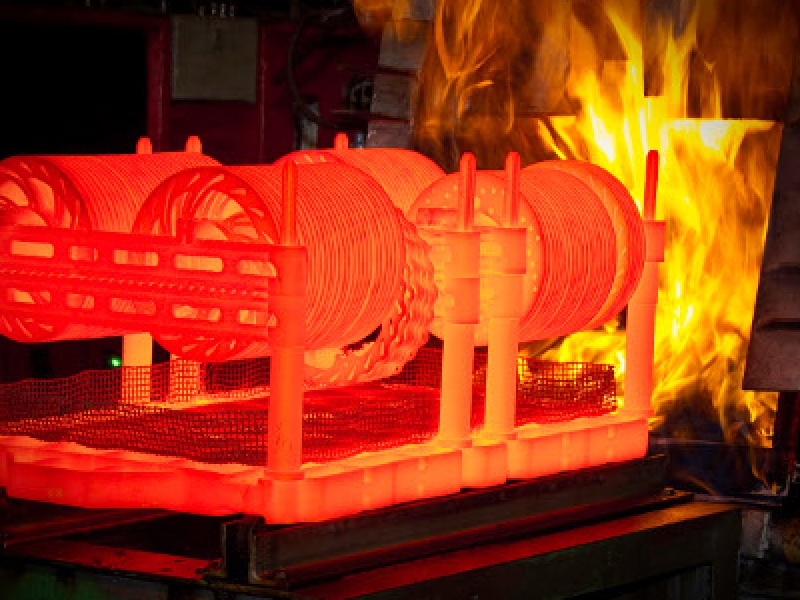

When surface and core performance must work together, poor treatment isn’t an option. Our state-of-the-art furnaces, advanced controls, and years of metallurgical expertise ensure you get the hardness you need without sacrificing internal strength or dimensional accuracy.

We partner with clients in:

- Automotive manufacturing

- Aerospace

- Agriculture and off-road

- Industrial machinery

Tooling and molds

How It Works at Fiesco

- Part Cleaning and Prep – We clean, degrease, and inspect each component before processing.

- Carburizing/Carbonitriding Stage – Parts are heated in a carbon-rich atmosphere to infuse the outer layer.

- Quenching and Tempering – To lock in hardness while managing internal stress.

- Final Inspection – We measure case depth, hardness profile, and microstructure to meet spec.

Request Your Case Hardening Quote Today

Let us know your material, required finish type, thickness, and quantity—our team will provide a tailored quote fast.

Surface Strength Meets Inner Durability

Imagine a part that absorbs shocks like a sponge—but resists wear like a diamond. That’s the power of case hardening, and it’s how Fiesco Precision helps your machinery run longer, safer, and more reliably.

Reach out today to get a quote or discover whether case hardening is the right choice for your next manufacturing project.