CNC Machining Center

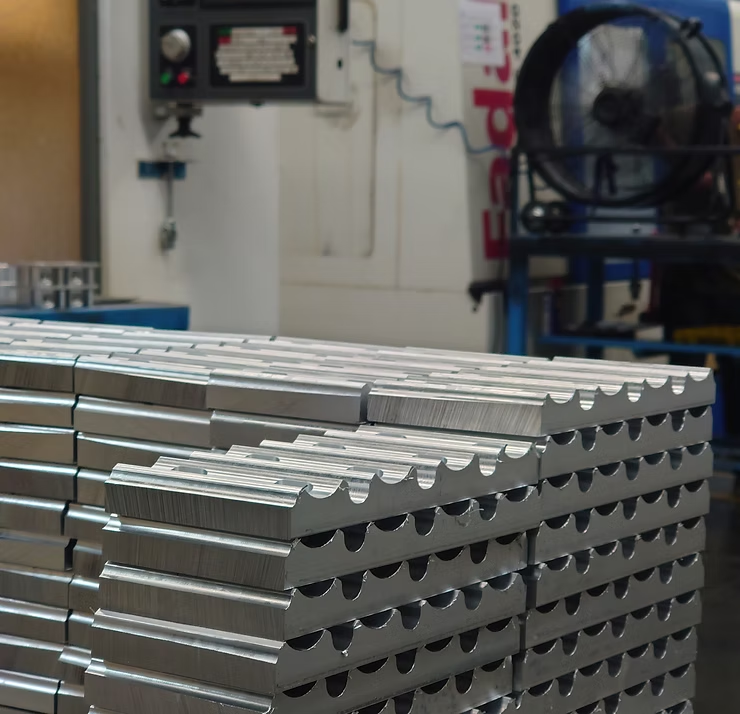

CNC Machining– Precision from Prototype to Production

High Quality CNC Machining services

Fiesco Precision delivers high-quality CNC machining with accuracy, speed, and cost efficiency. From prototypes to large-scale production, we ensure your parts are made right the first time.

High-Precision CNC Services for California Manufacturers

Our CNC machining services are tailored for industries requiring complex, accurate, and repeatable parts. With our experienced engineering team and top-tier equipment, we offer solutions that go from design to large-batch production with consistent quality.

Advantages of CNC Machining

Our CNC machining cutting process ensures maximum raw material utilization and optimized production times.

Usage of programmed numerical codes, with high precision, bring consistent and accurate results for every order.

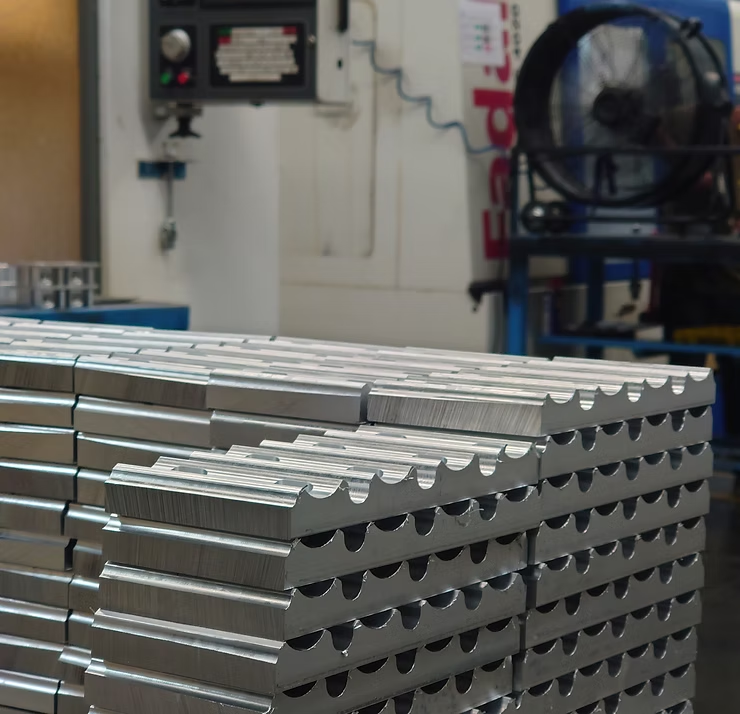

Capacity & Material Capabilities

Plates of

Min 16“ x 20”

