Food Industry CNC Services in California

Precision CNC Manufacturing for

Food-Processing Equipment

High-precision machining and manufacturing solutions for food-grade equipment and industrial processing systems.

Supporting Food Industry Production Across California

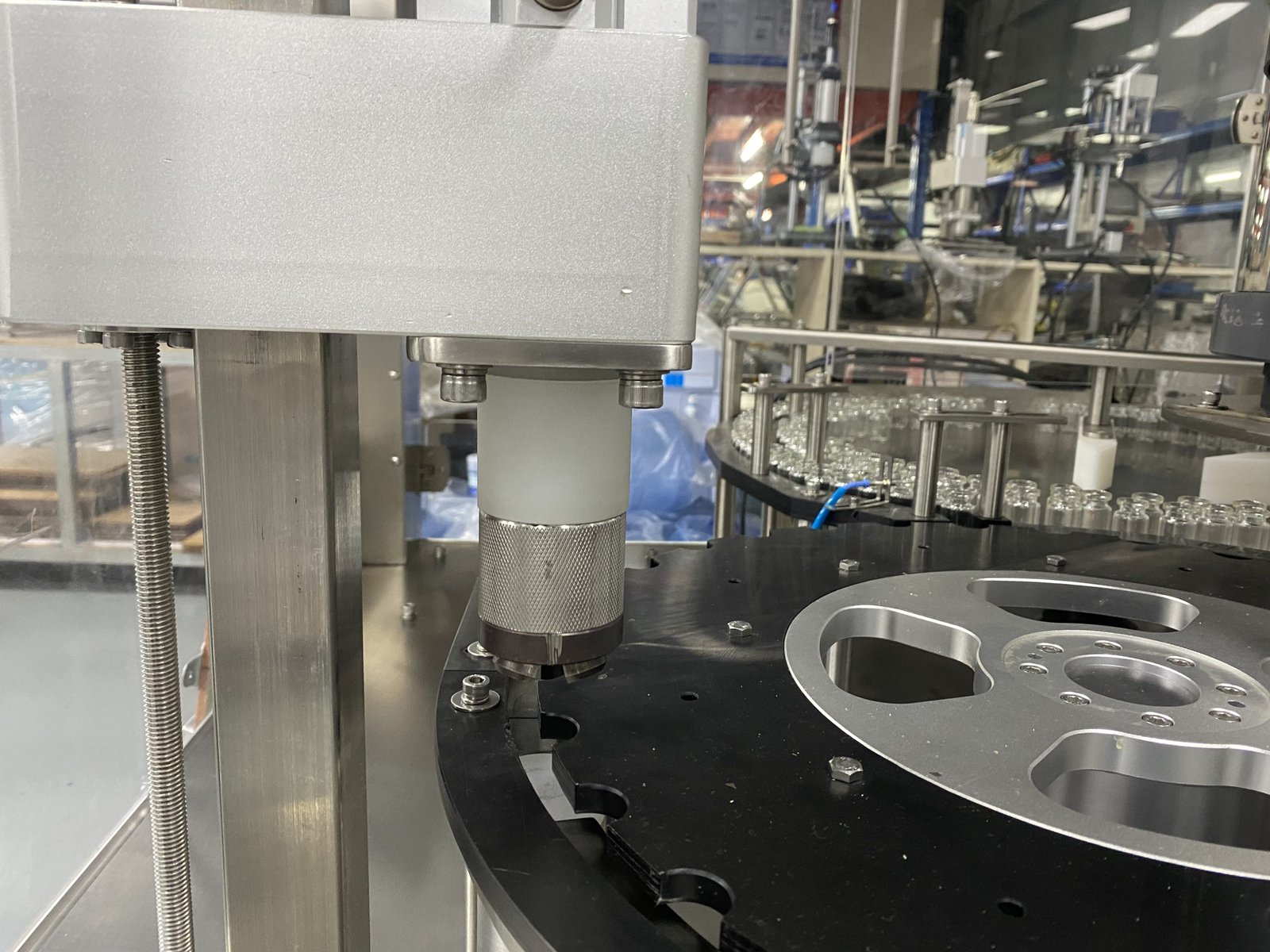

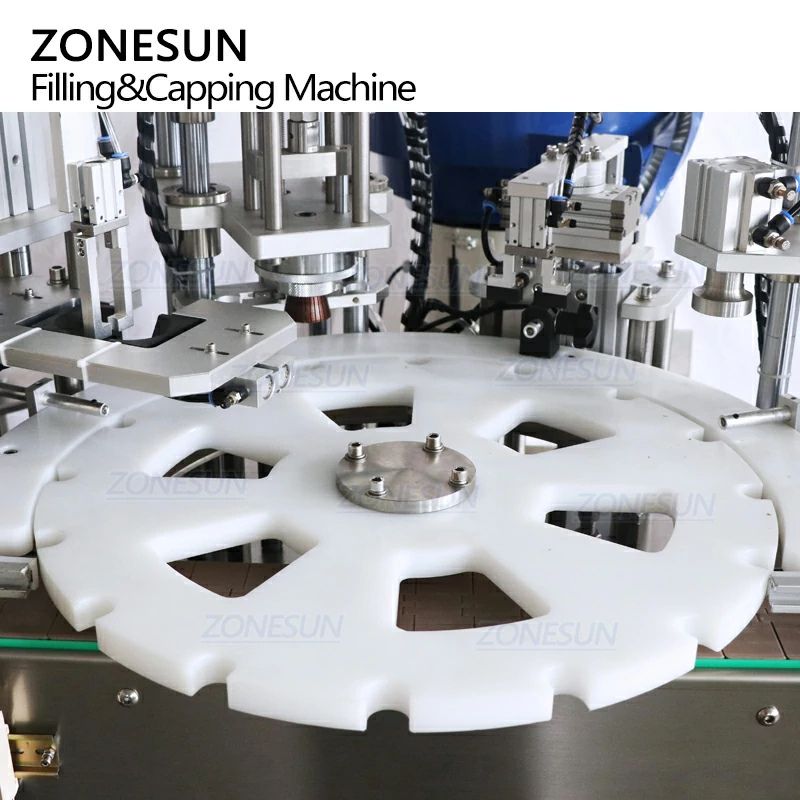

The food industry cannot afford downtime. Production demands in California’s food manufacturing sector are driven by strict consumer expectations, regulatory requirements, and the need for continuous operational efficiency. At FIESCO, we work closely with food manufacturers across California to develop CNC manufacturing solutions that meet these demands while aligning with each customer’s specific production needs.

We have extensive experience machining food-grade materials commonly used by California-based food processors, including aluminum in multiple grades and finishes, engineering plastics, and machinery-grade steels for food-processing equipment and production systems.

Our engineering team collaborates with food industry manufacturers throughout California to improve equipment performance, maintain plant uptime, and ensure full compliance with material, hygiene, and safety standards across every stage of the manufacturing process.

