Sheet Metal Fabrication

Sheet Metal CNC Solutions

Advanced Sheet Metal CNC Manufacturing Solutions

At FIESCO, we bridge the gap between complex forming and CNC precision. Our integrated approach ensures that every sheet metal component begins with CNC-accurate cutting and bending to guarantee a perfect fit-up during final assembly, reducing material fatigue and ensuring the dimensional integrity of even the most intricate enclosures and structures.

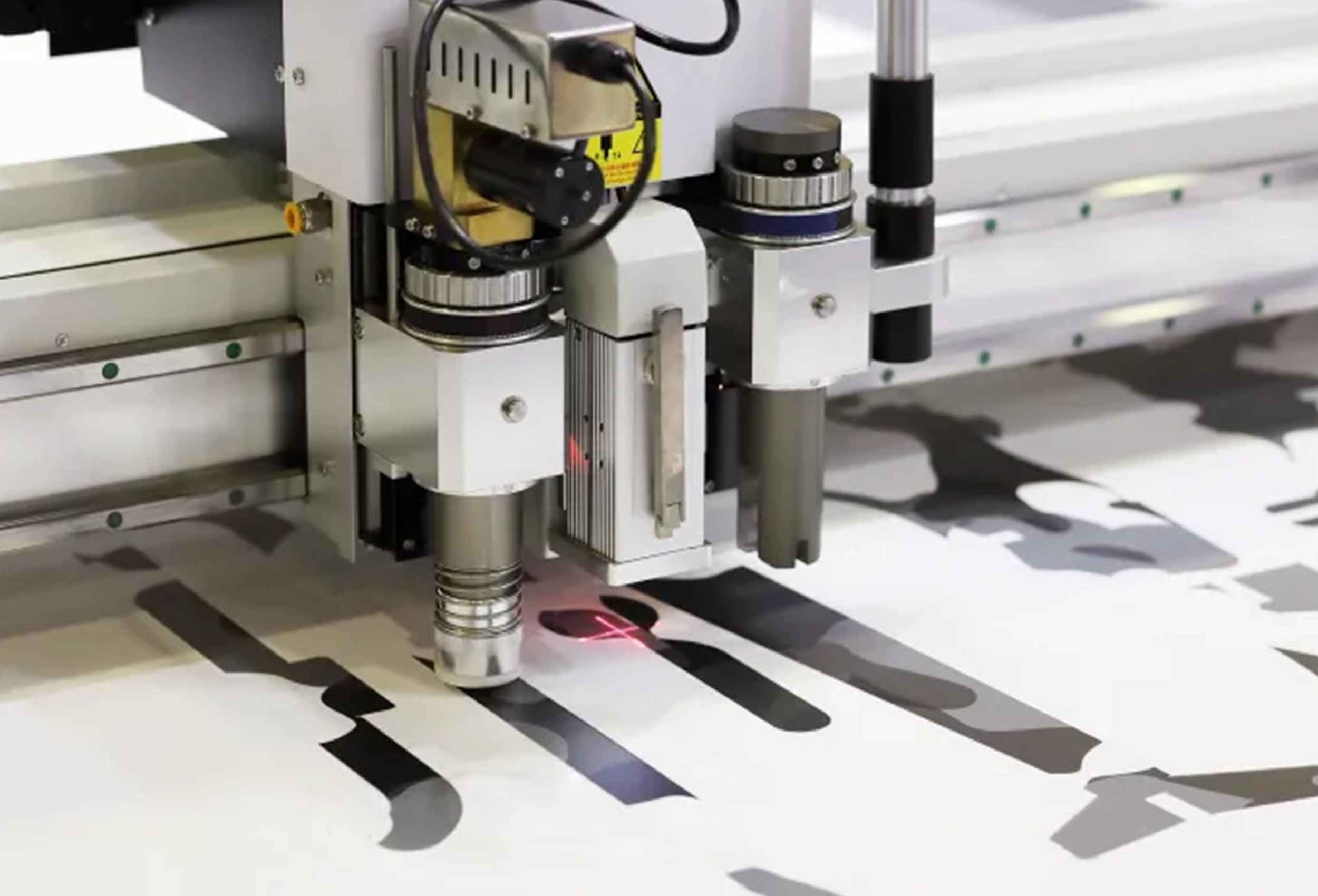

Shear Cutting Services

We provide straight, fast, and precise sheet metal cutting tailored to your specifications, ideal for medium- and high-volume production.

Our team specializes in accelerated lead times to keep your projects moving, always meeting your technical requirements with accuracy and consistency.

Delivery in as Fast as 2 Days

Prototypes and Small Batch Runs

- Ultra-fast response times

- Ideal for samples and short runs

- Efficient, cost-effective production

Standard Production

Consistent, Scheduled Deliveries

- On-time delivery compliance

- Delivery schedule tailored to your needs

- Ideal for medium and high volumes

plasma cutting services

At Fiesco, we provide powerful and versatile plasma cutting for electrically conductive metals of medium and heavy thickness.

