Welding

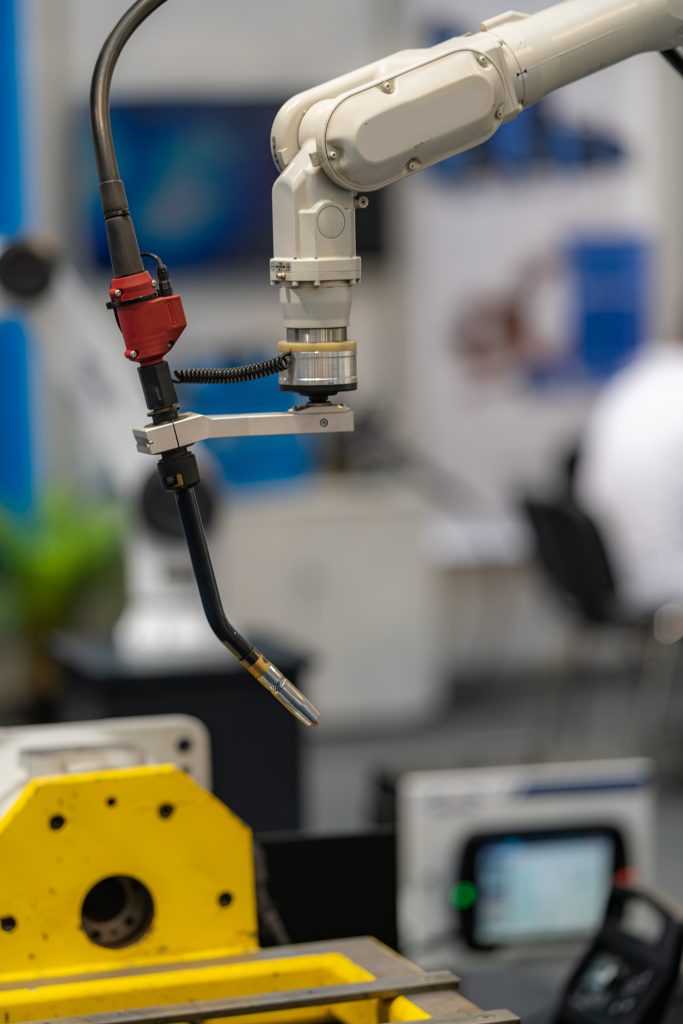

Advanced Welding Solutions

Advanced Welding & CNC Fabrication Solutions

At FIESCO, we bridge the gap between heavy-duty welding and CNC precision. Our integrated approach ensures that every welded assembly starts with CNC-machined components to guarantee perfect fit-up, reducing internal stress and ensuring the structural integrity of the final product.

Carbol Steel

We provide robust welding solutions for carbon steel, utilizing CNC-prepped joints to ensure deep weld penetration. This process is essential for heavy machinery frames and structural components that require the strength of steel combined with the dimensional accuracy of CNC manufacturing.

Delivery times

Materials we work with

- Aluminum (6061, 7075, etc.)

- Carbon Steel (A36, 1018, 1045, etc.)

- Alloy Steels (4140, 4340)

- Tool Steels (A2, D2, O1, H13, S7, P20, M2, etc.)

- Stainless Steel (304, 316)

- Brass / Copper

- Engineering Plastics (Delrin/POM, Nylon, UHMW, PTFE/Teflon, PVC, Polyethylene, PMMA, Polycarbonate)

Stainless Steel

Our TIG welding for stainless steel is designed for industries where precision is non-negotiable. By using CNC-machined fixtures, we maintain strict alignment during the welding process, preventing warping and ensuring a surgical-grade finish for medical and food-processing equipment.

Delivery times

Materials wework with

- Aluminum (6061, 7075, etc.)

- Carbon Steel (A36, 1018, 1045, etc.)

- Alloy Steels (4140, 4340)

- Tool Steels (A2, D2, O1, H13, S7, P20, M2, etc.)

- Stainless Steel (304, 316)

- Brass / Copper

- Engineering Plastics (Delrin/POM, Nylon, UHMW, PTFE/Teflon, PVC, Polyethylene, PMMA, Polycarbonate)

Aluminum

Welding aluminum requires extreme thermal control. We pair our expert welders with CNC-milled heat sinks and jigs to manage heat dissipation, resulting in high-strength, lightweight assemblies for the aerospace and automotive sectors across California.

Delivery times

Materials wework with

- Aluminum (6061, 7075, etc.)

- Carbon Steel (A36, 1018, 1045, etc.)

- Alloy Steels (4140, 4340)

- Tool Steels (A2, D2, O1, H13, S7, P20, M2, etc.)

- Stainless Steel (304, 316)

- Brass / Copper

- Engineering Plastics (Delrin/POM, Nylon, UHMW, PTFE/Teflon, PVC, Polyethylene, PMMA, Polycarbonate)

Laser Welding

Our CNC-driven Laser Welding technology offers a level of accuracy that traditional methods cannot match. This high-speed, automated process delivers a narrow, deep weld with a minimal heat-affected zone, perfect for delicate electronic enclosures and high-precision mechanical sensors.

Delivery times

Materials wework with

- Aluminum (6061, 7075, etc.)

- Carbon Steel (A36, 1018, 1045, etc.)

- Alloy Steels (4140, 4340)

- Tool Steels (A2, D2, O1, H13, S7, P20, M2, etc.)

- Stainless Steel (304, 316)

- Brass / Copper

- Engineering Plastics (Delrin/POM, Nylon, UHMW, PTFE/Teflon, PVC, Polyethylene, PMMA, Polycarbonate)

Specialized Welding

For complex projects involving exotic alloys or hardfacing, FIESCO provides specialized welding services. We often perform post-weld CNC machining on these components to restore critical tolerances that may have shifted during the thermal process, ensuring a 100% accurate final part.

