The mechanical industry relies on components that must perform under constant stress, motion, and load. Even minor dimensional inaccuracies can lead to misalignment, vibration, accelerated wear, or complete system failure. This is why precision CNC machining plays a critical role in modern mechanical manufacturing.

At FIESCO, precision CNC machining is combined with engineering expertise, tooling, and finishing services to support manufacturers facing the most demanding mechanical challenges.

Key Manufacturing Challenges in the Mechanical Industry

Mechanical systems are complex assemblies where performance depends on accuracy, consistency, and durability. Some of the most common challenges include:

1. Tight Tolerances and Fit Issues

Mechanical components such as shafts, housings, brackets, and gears must fit together precisely. Poor tolerance control can cause tolerance stack-up, leading to misalignment and premature failure.

2. Wear, Friction, and Fatigue

Mechanical parts are exposed to continuous motion and load. Inadequate surface finish or dimensional inconsistency increases friction, accelerating wear and reducing component lifespan.

3. Repeatability in Production

Producing the same mechanical component repeatedly with consistent accuracy is essential for scalable manufacturing. Manual or low-precision processes often fail to deliver this consistency.

4. Complex Geometries

Modern mechanical designs increasingly involve complex shapes that are difficult to manufacture using conventional machining methods.

How Precision CNC Machining Addresses These Challenges

High-Accuracy Machining

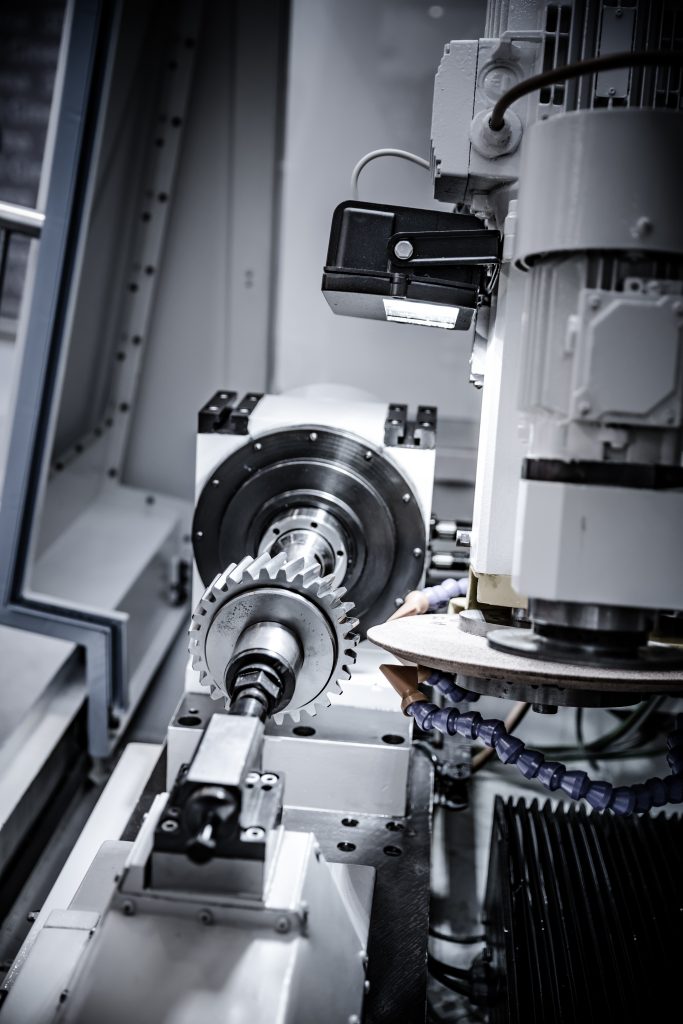

CNC machining enables tight tolerances and dimensional control that mechanical assemblies require. Multi-axis CNC equipment allows complex geometries to be machined accurately and repeatedly.

Improved Surface Finish

Precision CNC machining, combined with finishing processes, reduces surface roughness, lowering friction and improving component performance in moving assemblies.

Consistent Repeatability

Once a CNC program is validated, parts can be reproduced with minimal variation, ensuring consistency across production runs.

Design for Manufacturability Support

FIESCO provides engineering support to optimize mechanical part designs for CNC manufacturing, reducing cost and improving performance.

Learn more about FIESCO’s mechanical capabilities:

https://fiesco.mx/industries/mechanical-industry/

Applications of CNC Machining in the Mechanical Industry

Precision CNC machining supports a wide range of mechanical applications, including:

- Gears and gear housings

- Shafts and couplings

- Structural brackets and supports

- Tooling and fixtures

- Mechanical assemblies for industrial equipment

These components are commonly used across industries such as automotive, construction, and U.S. contractor projects, where reliability is critical.

The Role of Finishing in Mechanical CNC Components

Precision machining alone is not always enough. Finishing services such as grinding, heat treatment, and coating enhance durability and performance.

Benefits of integrated finishing services include:

- Increased wear resistance

- Improved corrosion protection

- Enhanced surface smoothness

- Longer component lifespan

FIESCO integrates machining and finishing to deliver ready-to-use mechanical components.

Why Mechanical Manufacturers Choose FIESCO

- Precision CNC machining with tight tolerances

- Engineering support for mechanical design optimization

- Capability for small, medium, and large components

- Consistent quality and repeatability

- Turnkey manufacturing solutions

Precision CNC machining is essential for overcoming the challenges faced by the mechanical industry. From tolerance control to repeatability and durability, CNC technology enables manufacturers to produce high-performance mechanical components with confidence.

FIESCO delivers precision CNC machining solutions tailored to mechanical manufacturing needs, backed by engineering expertise and integrated finishing services.

Request your custom CNC quote today