Carburizing Heat Treatment

Carburizing Services for Increased Surface Hardness and Core Toughness

Maximize Wear Resistance Without Sacrificing Toughness

If your parts need to last longer under constant friction, carburizing is the answer. This process creates a hard, wear-resistant surface on steel parts while preserving a strong and ductile core—giving you the best of both worlds.

At Fiesco Precision, we use precise temperature control, atmosphere regulation, and quenching techniques to deliver repeatable, high-performance carburized components for demanding industries.

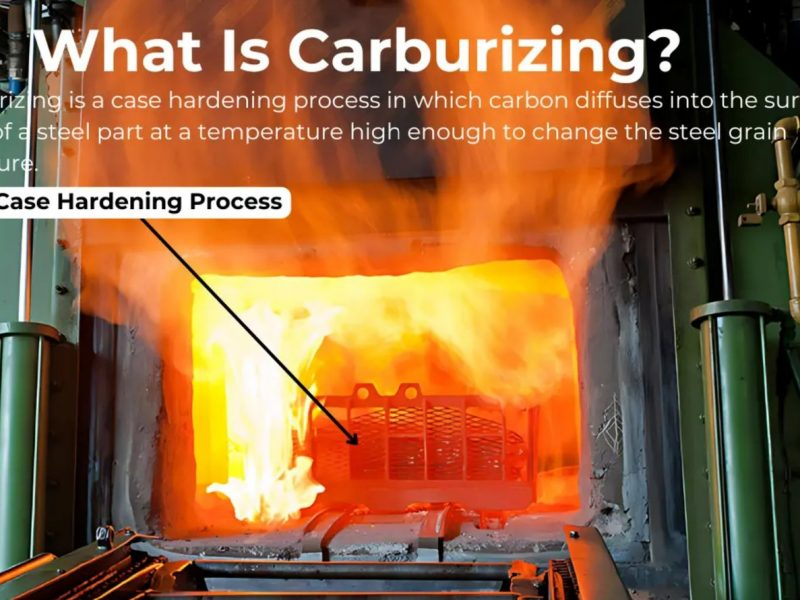

What Is Carburizing?

Carburizing is a thermochemical heat treatment that introduces carbon into the surface layer of a steel part at elevated temperatures. After the carbon has diffused into the material, the part is rapidly quenched to harden the outer shell, while the core remains tough and impact-resistant.

The result? A component that resists wear, fatigue, and failure in high-load, high-speed environments.

Carburizing Benefits

- Extreme surface hardness (HRC 58–64)

- High resistance to abrasion and pitting

- Improved fatigue life

- Ideal for gears, cams, and moving parts

- Reduced maintenance and downtime

Best Applications for Carburizing

Carburizing is ideal for low-carbon or alloy steel components exposed to friction and sliding contact, such as:

- Gears and pinions

- Sprockets and shafts

- Bearings and races

- Wear plates

- Crankshafts and camshafts

Whether you’re in automotive, aerospace, tooling, or heavy machinery, carburizing is a game-changer for part longevit

Get a Quote today

Get a fast, accurate quote tailored to your project needs.

Why Choose Fiesco for Carburizing?

Carburizing requires exact control of case depth, carbon potential, and quenching methods—any variation can lead to cracks, distortion, or inconsistent hardness.

At Fiesco, our carburizing processes are backed by:

- State-of-the-art furnaces with digital control systems

- Precision case depth targeting (from 0.010″ to 0.125″+)

- Post-treatment inspection using hardness profiling and microstructural analysis

Zero-compromise approach to part cleanliness and preparation

How Our Process Works

- Surface Prep – Parts are degreased, cleaned, and inspected before treatment.

- Carburization – Components are exposed to a carbon-rich gas atmosphere at high temperatures (1600–1700°F).

- Diffusion Stage – The carbon atoms diffuse into the steel to form a controlled case depth.

- Quenching and Tempering – Rapid quenching locks in surface hardness, while tempering enhances stability and toughness.

Inspection – Every batch undergoes surface hardness testing and microstructure validation.

Request Your Carburizing Heat Treatment Quote Today

Let us know your material, required finish type, thickness, and quantity—our team will provide a tailored quote fast.

Built to Last — Down to the Core

Carburized parts deliver performance where it matters most: on the surface for durability and in the core for shock resistance. At Fiesco Precision, we deliver carburizing services engineered for consistency, quality, and precision, batch after batch.

Contact our team to explore how carburizing can improve your component lifespan and reduce your total cost of ownership.