Max 20” x 50”

Our CNC capabilities include:

- MILL – Precision milling for parts with tight tolerances

- LATHE – High-speed turning services for cylindrical components

- LARGE PARTS – Machining of oversized components with strict precision

- MARKING – Part engraving and traceability markings

- LABELING – Industrial labeling integrated into the production line

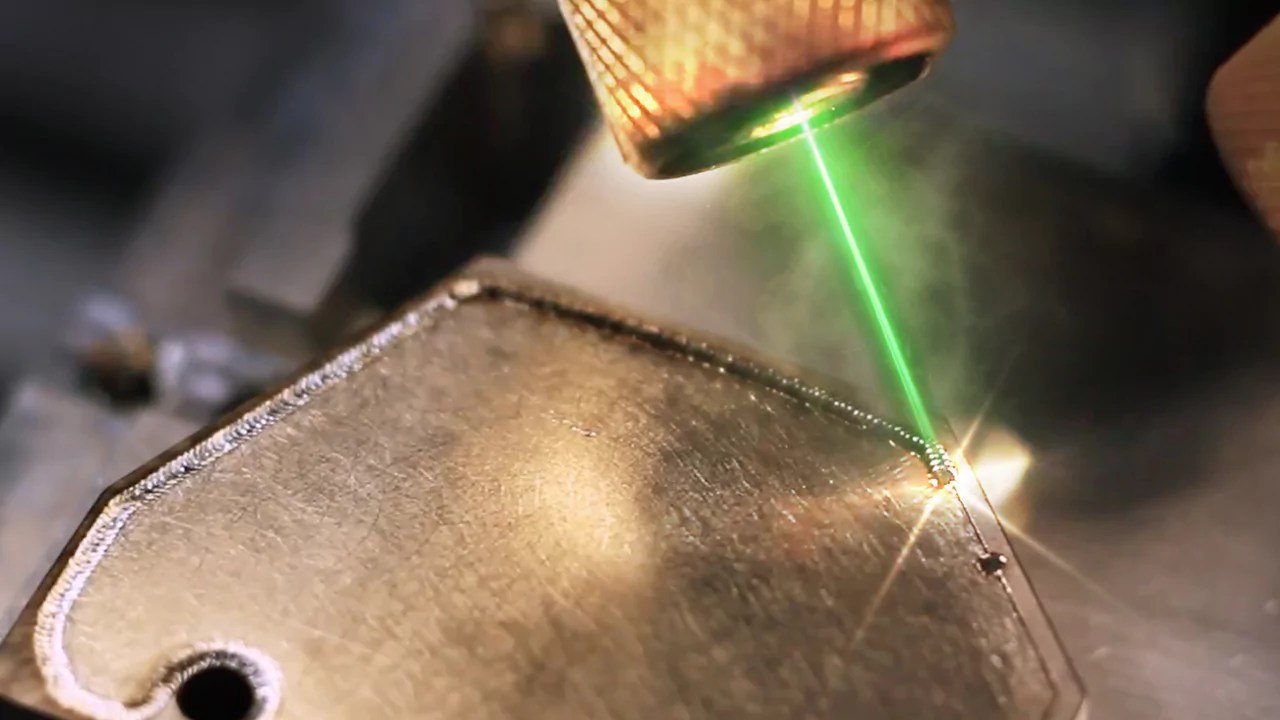

- WELDING – High-quality welds for assembly and fabrication

- ASSEMBLY – Final mechanical assembly to streamline production

We proudly serve industries throughout Southern California, including San Diego, Riverside, Los Angeles, and surrounding areas.

Quality Control & Supply Chain Management

At Fiesco Precision, quality and reliability are built into every stage of the supply chain. Our engineering team ensures seamless coordination between suppliers and production with a proactive, standardized approach:

✅ Supplier training and alignment with strict management systems for consistent and ON-TIME deliveries.

✅ Incoming inspections to verify raw materials before starting production.

✅ In-process quality checks that detect and correct issues early.

✅ Final product release only when all customer specifications are fully met.

✅ Streamlined communication that minimizes errors and delays thru whole production process.

