Finishing services

CNC-Integrated Finishing Solutions

Advanced CNC Surface Preparation & Manufacturing Solutions

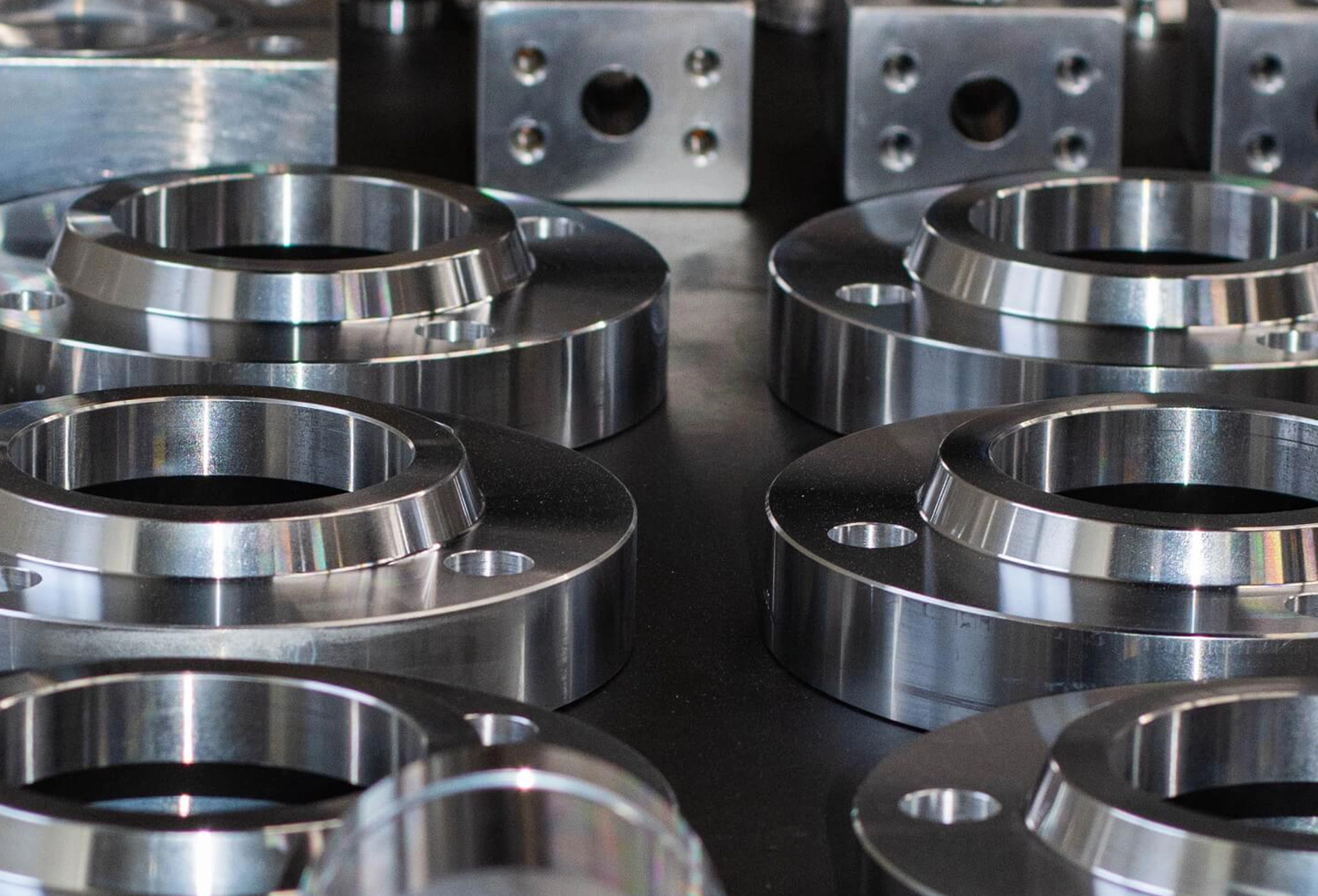

At FIESCO, we bridge the gap between high-performance surface protection and CNC precision. Our integrated approach ensures that every finishing process respects the tight tolerances of the original CNC-machined features, guaranteeing that coatings never compromise the perfect fit-up of your assemblies while maximizing the durability and aesthetic integrity of the final product.