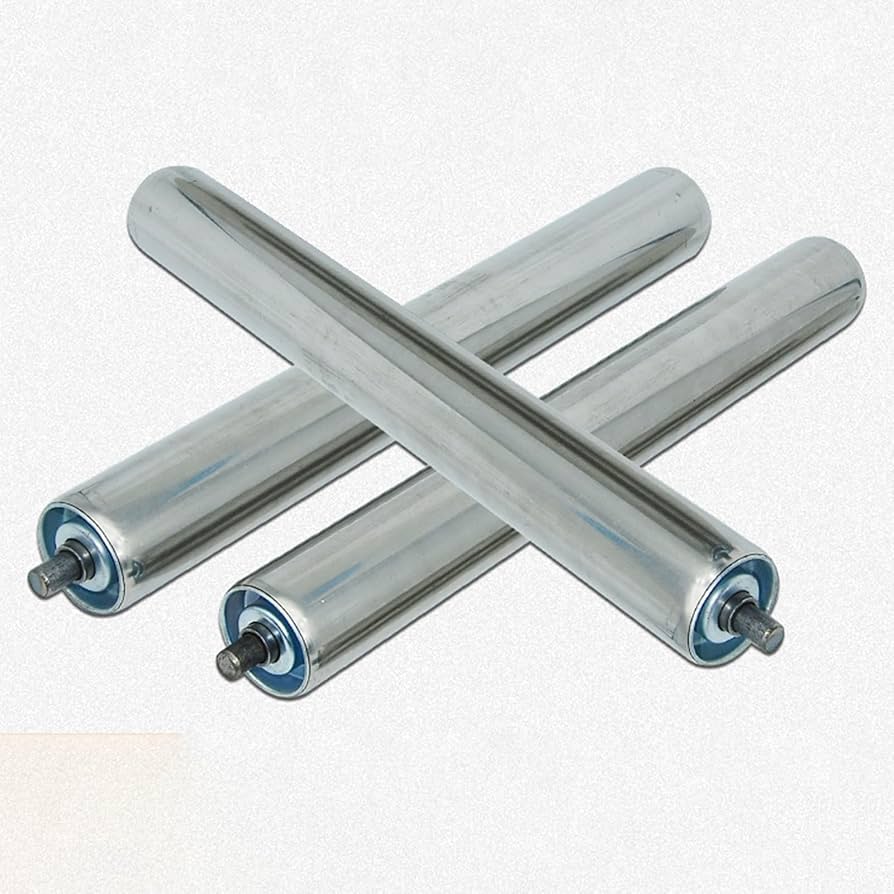

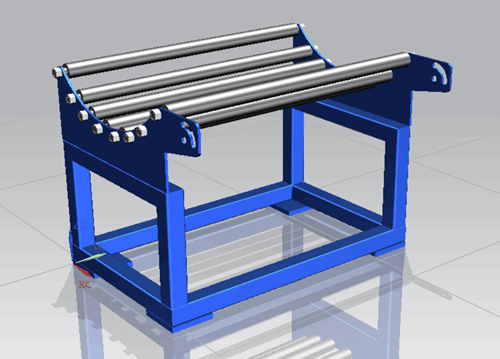

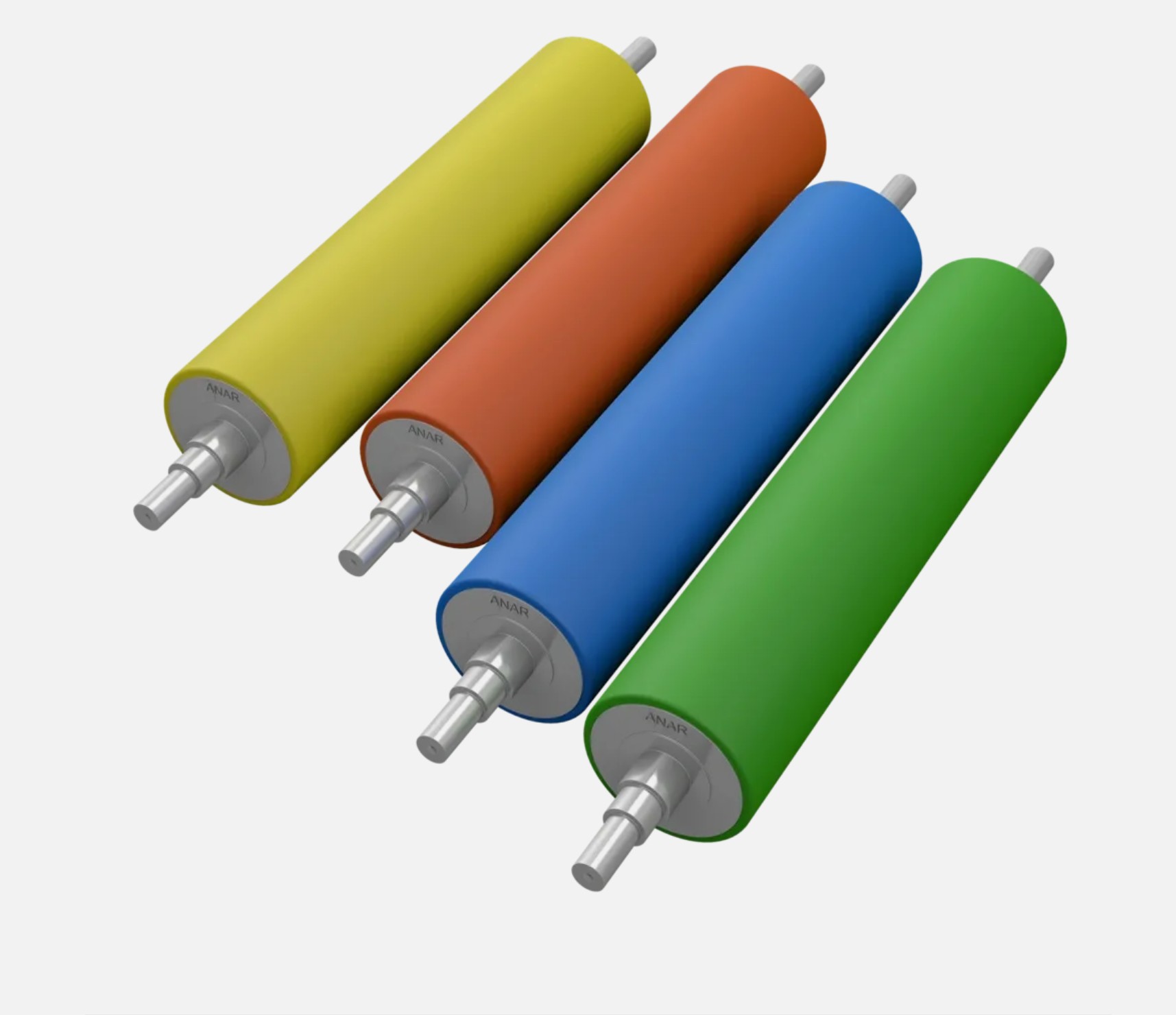

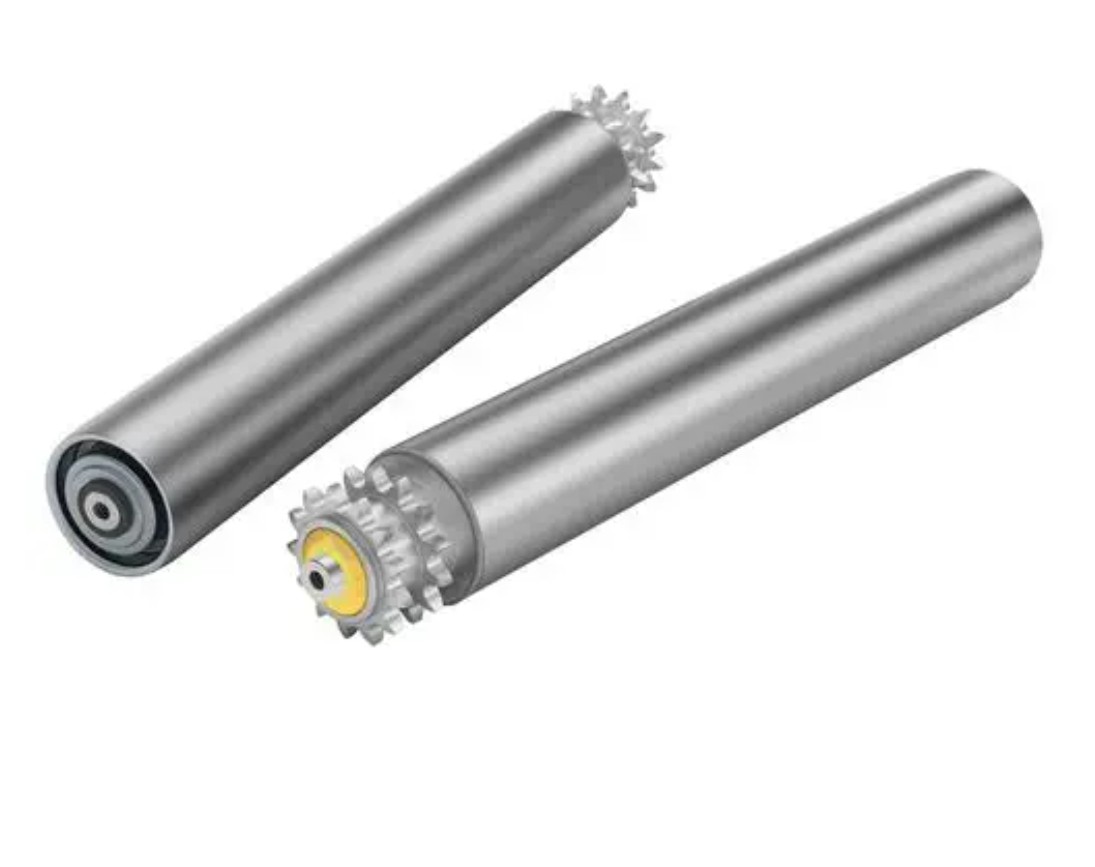