By integrating supplier management with robust quality control, we reduce risk, eliminate delays, and guarantee precision parts delivered on time

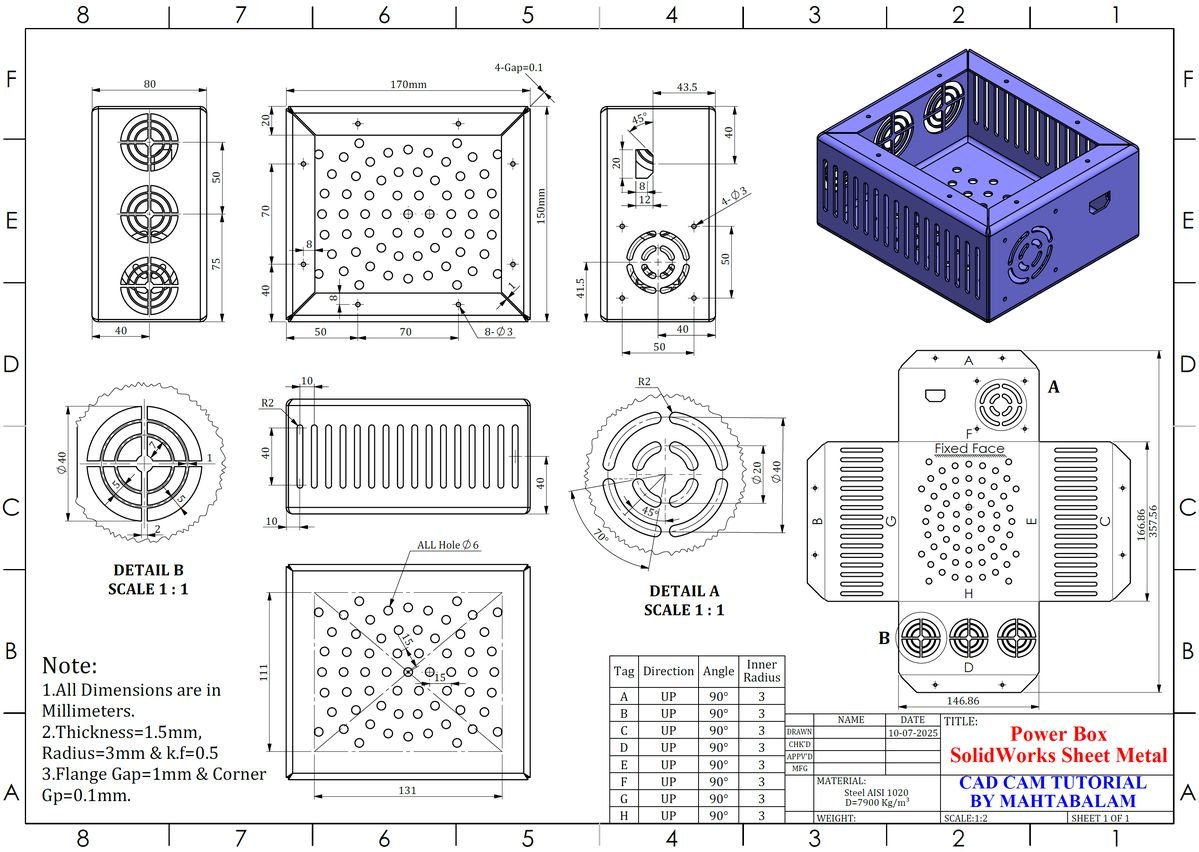

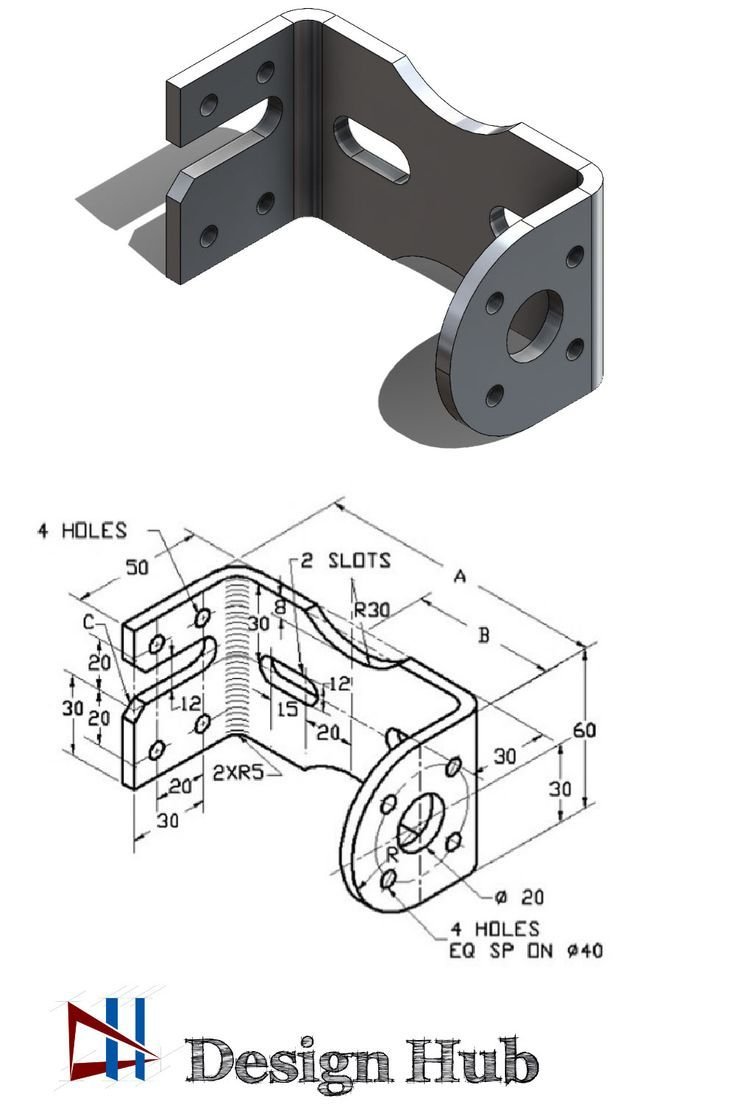

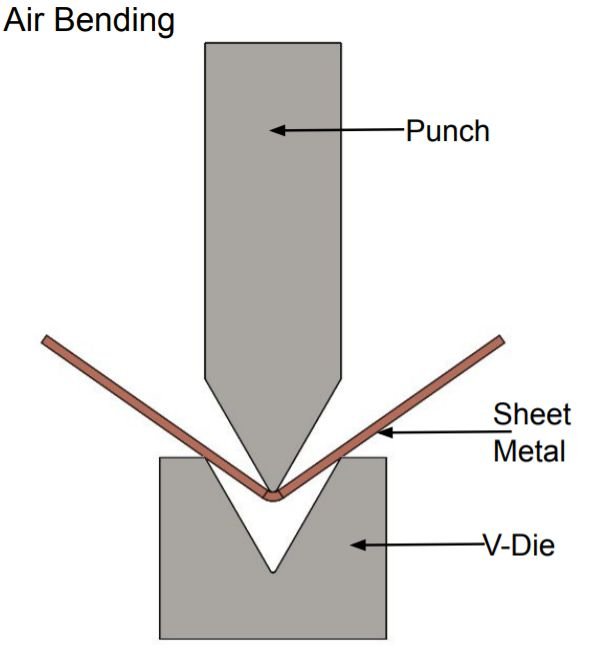

Sheet Metal Fabrication – Flexible & Scalable Solutions

Full-Service Sheet Metal Work From Baja California to the U.S.

Our sheet metal fabrication division handles both simple and complex components using cutting-edge machinery. From prototyping to full production runs, we meet the highest quality standards for demanding industries like automotive, aerospace, and medical.