Anodizing services

We offer extensive installed capacity for industrial surface finishing processes, including gloss black and matte black finishes, meeting demanding commercial, military, and aerospace standards. Our capabilities allow us to process parts of various sizes while maintaining consistent quality and performance.

All finishing operations are executed under a certified ISO 9001:2015 quality management system, ensuring full traceability, process consistency, and strict compliance with technical specifications. This provides our customers with the reliability, confidence, and quality assurance required for critical industrial applications.

- Aluminum 1100, 3003, 3004, 3105

- Aluminum 5052, 6061, 6063, and others

- Aluminum alloys

- Titanium (for specialized applications)

- Magnesium (processed under controlled conditions)

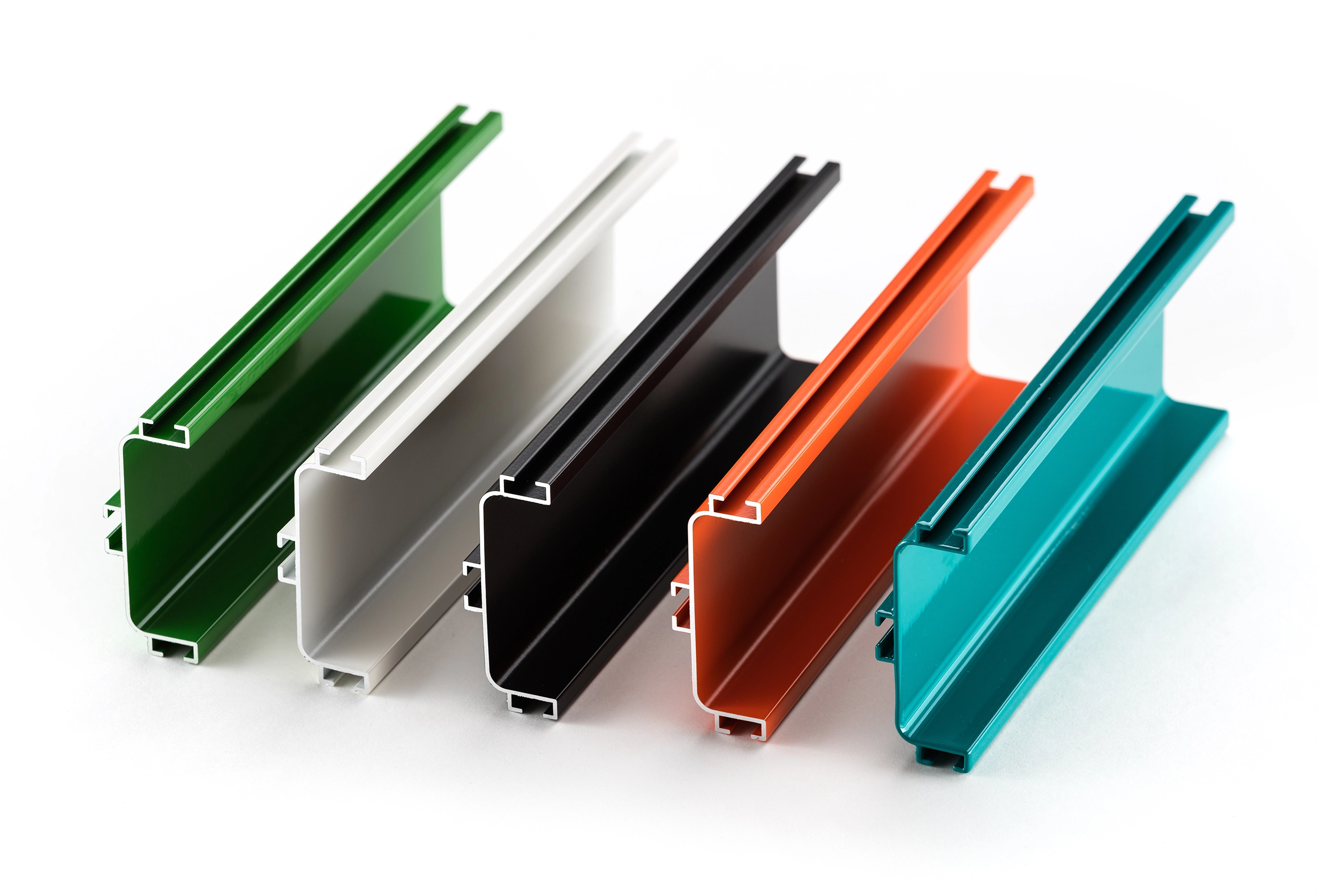

Powder Coating services

We offer extensive experience and strong installed capacity to support your production requirements, including process development and control across color, part size, and batch volumes. Our operations are designed to adapt to your specific manufacturing needs with precision and consistency.