Delivery times

Materials wework with

- Aluminum (6061, 7075, etc.)

- Carbon Steel (A36, 1018, 1045, etc.)

- Alloy Steels (4140, 4340)

- Tool Steels (A2, D2, O1, H13, S7, P20, M2, etc.)

- Stainless Steel (304, 316)

- Brass / Copper

- Engineering Plastics (Delrin/POM, Nylon, UHMW, PTFE/Teflon, PVC, Polyethylene, PMMA, Polycarbonate)

High-Precision Welding Services

We deliver high-precision welding solutions that support demanding industrial operations, combining advanced joining technology, CNC-integrated fixtures, and strict quality control to ensure consistent structural integrity.

Our welding processes are designed to achieve high-strength bonds, clean seams, and reliable dimensional accuracy across a wide range of production requirements, from CNC-machined prototypes to full-scale industrial manufacturing.

Why Choose Fiesco for Welding services?

- CNC-Integrated Precision

- Advanced Technology

- Multi-Material Expertise

- Strict Quality Control

- Prototype to Production

- Strategic Nearshoring

Welding services from mexico to The United States

Full-Service Welding Solutions From Baja California to the United States

Operating from Baja California, we provide high-precision welding solutions that support U.S. manufacturers with high-strength joints, CNC-accurate fixturing, and fast turnaround times.

Our welding and fabrication processes are designed to meet the most demanding industrial requirements while maintaining cost efficiency and consistent structural integrity across every assembly.

Through our binational operating model, U.S. companies benefit from reliable cross-border manufacturing, close communication, and engineering support that ensures precise results from CNC-integrated prototyping to full-scale production.

Explore Our Advanced Welding Technology

At FIESCO, we operate state-of-the-art welding systems designed to handle complex assembly requirements with accuracy and efficiency. Our advanced equipment, integrated with CNC-machined fixtures, allows us to process a wide range of materials, deliver high-strength clean seams, and support both custom prototypes and high-volume production runs.

Through this technology, we meet diverse industry requirements while ensuring consistent structural quality, fast turnaround times, and reliable on-time delivery to our U.S. partners.

Fiesco Precision

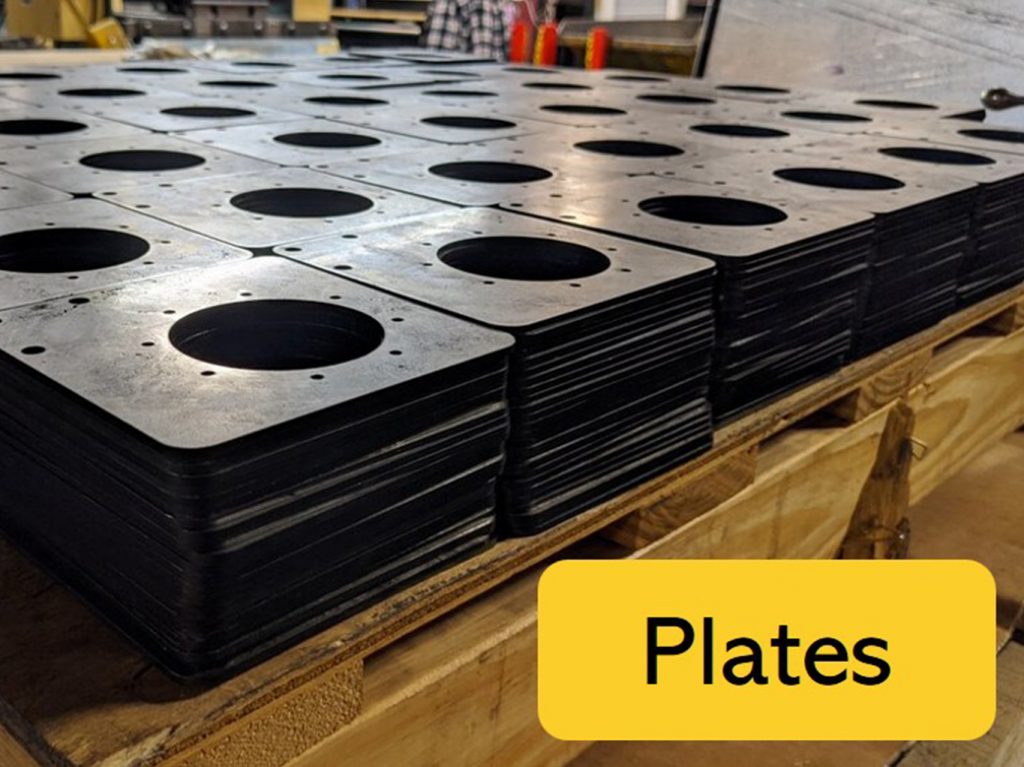

Material Selection & Cost Optimization

Choosing the right material is critical for both performance and cost efficiency.

At Fiesco Precision, our engineering team works with clients to evaluate design requirements, industry standards, and budget considerations to recommend the most effective material options.

This ensures durability, functionality, and cost control across every project.

Smarter Choices, Better Results

Through detailed analysis and supplier integration, we identify materials that balance strength, machinability, and price.

By optimizing both the selection and usage of raw materials, we help reduce waste, control production costs, and keep your projects within budget without compromising on quality.

Let’s Bring Your Vision to Life With High-Precision CNC Welding

Need clean, accurate cuts delivered fast? Fiesco Precision provides reliable laser cutting solutions designed to meet your exact specifications, timelines, and production requirements.