Sheet Metal Services Offered:

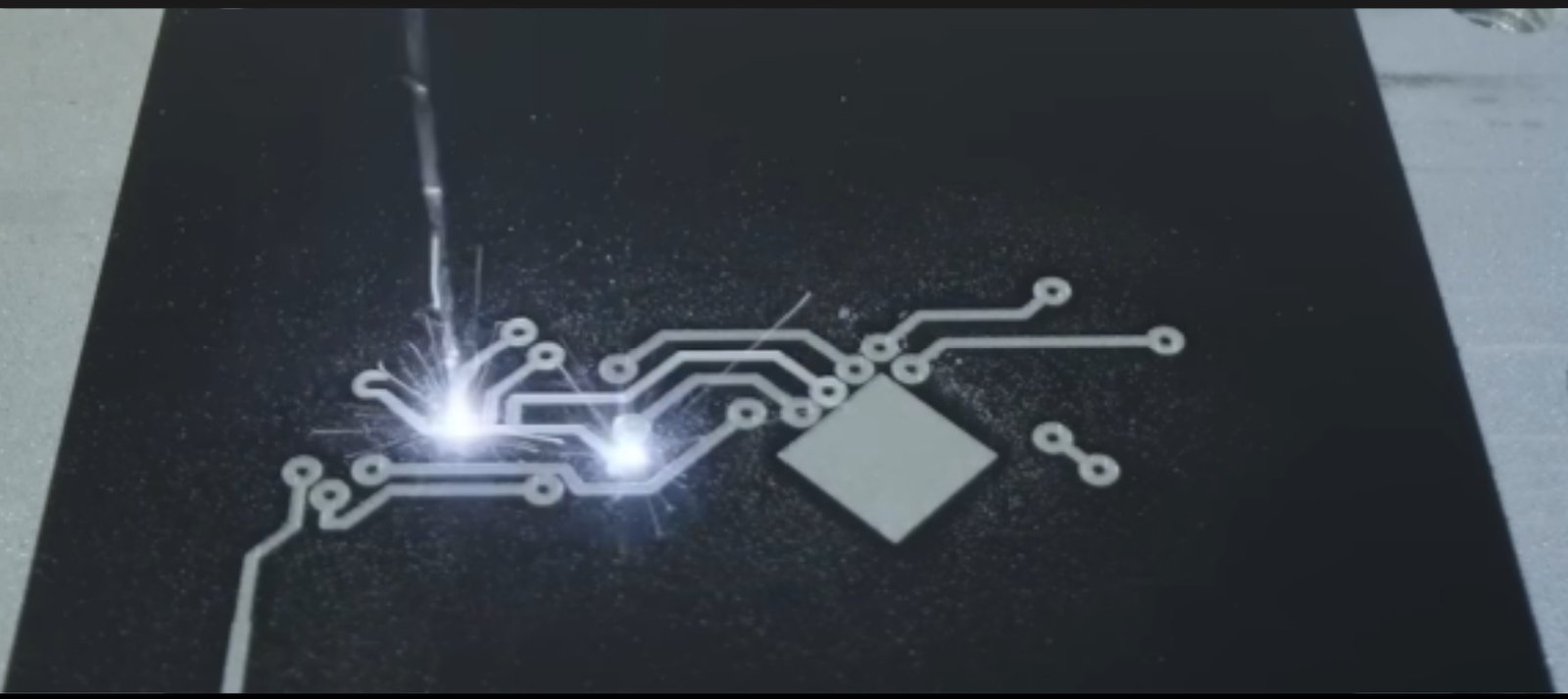

- LASER CUT – Clean, precise laser cutting for complex shapes

- BENDING – Custom bends with consistent accuracy

- MARKING – Durable markings for inventory and quality control

- LABELING – Laser or ink labeling on metal surfaces

- WELDING – TIG/MIG welding with aesthetic and structural strength

- ASSEMBLY – Sheet metal parts pre-assembled for easy integration

We ship quickly to clients across California and maintain seamless logistics from Tecate, B.C., thanks to our proximity to the U.S. border.