Backed by robust logistics capabilities, we deliver end-to-end manufacturing solutions under strict compliance with our ISO-certified quality management system, ensuring reliability and full process control at every stage.

Working closely with our engineering team, we provide continuous technical, operational, and administrative support to resolve questions efficiently and ensure a well-supported, dependable service throughout the entire project lifecycle.

- Carbon Steel

- Stainless Steel

- Aluminum

- Galvanized Steel

- Iron

- Conductive Metal Alloys

Nickel Plating

We provide reliable solutions for a wide range of nickel finishing processes, fully compliant with international standards such as ASTM B733, ASTM B456, ISO 4527, ISO 4528, MIL-C-26074, and AMS 2404. Our capabilities support demanding industrial, commercial, and aerospace requirements.

Backed by an experienced engineering team, we work closely with our customers to address technical questions and develop finishing processes aligned with specific application needs. Collaboration and technical clarity are central to every project.

All operations are conducted under our ISO-based quality management system, ensuring full process control, traceability, and logistical support to meet customer specifications with consistency and confidence.

- Carbon Steel

- Stainless Steel

- Brass

- Copper

- Bronze

Heat treatment services

We provide heat treatment processes designed to improve the strength, durability, and performance of components, selected according to the material, final application, and real operating conditions. This process helps extend part lifespan and reduce service failures, ensuring reliable performance in demanding industrial applications.

5–7 Day Delivery Depending on Part Features and Volume

Prototype, Low, Medium, and High-Volume Production

Chrome Plating services

We provide installed capacity for both hard chrome plating and decorative chrome finishes, tailored to your specific applications and required industry standards. Our processes are designed to deliver durability, surface performance, and consistent quality across a wide range of components.

Working closely with our engineering team, we support the development and control of your production processes under our ISO 9001:2015–certified quality management system, ensuring reliable results, strict quality compliance, and on-time delivery for every project.

- Aluminum

- Aluminum Alloys

- Zinc

- Zinc Alloys

- Magnesium

Silver & Precious Metal Plating

We offer high installed capacity and strict process control for plating operations, fully aligned with applicable national and international standards. Our processes are designed to deliver consistent surface quality and reliable performance across a wide range of industrial applications.

All operations are conducted under an ISO 9001:2015–certified quality management system, ensuring full compliance with customer requirements, on-time delivery, and process consistency at every stage.

Supported by an experienced engineering team, we provide no-obligation technical assistance, working closely with our customers to ensure product quality from first article approval through continuous production.