We deliver accurate, fast, and cost-efficient cuts, adapting to the needs of a wide range of industrial sectors. Additionally, we integrate CAD/CAM software to achieve maximum precision and efficiency.

Delivery in as Fast as 2 Days

- Prototypes and short production runs

- Agile response and efficient production

- Ideal for thicker material parts

Standard Production

- Scheduled delivery programs

- Continuous and flexible production

- Medium to high-volume capacity

waterjet cutting services

We provide high-precision waterjet cutting for virtually any material using an ultra-high-pressure water stream, with or without abrasive.

This process prevents deformation and internal stresses, delivering detailed cuts in heat-sensitive and thick materials, while adapting efficiently to a wide range of industrial requirements.

Delivery in as Fast as 3 Days

- Prototypes and small batches

- High-precision, heat-free cutting

- Ideal for thick and sensitive materials

Standard Production

- Scheduled delivery programs

- Continuous and flexible production

- Lead times tailored to your needs

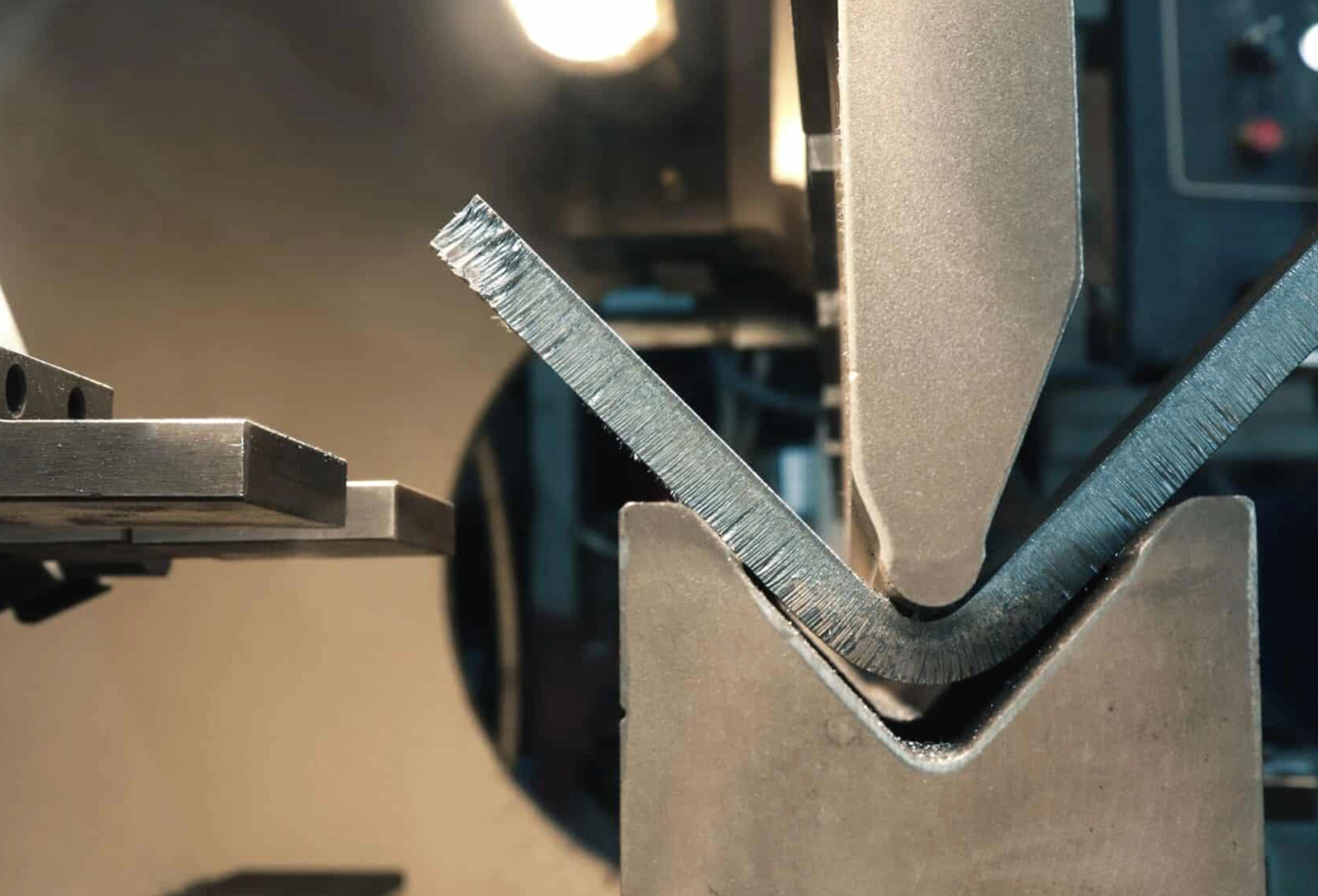

conventional folding services

We bend all types of steel and aluminum for both simple and complex shapes. Our engineering team provides expert support and customized solutions to ensure your projects meet the required specifications, delivering high-quality formed parts every time.