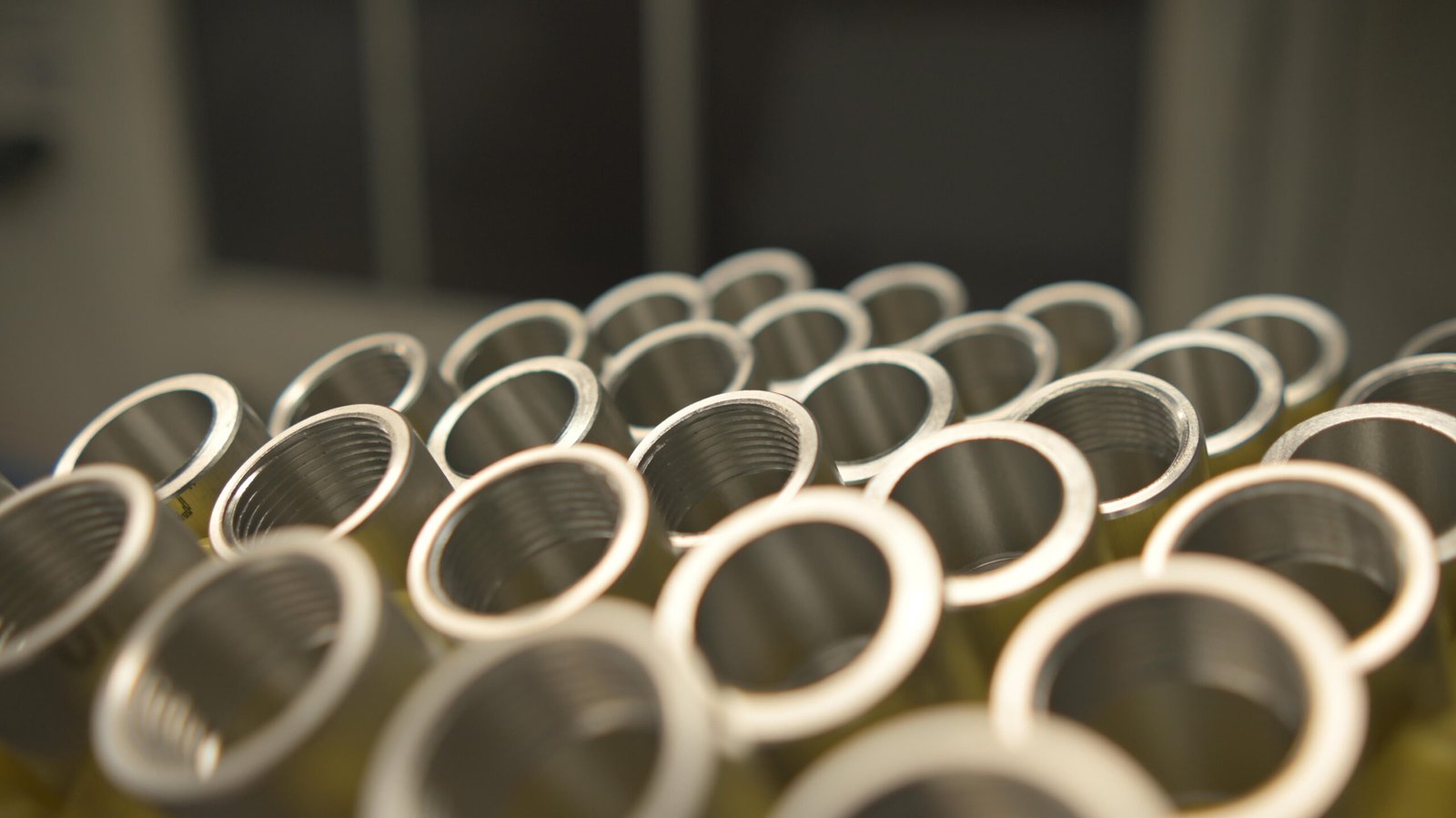

Explore Our Specialized CNC Machining Equipment

At Fiesco Precision, we operate a wide range of CNC machining centers equipped to handle complex projects with accuracy and speed. Our advanced machinery allows us to produce prototypes, custom parts, and high-volume orders while maintaining consistent precision and reliability.

With this technology, we can meet diverse industry requirements and deliver parts on time, every time.