- Steel

- Stainless Steel

- Copper

- Brass

- Nickel

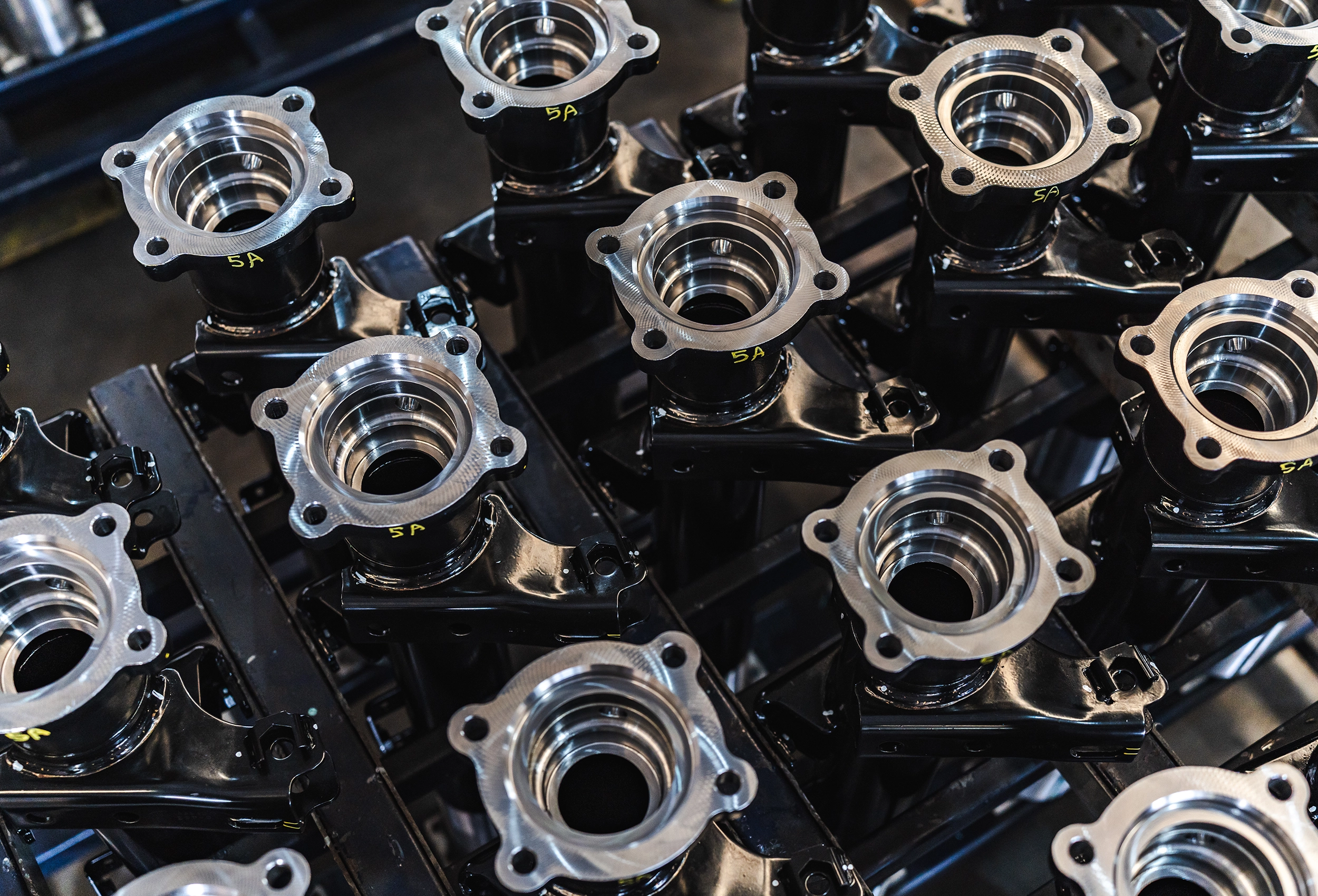

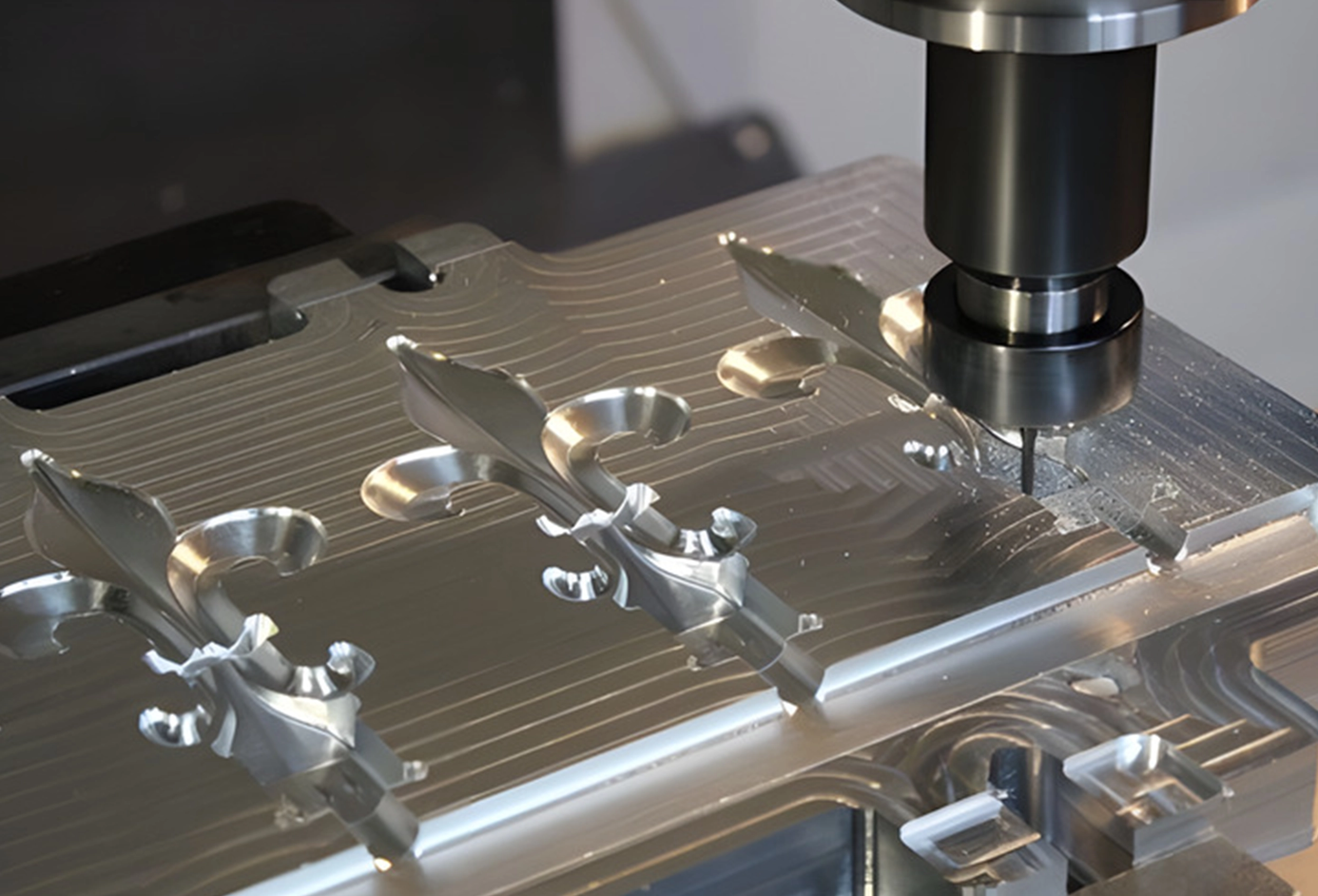

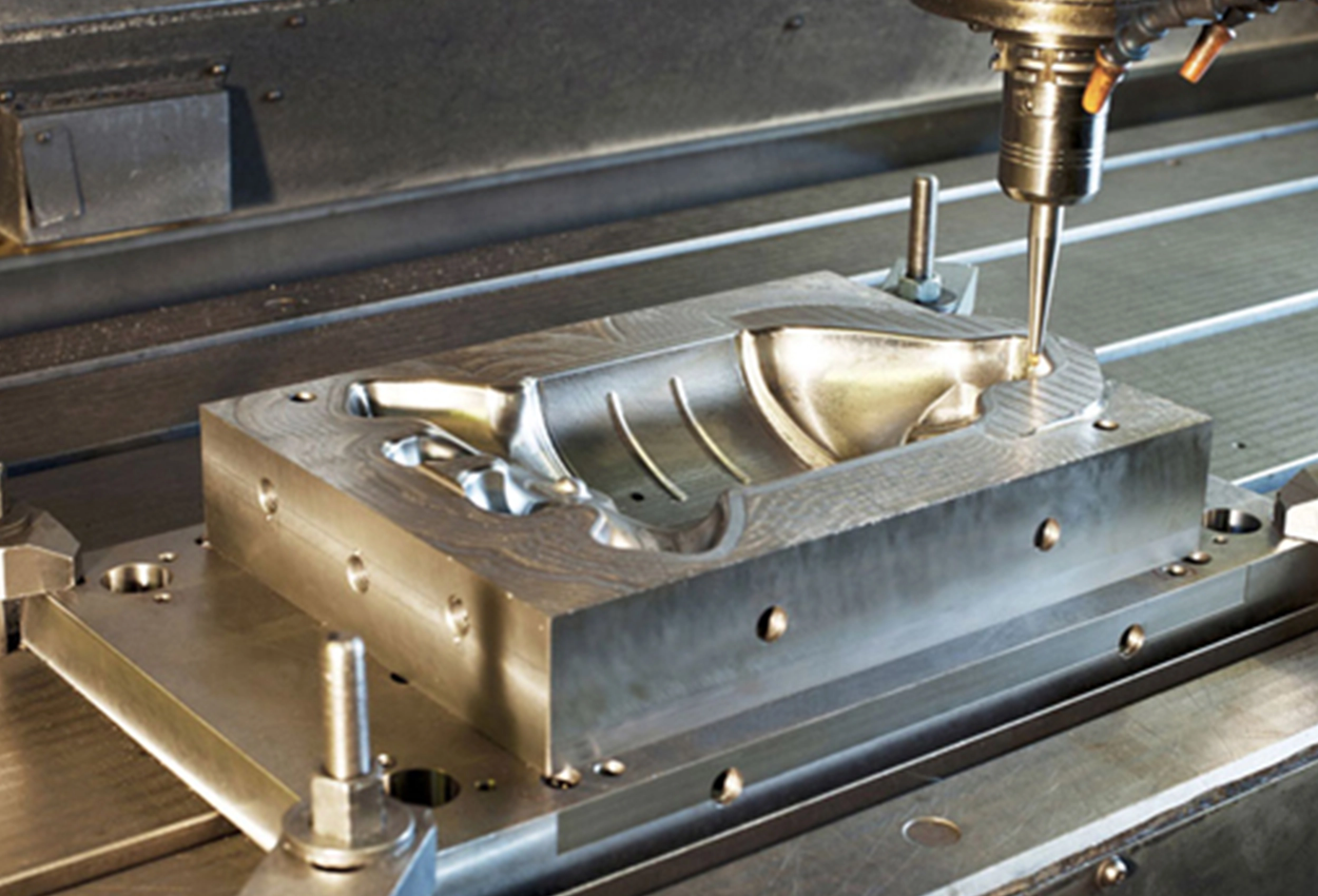

CNC Milling services

We offer specialized high-precision CNC milling capabilities for the manufacture of industrial parts, from single components to full-scale production, working with tight tolerances and competitive lead times.

Our processes are supported by engineering technical assistance, ensuring each part meets real-world plant applications and customer specifications, all under an ISO 9001:2015 quality management system.

Galvanizing services

We provide zinc coating as a durable corrosion-protection solution, ideal for components exposed to moisture, outdoor conditions, and harsh industrial environments.

The process creates an effective barrier over the base metal, extending part lifespan and ensuring reliable performance in demanding applications.