Delivery in as Fast as 4 Days

- Prototypes and small batch runs

- Agile and versatile production

- Fast and reliable delivery

Standard Production

- Scheduled delivery programs

- Consistent and flexible lead times

- Ideal for higher production volumes

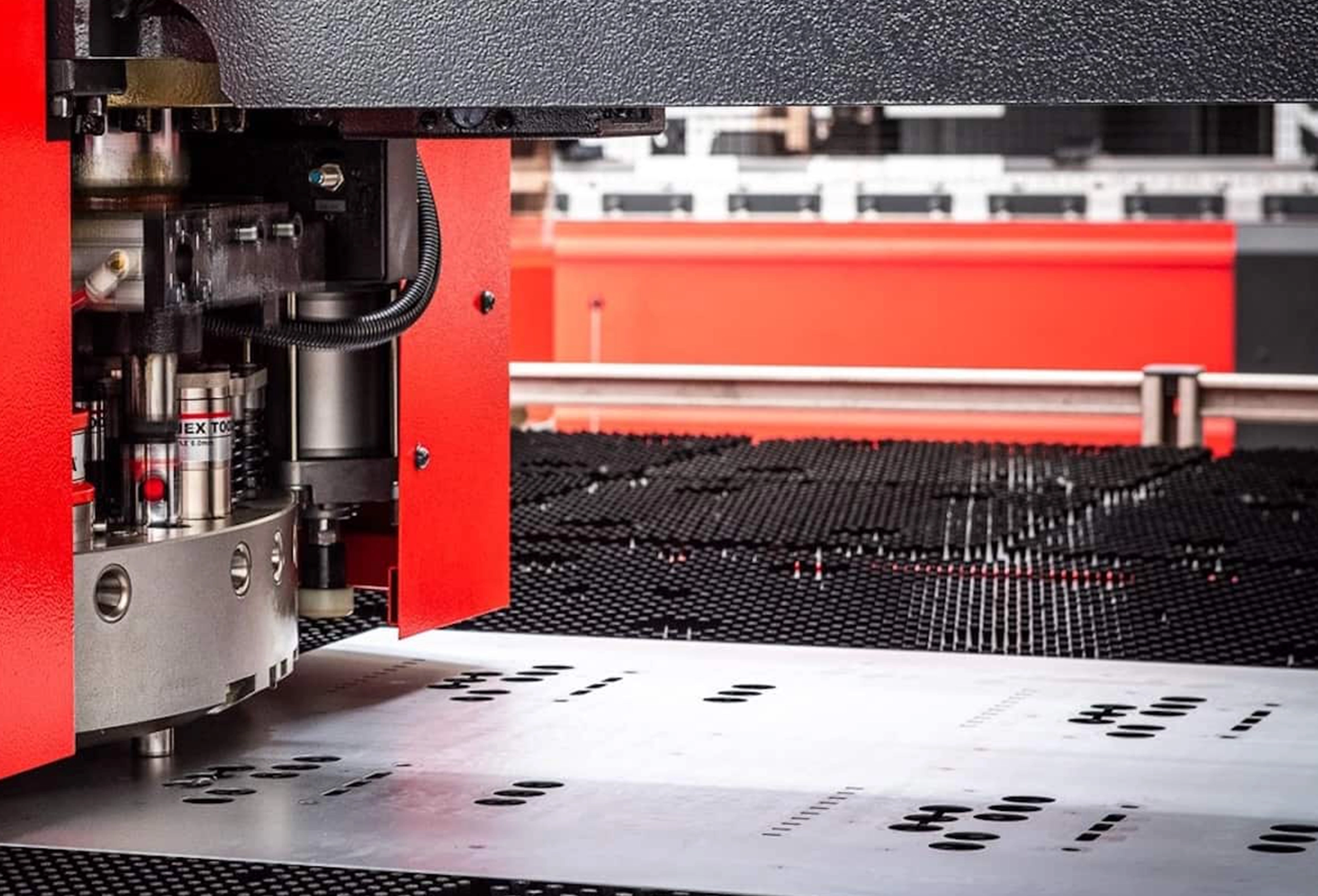

CNC punching services

Our CNC punching process allows for perforating, slotting, threading, and cutting complex shapes at high speed and productivity. It integrates multiple operations into a single process, optimizing time and costs while delivering excellent cost-efficiency.