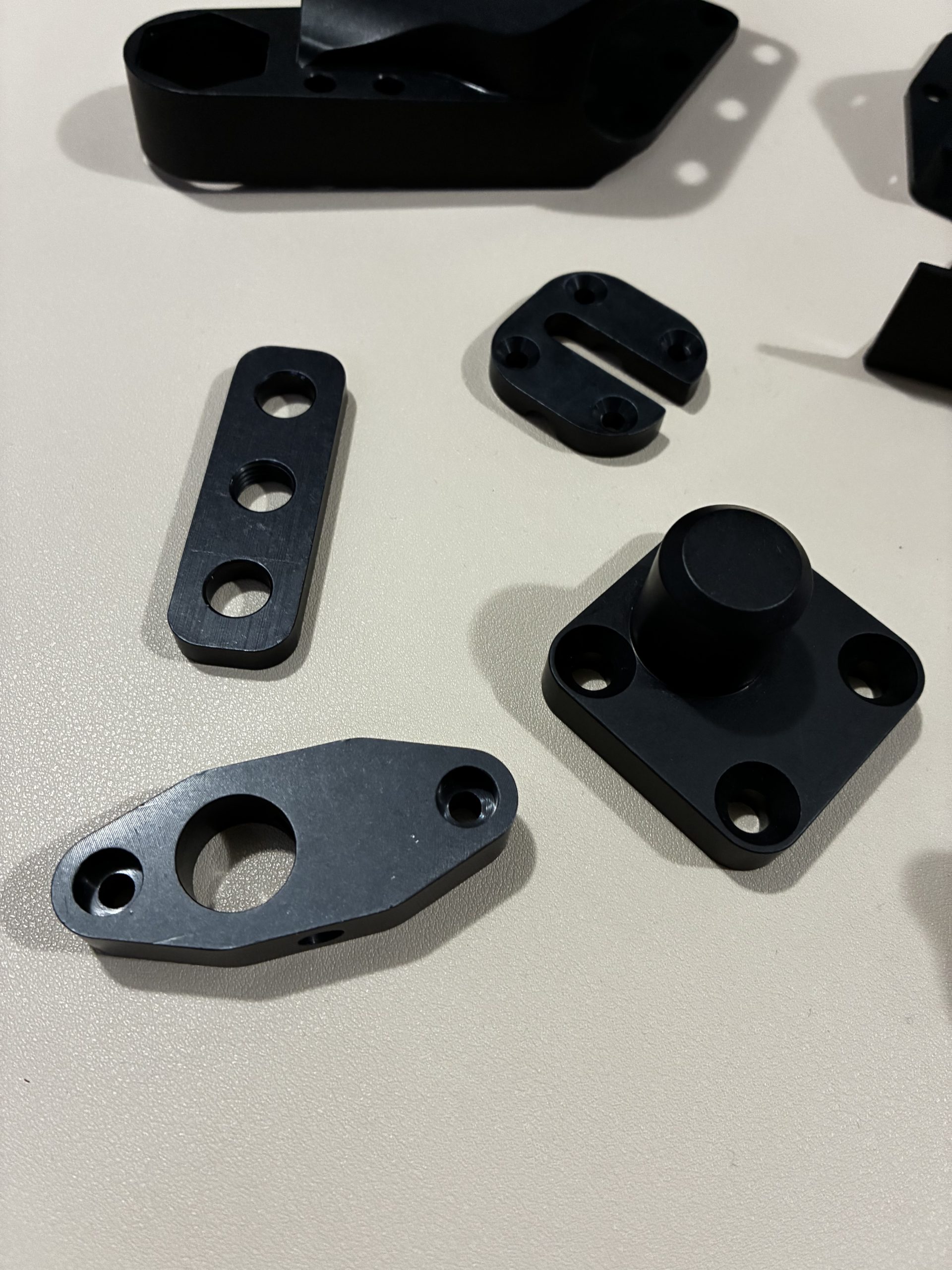

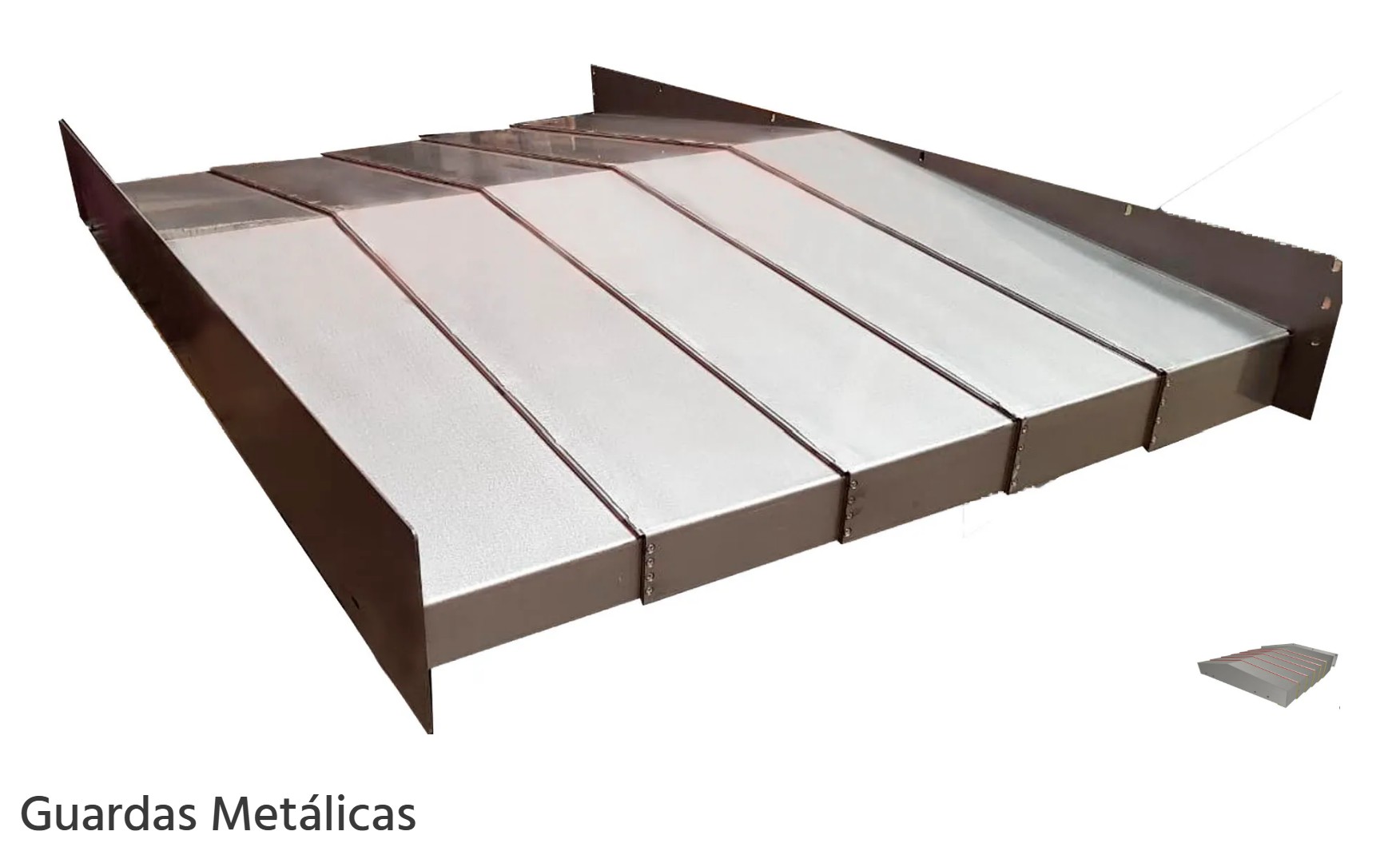

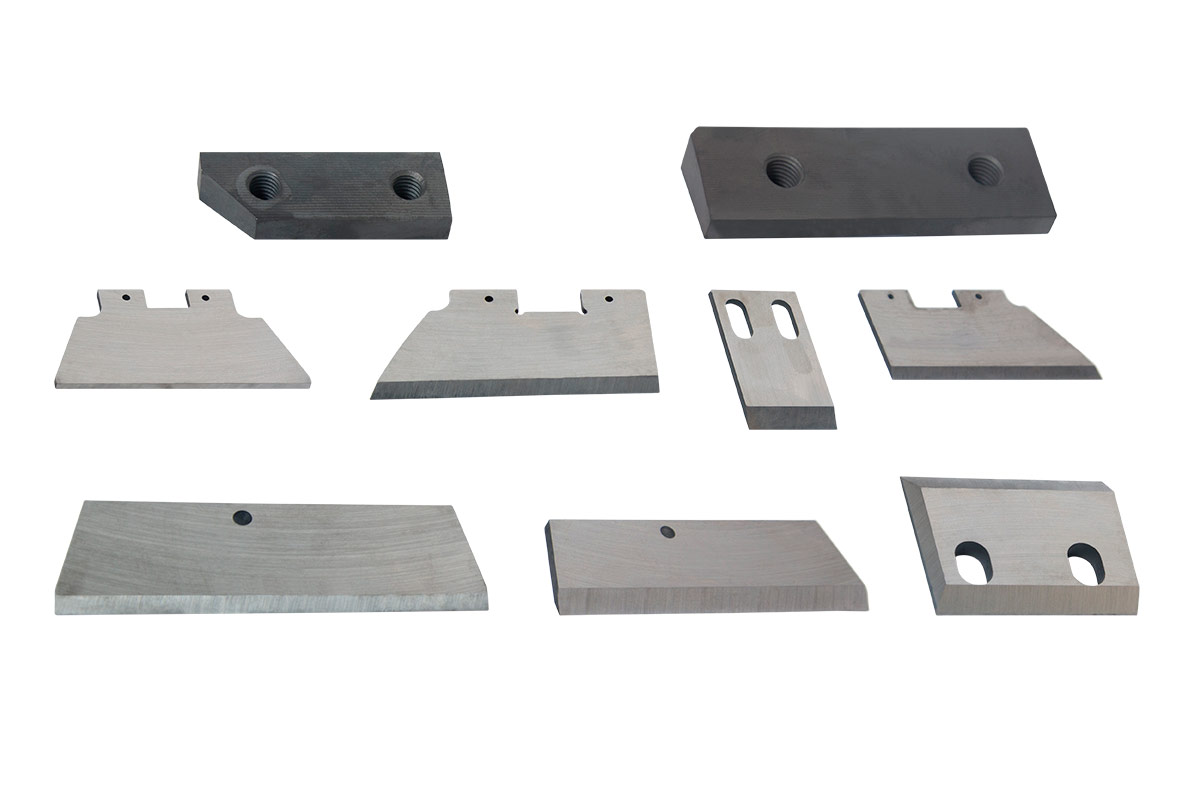

Equipment & Component Manufacturing

We specialize in manufacturing conveyors, metal rollers, transmission rollers, idler rollers, rollers with various coatings or vulcanized rollers, bearings, blades, hoppers, conveyor belts, partitions, etc. We are also committed to working with our regional, national, and international business partners to expedite the supply of raw materials, tools, and accessories. Our processes:

Laser cutting, various welding processes, stainless steel hard coating, arc welding, gas welding, aluminum welding, plasma cutting, guillotine cutting, bending, machining, stamping, engraving, etc.