5–7 Days Delivery Depending On Part Features And Volume

Prototype, Low, Medium, And High-Volume Production

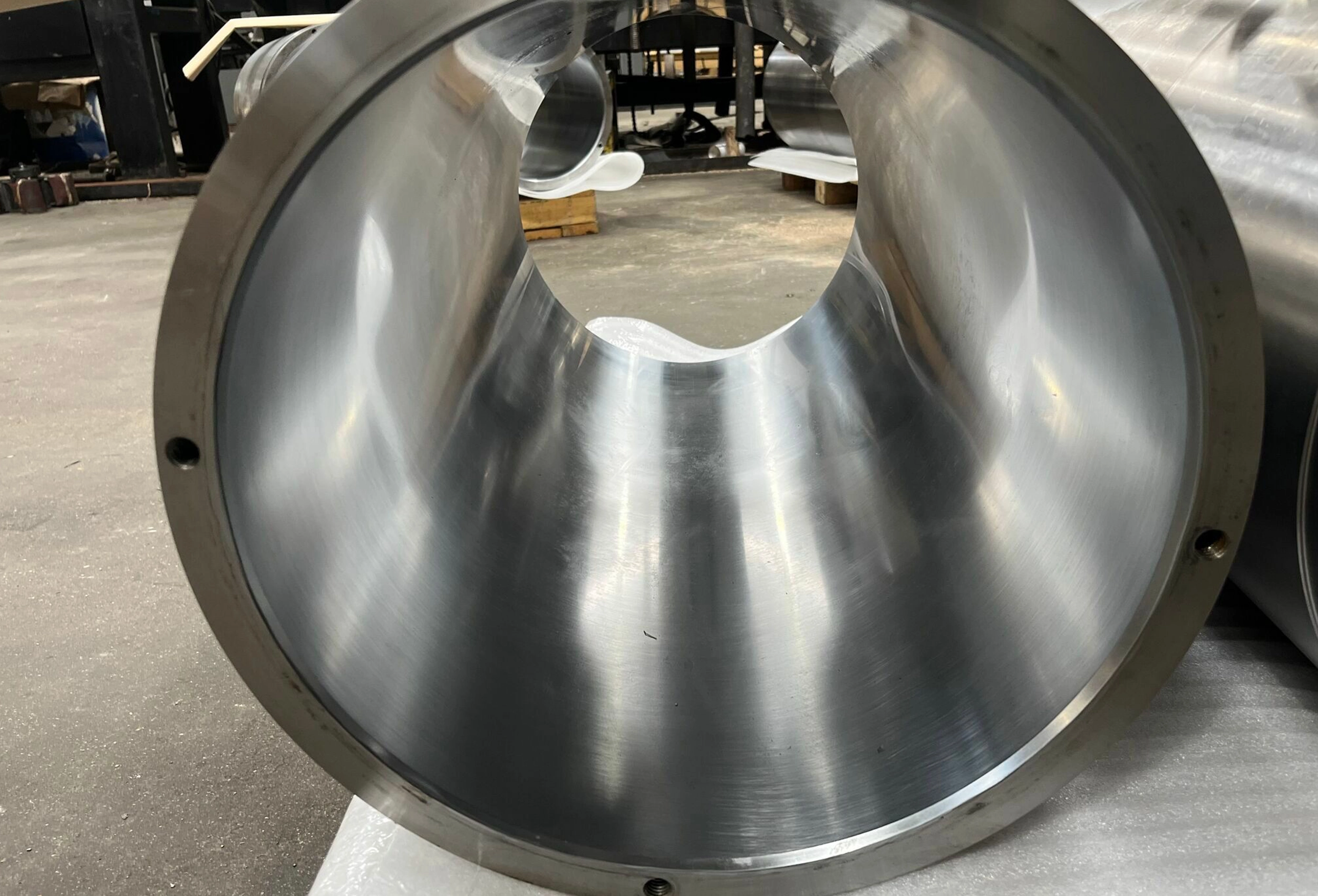

High-Precision CNC Finishing Services

We deliver high-precision finishing and surface solutions that support demanding industrial operations, combining advanced coating technology, CNC-integrated masking, and strict quality control to ensure consistent aesthetic and protective standards.

Our finishing processes are designed to handle complex geometries, preserve tight tolerances, and ensure reliable surface durability across a wide range of production requirements, from CNC-machined prototypes to full-scale industrial manufacturing.

Why Choose Fiesco for Welding services?

- CNC-Integrated Precision

- Advanced Technology

- Multi-Material Expertise

- Strict Quality Control

- Prototype to Production

- Strategic Nearshoring

Finishing Services from mexico to The United States

Full-Service Finishing Solutions From Baja California to the United States

At FIESCO, we offer a complete, binational solution for your surface treatment needs. By integrating finishing directly with our CNC machining and fabrication services, we eliminate the logistical risk of using third-party coaters.

U.S. manufacturers benefit from a single point of contact that manages everything from the initial CNC-programmed manufacturing to the final aesthetic and protective coating. Our proximity to the border ensures that your finished parts—protected by high-quality coatings and strict quality control—are delivered to your facility with the same speed and reliability as a domestic supplier.

Explore Our Advanced CNC Finishing Technology

At FIESCO, we leverage cutting-edge surface finishing technology to manage complex coating and treatment specs with total precision. Our advanced facility, combined with CNC-calibrated processes, allows us to treat a wide array of materials while ensuring a uniform, high-quality finish for everything from custom prototypes to high-volume production runs.

Through this technology, we meet the most stringent industry standards—delivering consistent aesthetic and protective quality, rapid turnaround times, and the reliable on-time delivery our U.S. partners depend on.

Fiesco Precision

Material Selection & Cost Optimization

Choosing the right material is critical for both performance and cost efficiency.

At Fiesco Precision, our engineering team works with clients to evaluate design requirements, industry standards, and budget considerations to recommend the most effective material options.

This ensures durability, functionality, and cost control across every project.

Smarter Choices, Better Results

Through detailed analysis and supplier integration, we identify materials that balance strength, machinability, and price.

By optimizing both the selection and usage of raw materials, we help reduce waste, control production costs, and keep your projects within budget without compromising on quality.

Let’s Bring Your Vision to Life With High-Precision CNC Finishing & Surface Treatment

Need clean, accurate cuts delivered fast? Fiesco Precision provides reliable laser cutting solutions designed to meet your exact specifications, timelines, and production requirements.