Choosing between CNC machining and laser cutting is a critical decision in industrial manufacturing. Each process offers unique advantages depending on part geometry, material thickness, tolerance requirements, and production volume.

At FIESCO, both CNC machining and laser cutting are used strategically to meet the needs of diverse industries.

https://fiesco.mx/

CNC Machining: Strengths and Applications

CNC machining removes material using cutting tools, making it ideal for:

- Tight tolerances

- Complex 3D geometries

- Thick materials

- Structural components

Best for:

Mechanical assemblies, automotive components, medical devices, construction parts.

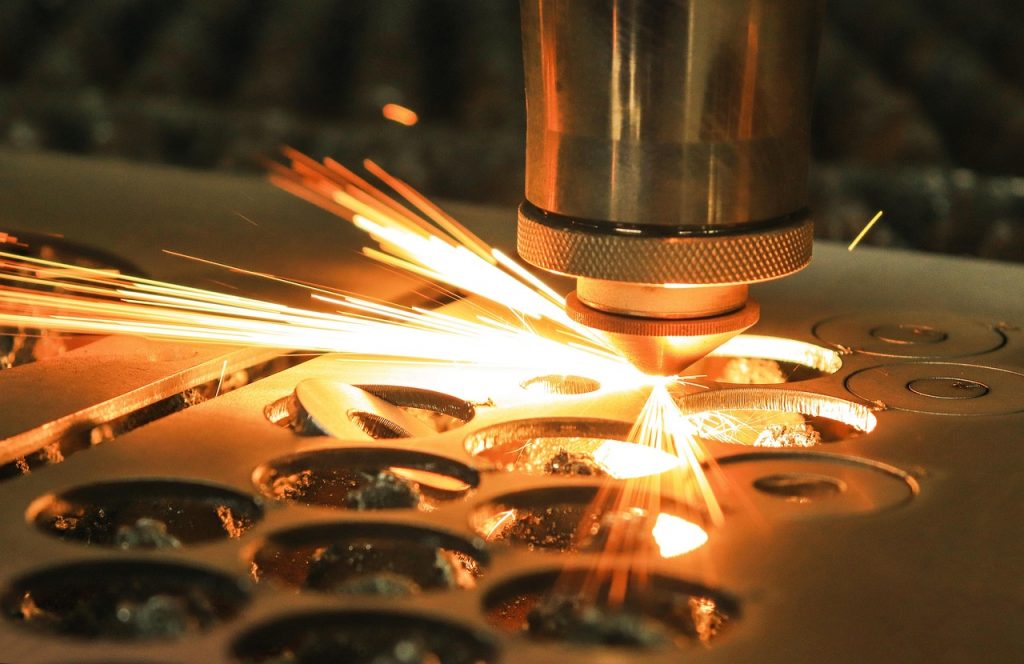

Laser Cutting: Strengths and Applications

Laser cutting uses a focused beam to cut flat materials quickly and efficiently.

Advantages include:

- High-speed production

- Clean edges

- Minimal material waste

- Cost-effective for flat parts

Best for:

Sheet metal components, brackets, panels, enclosures.

Key Differences at a Glance

| Factor | CNC Machining | Laser Cutting |

|---|---|---|

| Geometry | 3D parts | Flat parts |

| Tolerances | Very tight | Moderate |

| Thickness | High | Limited |

| Finish | Machined | Heat-affected edge |

Industry Applications

- Automotive Industry:

https://fiesco.mx/industries/automotive-industry/ - Mechanical Industry:

https://fiesco.mx/industries/mechanical-industry/ - Construction Equipment:

https://fiesco.mx/industries/construction-industry/

Why FIESCO Uses Both

By combining laser cutting and CNC machining, FIESCO delivers efficient, precise, and cost-effective solutions tailored to each project.

📩 Get expert guidance:

https://fiesco.mx/contact/