Our engineering team is distinguished by its close collaboration with our clients, orchestrating internal and external processes, materials, supplies, and finishes to find the best process solutions together, as well as the continuous improvement of processes and tooling to achieve greater profitability.

Whether clients need replacements, upgrades, or new equipment parts, we deliver solutions focused on precision, hygiene, and long-term reliability.

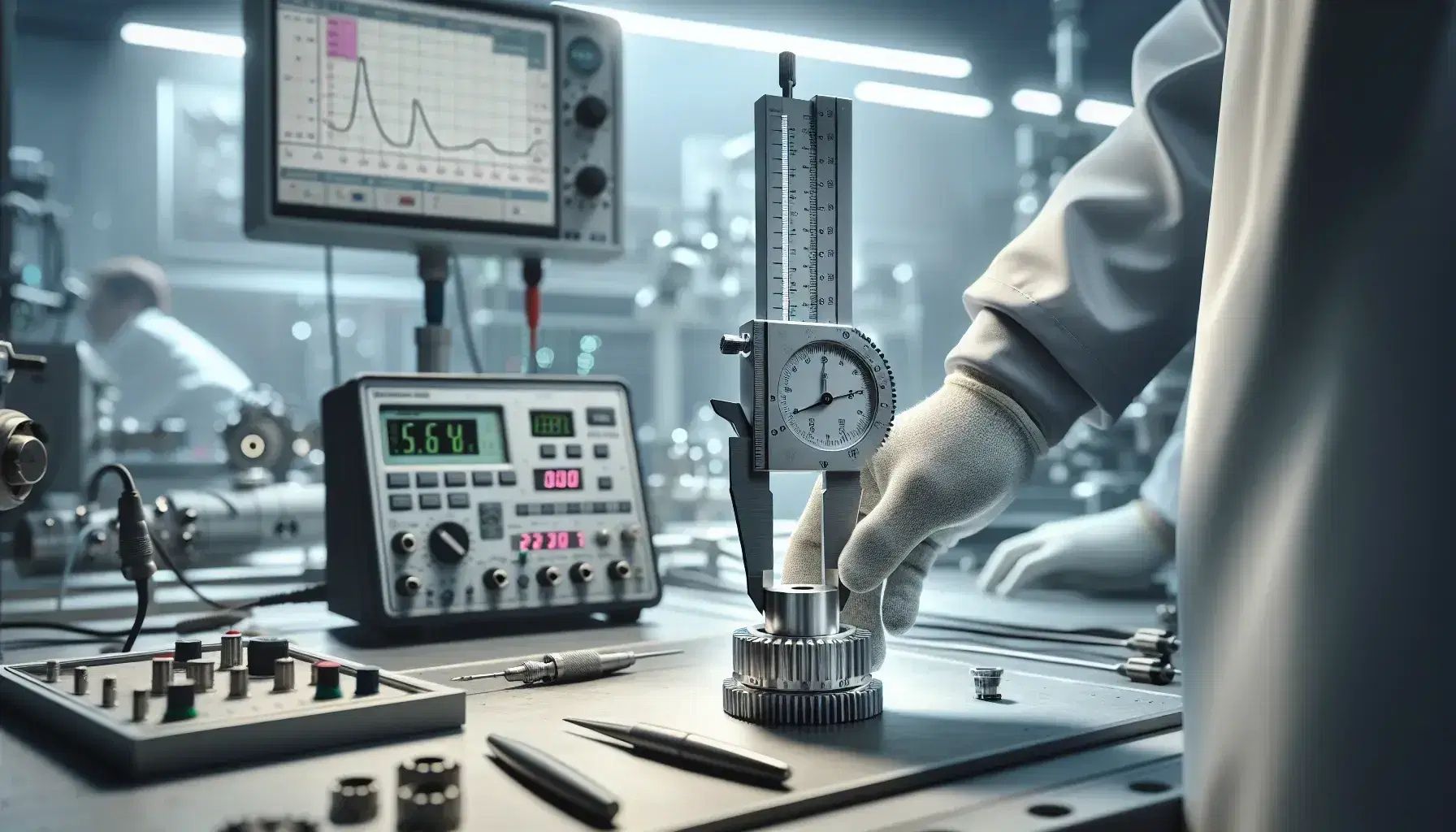

Quality is at the heart of everything we do at Fiesco Precision

Fabrication & Production Capabilities

Fiesco Precision integrates multiple production processes to support fast, high-quality manufacturing for food industry equipment. Our capabilities ensure accurate results and compatibility with existing systems.