We process various metals with multiple geometry integrations, making it ideal for functional and ventilated parts.

Based on Your Part Design

- Lead times tailored to your needs

- Optimized precision production

Standard Production

- Scheduled delivery programs

- Consistent and flexible lead times

- Carbon steel up to 6 mm thickness

- Stainless steel up to 3 mm thickness

- Aluminum and copper up to 8 mm thickness

- Width up to 1.5 meters

- Length up to 6.0 meters

CNC bending services

We provide CNC bending for metal parts with precise, numerically controlled forming. We ensure exact angles, tight tolerances, consistent repeatability, and superior dimensional quality, even for complex components.

Accurate angles and radii, reduced material waste, and efficient, continuous production. Ideal for structural and precision parts.

Based on Your Part Design

- Lead times tailored to your needs

- Precision production under CNC control

Standard Production

- Scheduled delivery programs

- Consistent and flexible lead times

- Ideal for higher production volumes

Rolled services

We offer precision plate and sheet rolling services. Cold forming allows us to bend and roll metal sheets and plates using rollers, achieving uniform radii and diameters with high precision and repeatability.

This process is widely used in the fabrication of cylinders, cones, hoppers, and structural components, both for single-piece and series production.

4-Day Prototypes & Small Batches

- Lead times tailored to your needs

- Optimized precision production

Standard Production

- Scheduled delivery programs

- Consistent and flexible lead times

- Carbon steel: 1–50 mm

- Carbon steel: 1–50 mm

- Aluminum: 1–40 mm

- Galvanized steel: 1–10 mm

- Copper / Brass: 0.8–12 mm

production stamping services

Efficient production with high repeatability. We offer metal stamping services, a cold-forming process that allows cutting, punching, and shaping sheet metal using dies and mechanical or hydraulic presses.

Ideal for mass production, ensuring high precision, consistent repeatability, and low cost per part at medium to high volumes.

Based on Your Part Design

- Lead times tailored to your needs

- Optimized precision production

Standard Production

- Scheduled delivery programs

- Consistent and flexible lead times

- Carbon steel: 0.5–6.0 mm

- Stainless steel: 0.5–4.0 mm

- Aluminum: 0.5–8.0 mm

- Copper and brass: 0.5–5.0 mm

High-Precision CNC Sheet Metal Services

We deliver high-precision sheet metal solutions that support demanding industrial operations, combining advanced forming technology, CNC-integrated tooling, and strict quality control to ensure consistent dimensional accuracy.

Our fabrication processes are designed to achieve complex geometries, precise bend angles, and reliable structural integrity across a wide range of production requirements, from CNC-machined prototypes to full-scale industrial manufacturing.

Why Choose Fiesco for Welding services?

- CNC-Integrated Precision

- Advanced Technology

- Multi-Material Expertise

- Strict Quality Control

- Prototype to Production

- Strategic Nearshoring

Sheet Metal Services from mexico to The United States

Full-Service Sheet Metal Solutions From Baja California to the United States

Operating from Baja California, we provide high-precision sheet metal fabrication solutions that support U.S. manufacturers with CNC-accurate forming, tight-tolerance bending, and fast turnaround times.

Our fabrication and assembly processes are designed to meet the most demanding industrial requirements while maintaining cost efficiency and consistent dimensional quality across every batch.

Through our binational operating model, U.S. companies benefit from reliable cross-border manufacturing, close communication, and engineering support that ensures precise results from CNC-integrated prototyping to full-scale production.

Explore Our Advanced CNC Sheet Metal Technology

At FIESCO, we operate state-of-the-art CNC sheet metal systems designed to handle complex forming and bending requirements with accuracy and efficiency. Our advanced equipment, integrated with CNC-programmed tooling, allows us to process a wide range of materials, deliver high-precision bends, and support both custom prototypes and high-volume production runs.

Through this technology, we meet diverse industry requirements while ensuring consistent dimensional quality, fast turnaround times, and reliable on-time delivery to our U.S. partners.

Fiesco Precision

Material Selection & Cost Optimization

Choosing the right material is critical for both performance and cost efficiency.

At Fiesco Precision, our engineering team works with clients to evaluate design requirements, industry standards, and budget considerations to recommend the most effective material options.

This ensures durability, functionality, and cost control across every project.

Smarter Choices, Better Results

Through detailed analysis and supplier integration, we identify materials that balance strength, machinability, and price.

By optimizing both the selection and usage of raw materials, we help reduce waste, control production costs, and keep your projects within budget without compromising on quality.

Let’s Bring Your Vision to Life With High-Precision CNC Sheet Metal Fabrication

Need clean, accurate cuts delivered fast? Fiesco Precision provides reliable laser cutting solutions designed to meet your exact specifications, timelines, and production requirements.