Medical Industry CNC Services in California

Advanced CNC Manufacturing for the Medical Industry

High-precision machining, fabrication, and component production for medical manufacturing and processing systems.

Supporting Medical Manufacturing in California for Over 20 Years

Over the past 20 years, FIESCO has supported medical manufacturing across California, working on projects ranging from surgical models and functional prototypes to full production support.

Our capabilities include precision machining, laser cutting, sub-assembly, and the integration of mechanical, pneumatic, and hydraulic systems, as well as specialized components such as belts, rollers, sprockets, conveyors, partitions, and custom assemblies.

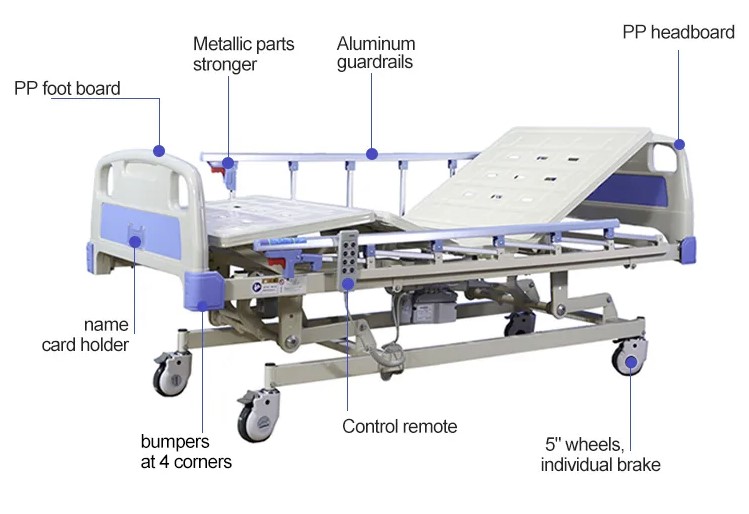

For finished medical products, we supply components for short-, medium-, and long-volume production runs, utilizing CNC machining, laser cutting, welding, sheet metal fabrication, and a wide range of finishing processes to meet medical industry requirements.

Throughout our work with California-based medical manufacturers, we have developed solutions using a broad range of medical-grade materials, including stainless steels in multiple grades, aluminum, engineering plastics, tool steels, and machinery-grade steels—ensuring precision, durability, and compliance at every stage of production.

Quality is at the heart of everything we do at Fiesco Precision

Components & Equipment for Medical Production

We also coordinate a variety of finishes with our internal and external suppliers according to our clients’ needs, including anodizing, powder coating, nickel plating, heat treatment, and more.

We are an expert engineering team that provides on-site technical support to our clients, working together to analyze areas of opportunity and improve processes or products to achieve the best profitability.

