Mold and dies services

Precision Mold and Die solutions

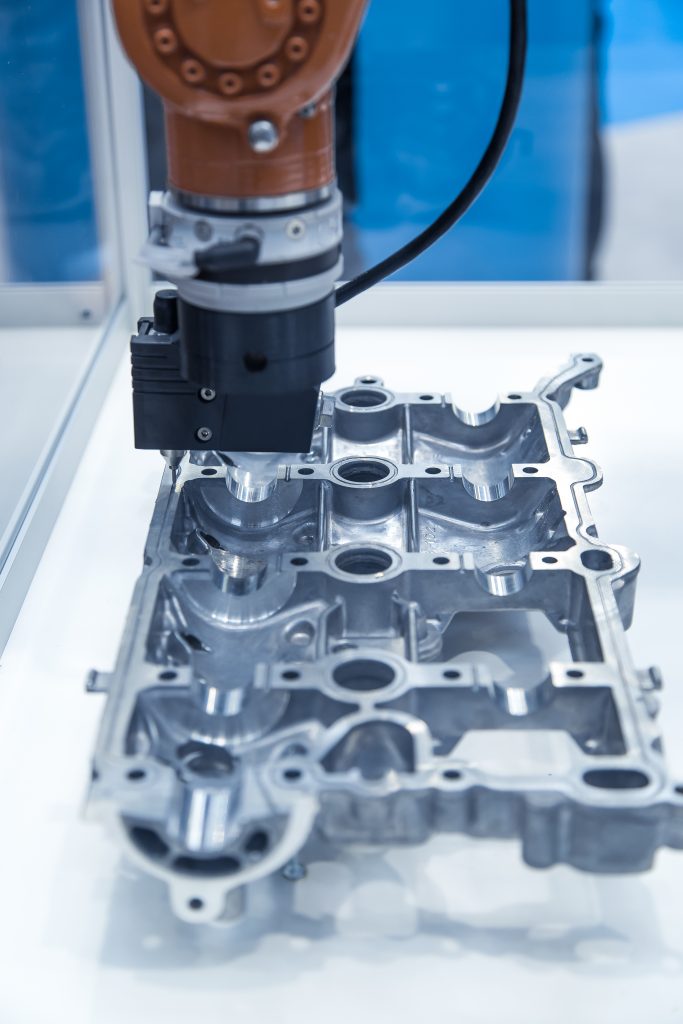

Mold & Die Manufacturing and Repair

We manufacture, repair, and modify molds and dies with high-precision CNC machining, EDM, and grinding processes. Our team ensures tight tolerances, durable tooling, and reliable performance for demanding industrial applications.

From prototype tooling to production molds, we help reduce downtime and keep your manufacturing processes running efficiently.

Molding and Casting services

We turn your designs into reality: advanced solutions in industrial molding and casting.

Looking to optimize your supply chain with high-precision parts?

At Fiesco, we combine cutting-edge technology with engineering expertise to deliver complete plastic molding and casting services. From rapid prototypes to full-scale production, we adapt to the most demanding industry standards.

- High-Speed Injection Molding: Maximum efficiency for high-volume production.

- Precision Casting: Superior finishes and structural strength for complex geometries.

- Mold & Die Design: Extended tooling life and optimized performance.

- Wide Range of Materials: Thermoplastics and alloys.

Stamping services

Comprehensive Stamping and Industrial Maintenance Solutions: Maximum Efficiency for Your Plant

At Fiesco, we offer a complete package of services to ensure the precision and durability of your metal components.

- Precision Stamping: Cutting, punching, and deep-drawing processes with tight tolerances for perfect repeatability in high volumes.

- Custom Manufacturing: We design and produce tooling, molds, and special parts according to your most demanding technical specifications.

- Die and Mold Repair: Diagnostic and restoration services for damaged tools, restoring original functionality and avoiding premature equipment replacement.

- Critical Spare Parts: High-strength replacement components for industrial machinery to keep your production running.

- Reduced Downtime: Fast response for emergency repairs and spare-parts supply.

Fixtures design

We design and manufacture high-performance industrial fixtures that turn slow, unstable processes into fast, repeatable, and profitable production lines.

- Up to 40% shorter cycle times

- Zero positioning errors

- Stable 24/7 production

- Less scrap, less rework, higher profitability

- Faster, safer operators

7 Days

Fixtures for assembly lines, based on design and size

-

1Analyze your problem

-

2Design the solution

-

3CNC manufacturing

-

4Test on your production line

-

5Increase output from day one