Higher precision

Technology integration will reduce cycle times

Fiesco is a safety working place

Optimized usage of raw material

Fiesco Precision

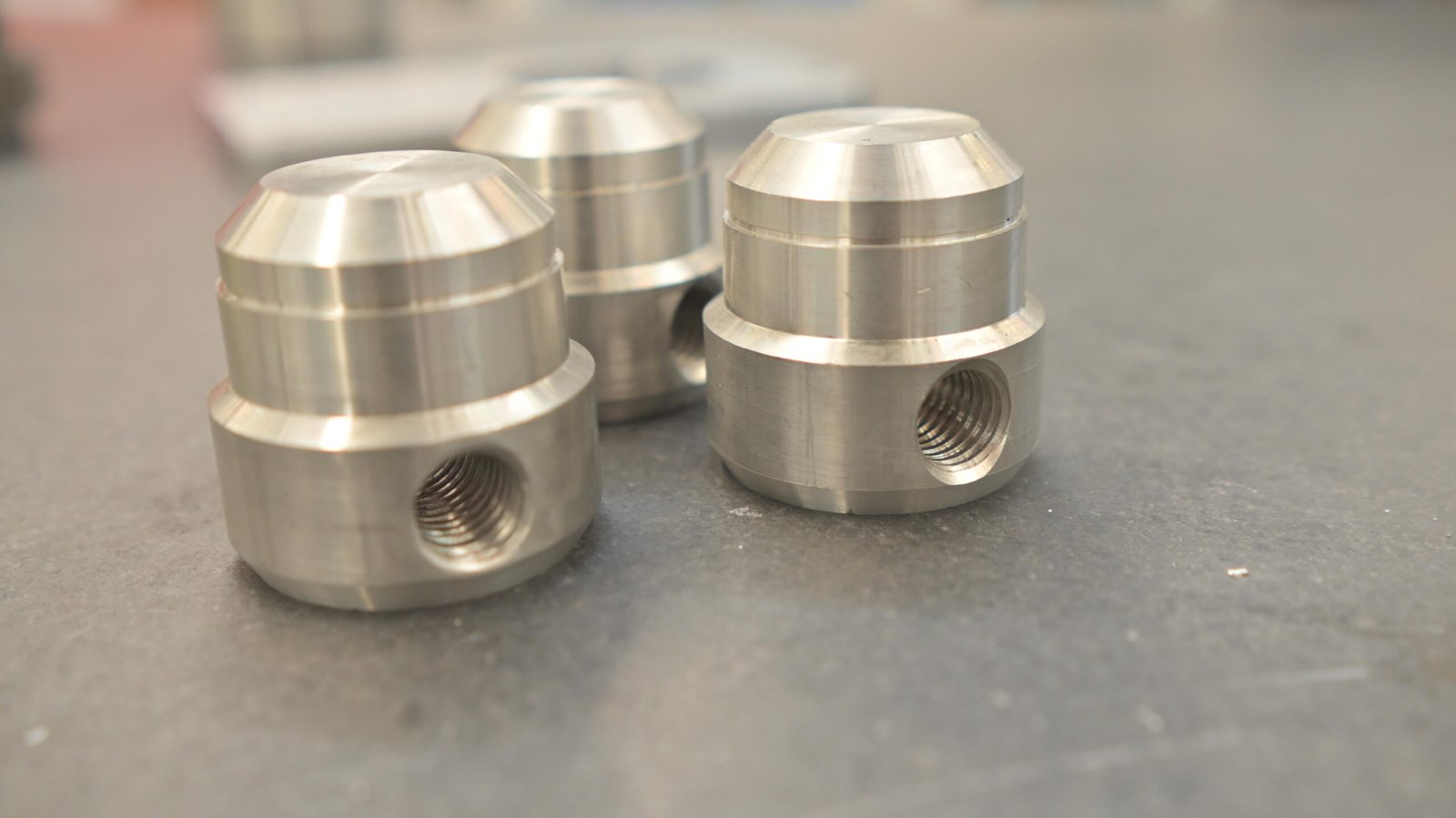

Material Selection & Cost Optimization

Choosing the right material is critical for both performance and cost efficiency.

At Fiesco Precision, our engineering team works with clients to evaluate design requirements, industry standards, and budget considerations to recommend the most effective material options.

This ensures durability, functionality, and cost control across every project.

*

Smarter Choices, Better Results

Through detailed analysis and supplier integration, we identify materials that balance strength, machinability, and price.

By optimizing both the selection and usage of raw materials, we help reduce waste, control production costs, and keep your projects within budget without compromising on quality.

Our CNC Machining Inventory

6 FADAL 4020

2 FADAL 2216

4 FADAL 3016

2 FADAL 2016

1 FADAL 5020

Other Integrated Services

Let’s bring your vision to life with high-precision CNC Machining.

Need precision parts, fast and reliable? Fiesco Precision delivers on-time CNC machining solutions tailored to your specs and budget.