Production Capabilities for Finished Medical Components

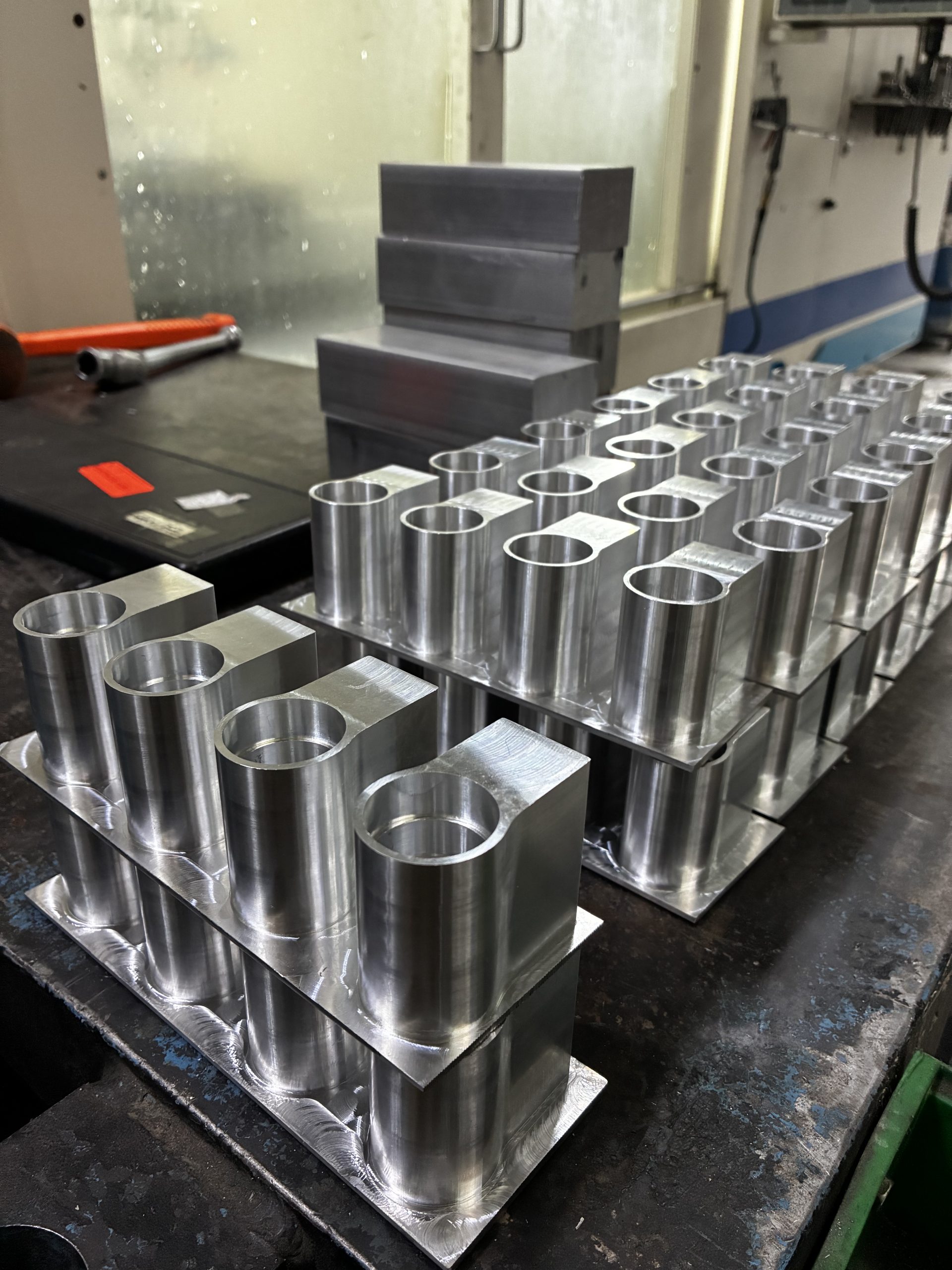

Fiesco supports small, medium, and large production runs, delivering consistency, cleanliness, and dimensional precision. Our capabilities allow us to produce parts with tight tolerances and reliable repeatability across high-volume production.

Applications include:

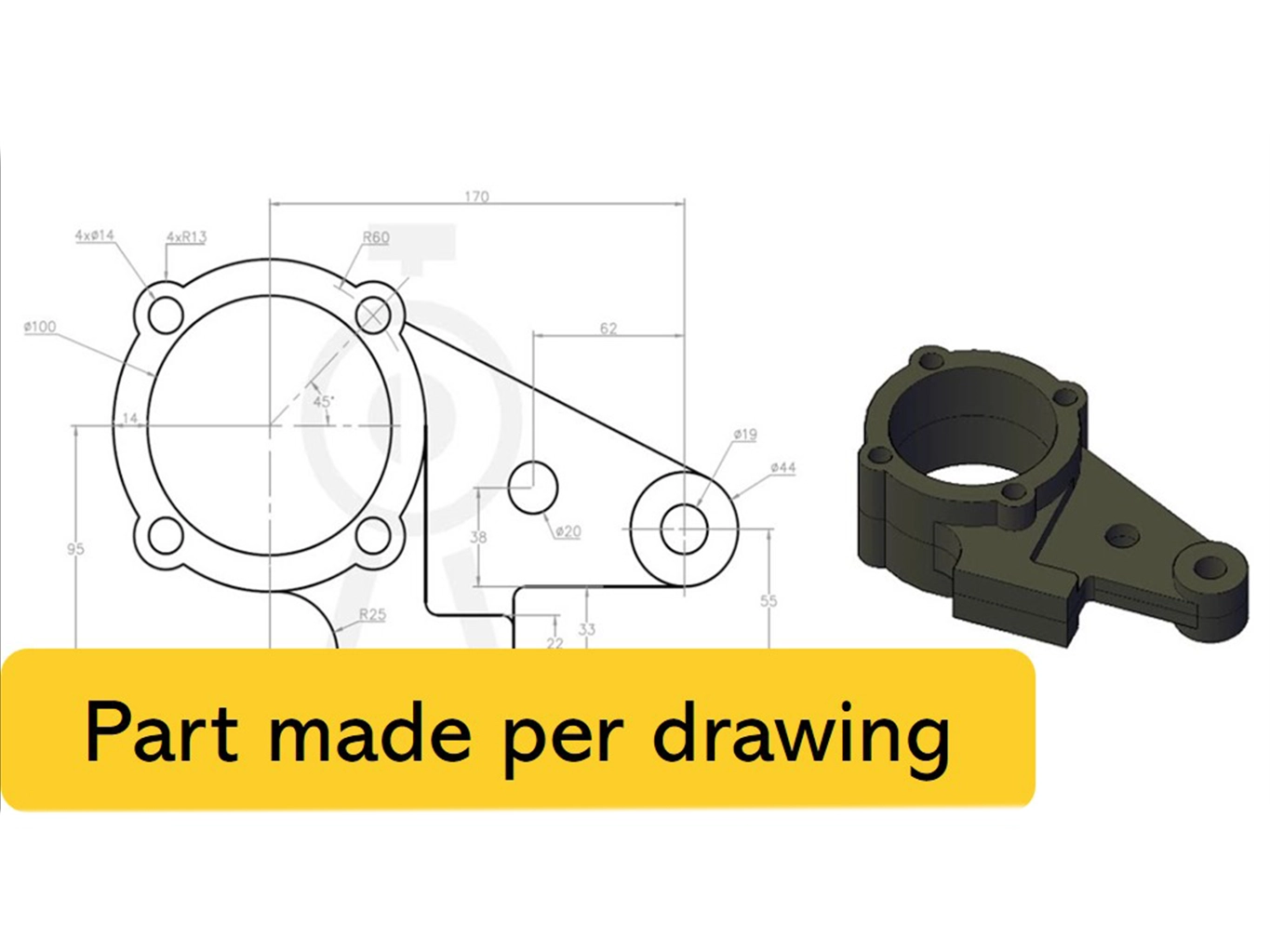

CNC machining for complex medical components

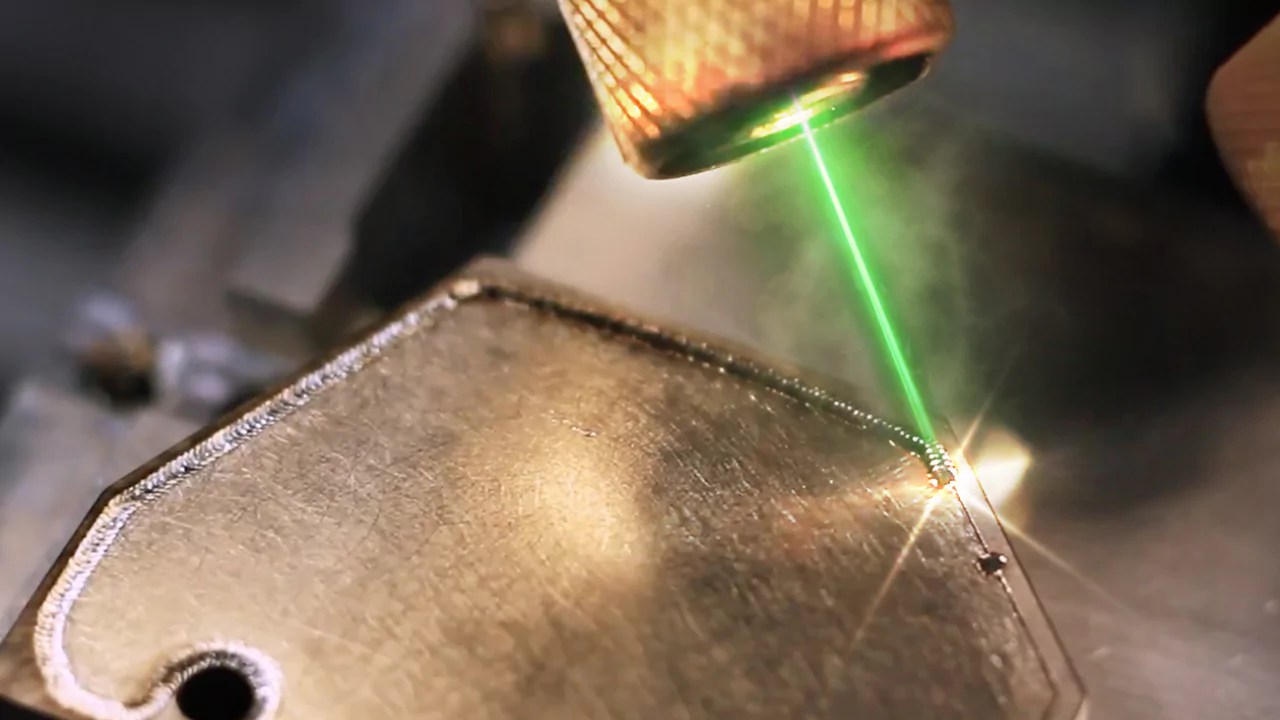

Laser cutting for high-accuracy profiles

Industrial welding for mechanical and stainless-steel assemblies

Subassemblies ready for integration into medical production systems

Medical Customized parts

Materials & Finishes for Medical Grade Components

We work with materials commonly used in medical environments, including various grades of stainless steel, aluminum, engineering plastics, tool steels, and machinery-grade steels. These materials ensure strength, corrosion resistance, and sanitary performance.

We also offer specialized finishes that meet industry requirements, including anodizing, plating, powder coating, and heat treatment.

Engineering Support for Medical Applications

Our engineering team provides continuous technical support to help manufacturers optimize equipment, processes, and product performance.

We collaborate closely with clients to identify opportunities for improvement and ensure each component meets strict quality and functional standards.

Through this partnership approach, we help medical manufacturers enhance reliability, efficiency, and long-term performance.

Reliable Precision CNC Manufacturing in California for Medical Industry

Get high-quality CNC machining, fabrication, and component production designed for medical-grade performance and reliability.