Capabilities include:

Laser cutting, plasma cutting, and guillotine cutting

Food-grade welding and fabrication

Metal forming and bending

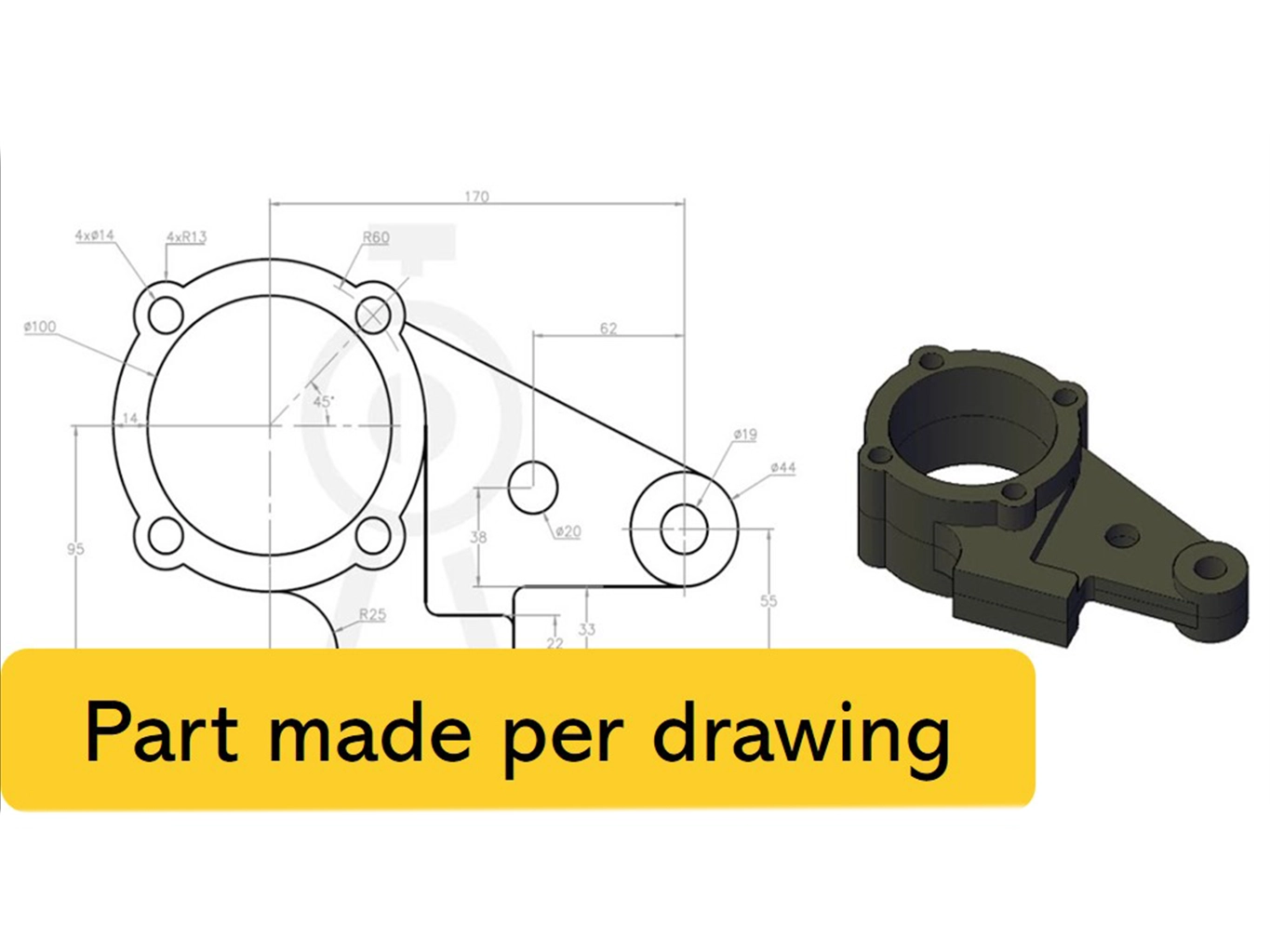

CNC machining for precise, high-accuracy components

Common Food-Processing Parts We Manufacture

Conveyors and conveyor belts

Metal and coated rollers

Industrial blades and bearings

Hoppers, partitions, and auxiliary components

Food industry Customized parts

Food-Grade Materials Expertise

We work with a wide range of materials required for sanitary and high-demand food environments, including stainless steels for food use, engineering plastics, aluminum grades, and coated or vulcanized rollers.

Our partnerships with suppliers at regional, national, and international levels ensure fast access to materials, tools, and accessories when needed.

Engineering Collaboration for Better Performance

Our engineering team partners with clients to refine designs, optimize tooling, and improve production processes. Through hands-on collaboration, we help increase efficiency, extend equipment life, and enhance overall profitability.

This continuous-improvement approach ensures every component meets the functional and hygienic requirements of the food industry.

Reliable Food-Grade CNC Manufacturing in California

Get high-precision components engineered for durability, hygiene, and long-term performance in food processing environments.